Large-specification energy-saving ceramic plate curtain wall structure and construction method thereof

A ceramic plate, large-scale technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of multiple welding processes, poor compression and impact resistance, and difficult adjustment of steel frames, so as to achieve convenient removal at any time, location Adjustable precision, save the effect of welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

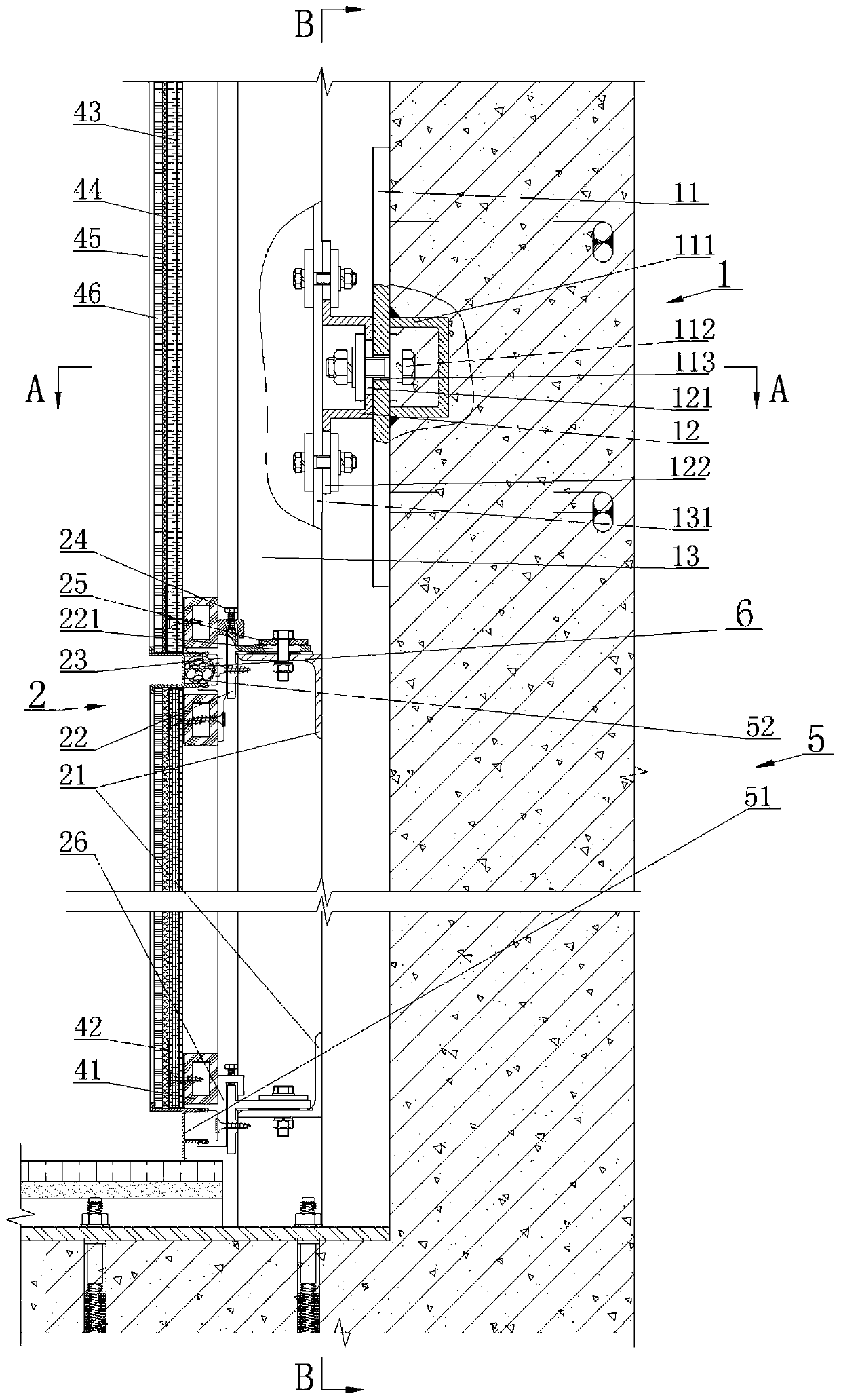

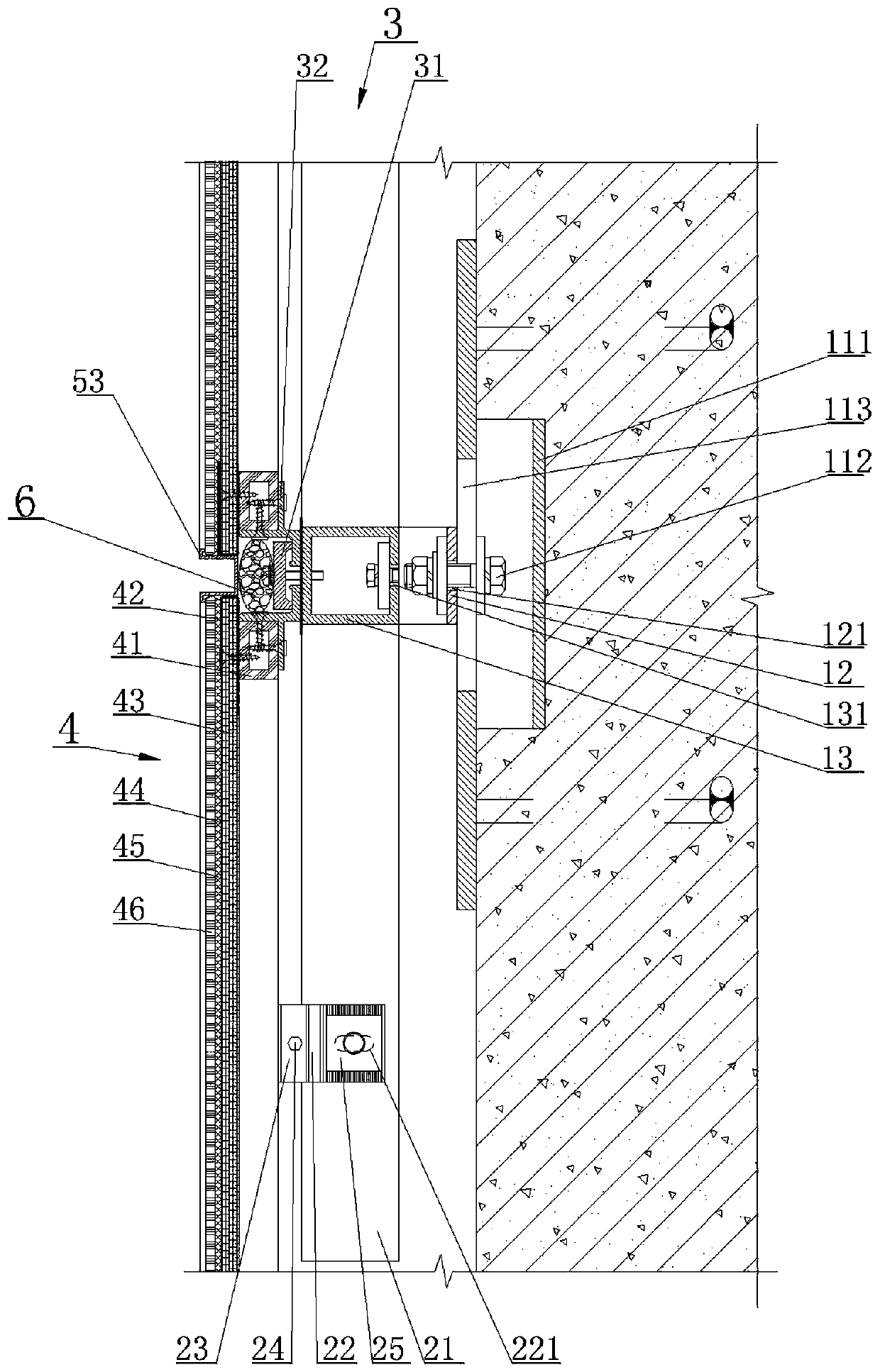

[0064] From Figure 1 to Figure 3 It can be seen that the large-scale energy-saving ceramic panel curtain wall structure of the present invention includes a steel frame component 1, a horizontal fixing component 2, a vertical fixing component 3, a ceramic composite panel component 4 and an edge closing component 5, and the steel frame component 1 is fixed In the main structure, the horizontal fixing assembly 2 and the vertical fixing assembly 3 are fixed on the steel frame assembly 1, the ceramic composite plate assembly 4 is fixed on the horizontal fixing assembly 2 and the vertical fixing assembly 3, and the edge closing assembly 5 is fixed on the ceramic Each reserved seam of the composite panel assembly 4.

