Stationary laser scanning equipment

A laser scanning, fixed technology, applied in the direction of electromagnetic radiation induction, etc., can solve the problems of affecting work, inconvenient maintenance, wrist oppression, etc., achieve good positioning and installation, do not affect work efficiency, and reduce oppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

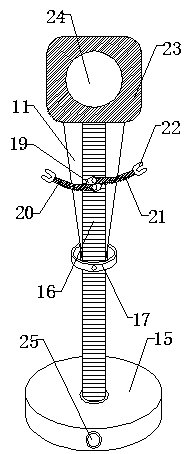

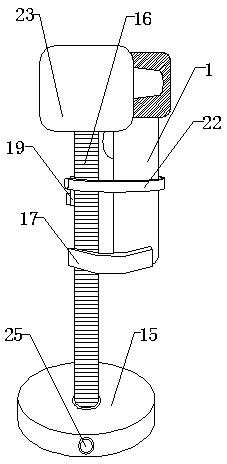

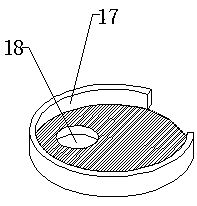

[0026] Refer to attached Figure 1-7 A fixed laser scanning device shown includes a scanner and a base, a cleaning mechanism and an up and down sliding mechanism. The scanner part includes an engine part 2 and a grip part 1, and the engine part 2 is fixed on the On the upper end of the grip part 1, five anti-skid finger rings 4 are arranged on the grip part 1, and each anti-skid finger ring 4 is a concave groove, and a scan button 3 is also arranged on the grip part 1, and the grip part 1 A circuit board is arranged inside, and an optical sensor and a control circuit are arranged on the circuit board, the optical sensor is electrically connected to the control circuit, a laser emitter and a reading lens are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com