Composite wall body material

A composite wall and aluminum alloy profile technology, which is applied to building materials, walls, building components, etc., can solve the problems of no recycling, large errors, and low installation efficiency, so as to reduce on-site construction and management personnel, and protect green and energy-saving Environmental protection and high installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 1 pic 1,、、 and 1 1 ; pic 2 pic 1, specific Embodiment approach

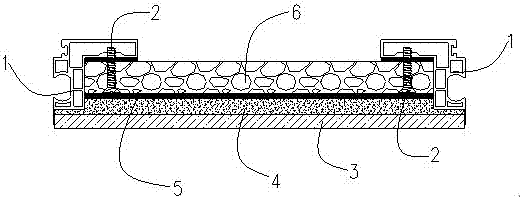

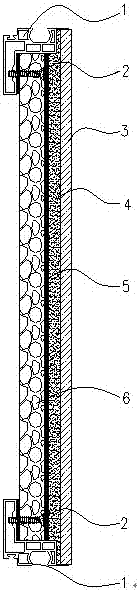

[0018] figure 1 As shown, it is Embodiment 1 of the present invention: a schematic diagram of a horizontal splicing structure of a composite wall figure 1 , the composite wall material is composed of aluminum alloy profiles, cement fiber boards, ceramic tiles, waterproof glue and tile glue fixed together by countersunk flat machine screws to form a composite wall; figure 2 Schematic diagram of the longitudinal splicing structure of this composite wall figure 1 , its specific implementation is as follows:

[0019] 1. First, make screw holes on the cement fiberboard, and screw them together with countersunk flat machine screws;

[0020] 2. Then apply waterproof glue on the cement fiberboard first, and then apply tile glue;

[0021] 3. Next, tiles are placed to make the upper and lower wall materials fit together seamlessly, forming a new type of composite wall.

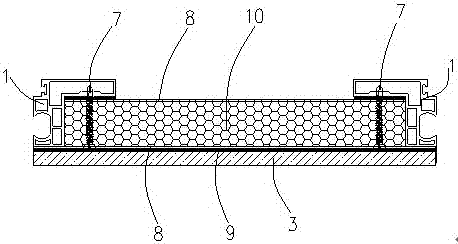

[0022] image 3 As shown, it is Embodiment 2 of the present invention: a schematic diagram of a horizontal spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com