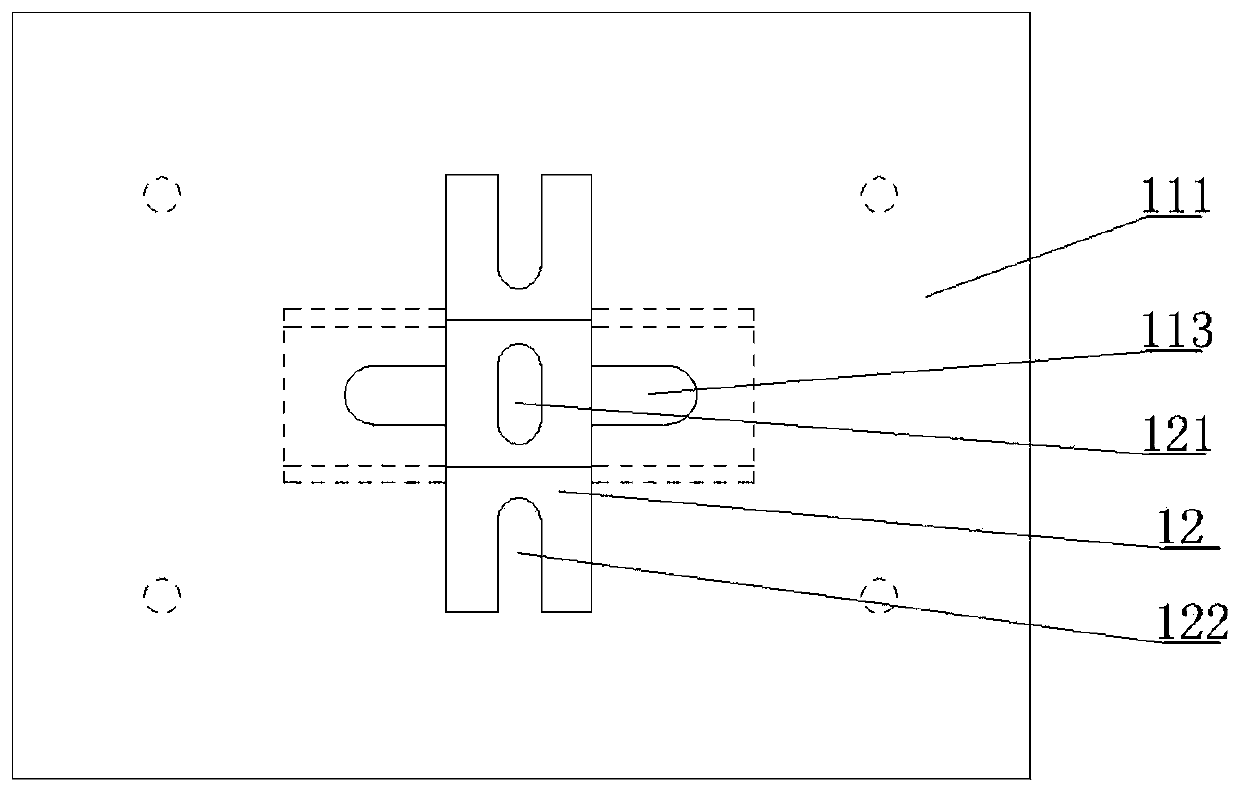

[0065] From Figure 1 to Figure 3 It can be seen that the steel frame assembly 1 of the present invention includes a notch embedded part 11, a few-shaped adapter 12 and an aluminum alloy column 13, and the notch embedded part 11 includes a pre-embedded plate 111 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com