Coaxial cable for low frequency

A coaxial cable and low-frequency technology, applied in the field of coaxial cables, can solve problems such as not being able to effectively reflect the concise structure, and achieve the effects of reducing material consumption, saving resources, and facilitating on-site construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

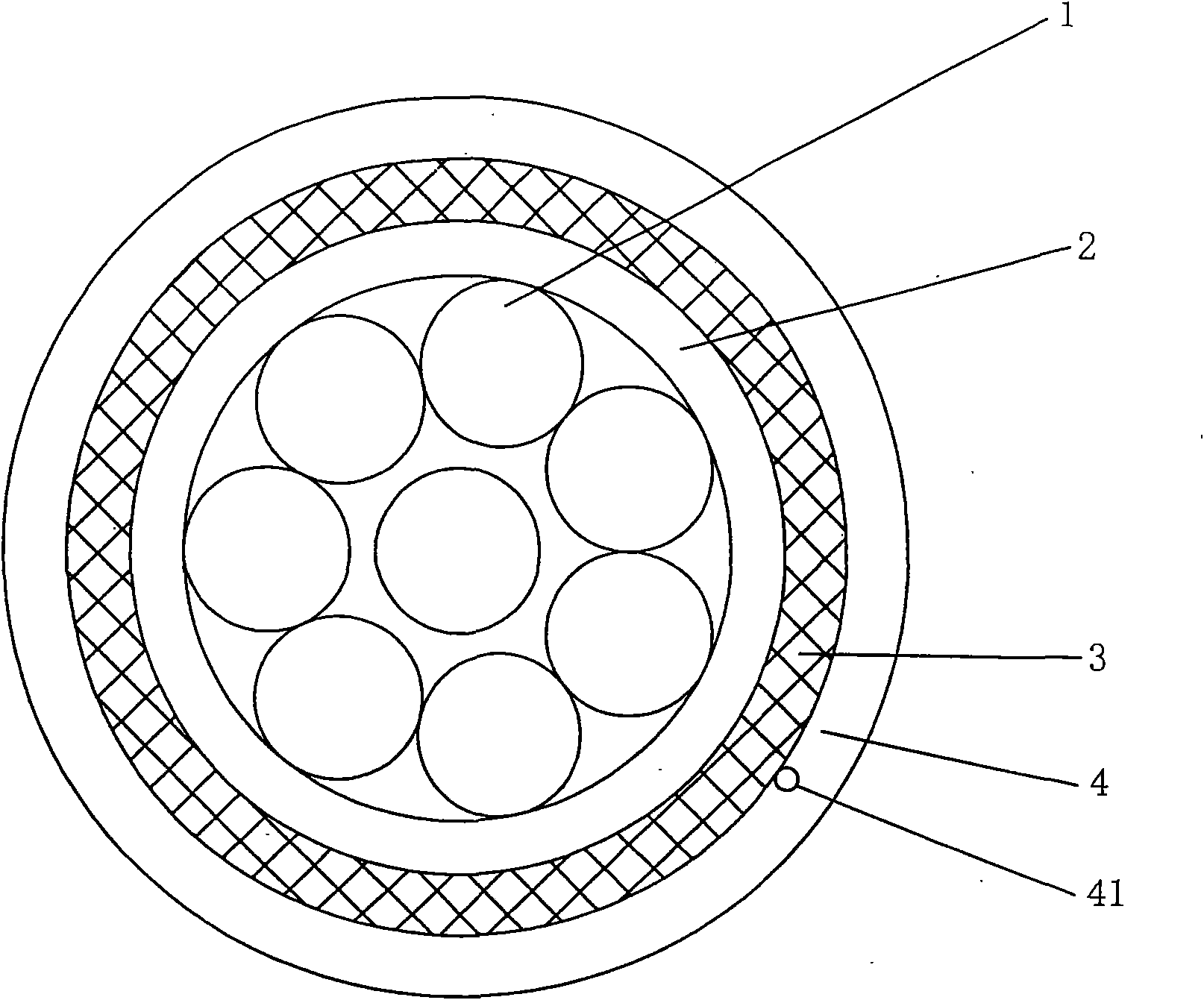

[0022] Please see figure 1 and figure 2 , see first figure 1 , a group of 8 cable cores 1 is given, and an aluminum composite tape overall shielding layer 2 is arranged outside a group of cable cores 1, and a braided overall shielding layer 3 is arranged outside the aluminum composite tape overall shielding layer 2. The braided overall shielding layer 3 is extruded and covered with a sheath layer 4 according to the usual method in the wire and cable industry, and the sheath layer 4 can also be called an outer sheath. In a preferred solution, a tear line 41 can also be designed on the sheath layer 4 to facilitate tearing during use.

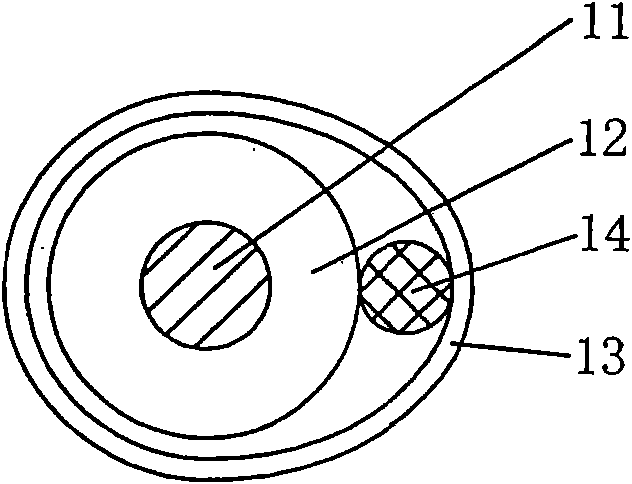

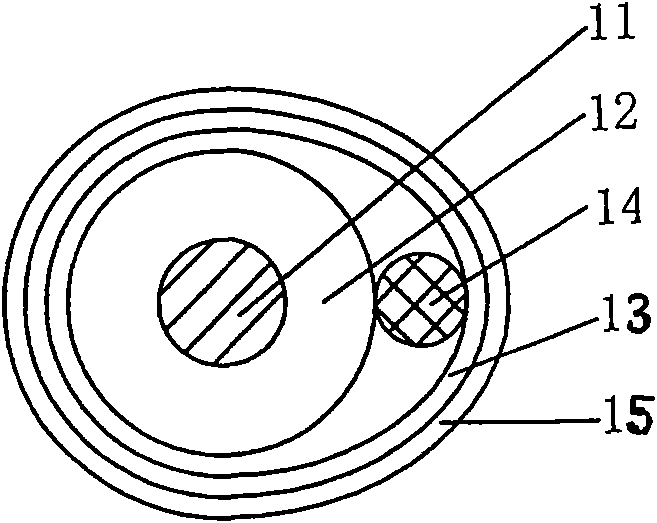

[0023] see details figure 2 ,exist figure 2 The specific structure of the aforementioned group of (8) cable cores 1 is shown in , since the structures of the 8 cable cores 1 are all the same, the applicant chooses figure 2 One of the illustrated cores 1 is detailed below. An insulating layer 12 is extruded outside a conductor 11 , and a ...

Embodiment 2

[0026] exist figure 2 The composite tape 13 of the cable core 1 of the structure shown is provided with a polyester tape layer 5 outside, and the polyester tape layer 5 can be omitted under normal circumstances, such as the structure of embodiment 1. All the other are the same as the description to embodiment 1.

[0027] As can be seen from Examples 1 and 2, the technical solution provided by the present invention saves one layer of composite tape (the prior art uses double-layer metal composite tape) and one layer located at the The outermost inner sheath of cable core 1. As a result, the overall diameter of the coaxial cable can be further reduced, which is not only beneficial to construction work, but also can save raw materials during manufacturing, so as to reflect the saving of resources. In particular, even if one layer of composite tape and inner sheath is omitted, it will not affect the performance in any way.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com