Full-prefabricated assembly type building

A prefabricated assembly and construction technology, applied in buildings, protected buildings/shelters, building types, etc., can solve problems such as difficult quality control, no health monitoring system, cracking and leakage, and reduce garbage and environmental pollution. The construction quality is easy to control, improving the effect of thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

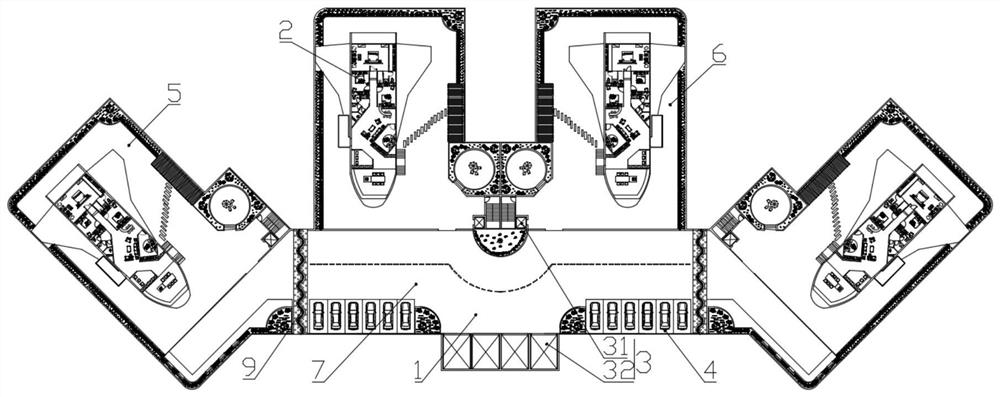

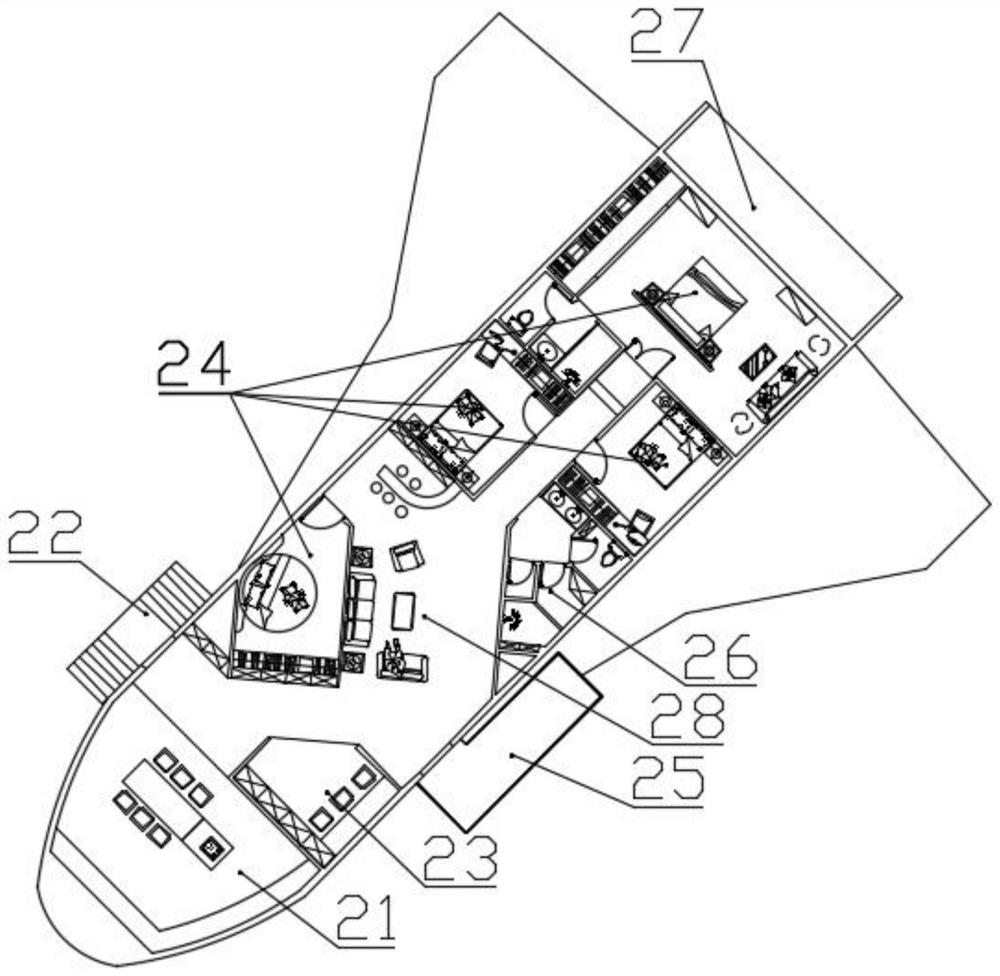

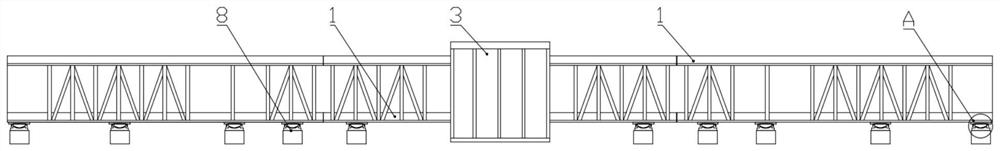

[0036] Such as Figure 1 to Figure 4 As shown: this embodiment discloses a fully prefabricated building, including a support platform 1 and a number of house bodies 2 arranged on the upper surface of the support platform 1 , and the house bodies 2 are detachably connected to the support platform 1 .

[0037] Wherein, the support platform 1 adopts a three-dimensional multi-layer structure, and the multi-layer support platforms 1 are stacked in sequence to form a multi-layer support platform 1 . Secondly, the supporting platform 1 can adopt a multi-layer prefabricated steel box girder platform. In order to ensure a wider view of the support platform 1 on each floor and make it closer to the natu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com