Prefabricated composite structure wallboard with free thermal-insulation form and manufacturing method thereof

A technology of thermal insulation and mixed structure, applied in the field of building wall panels, can solve the problems of cracking, falling off, and poor thermal insulation effect of veneer materials, and achieve the effects of improving building quality, simple construction and saving formwork

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

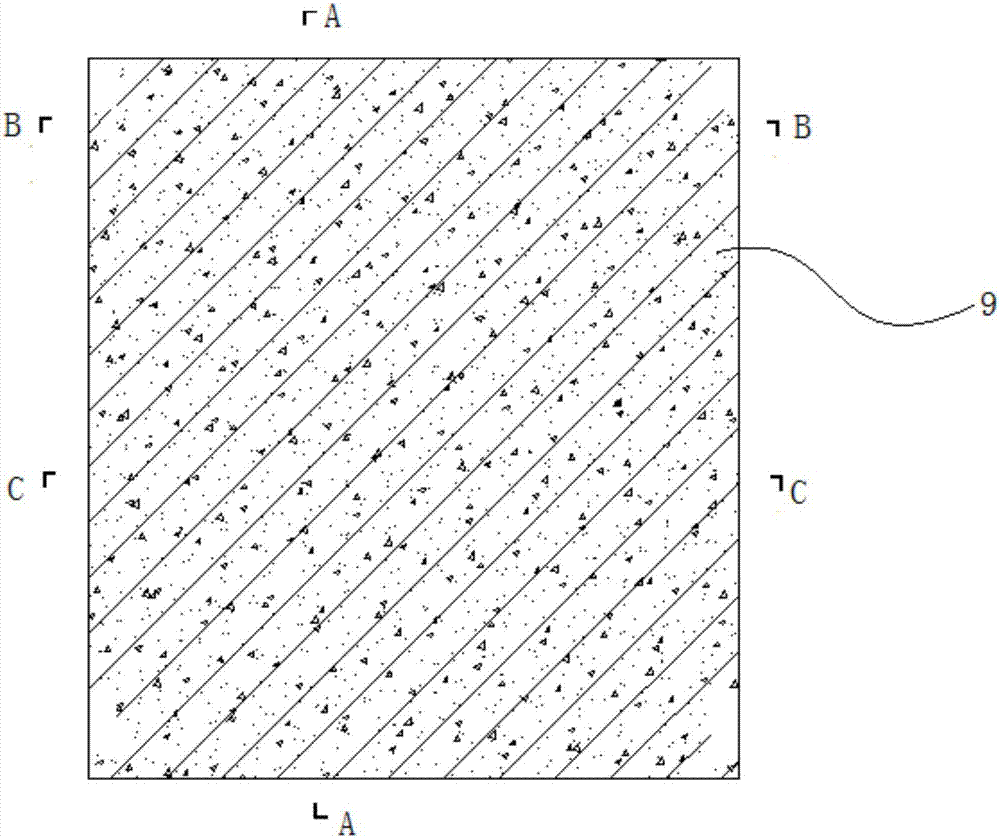

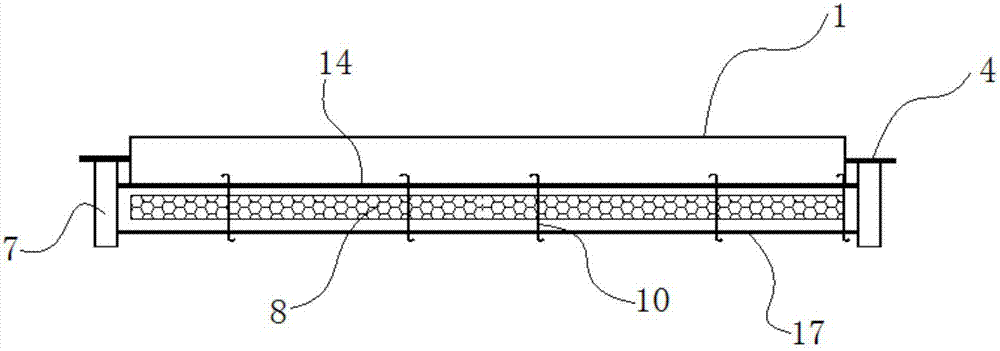

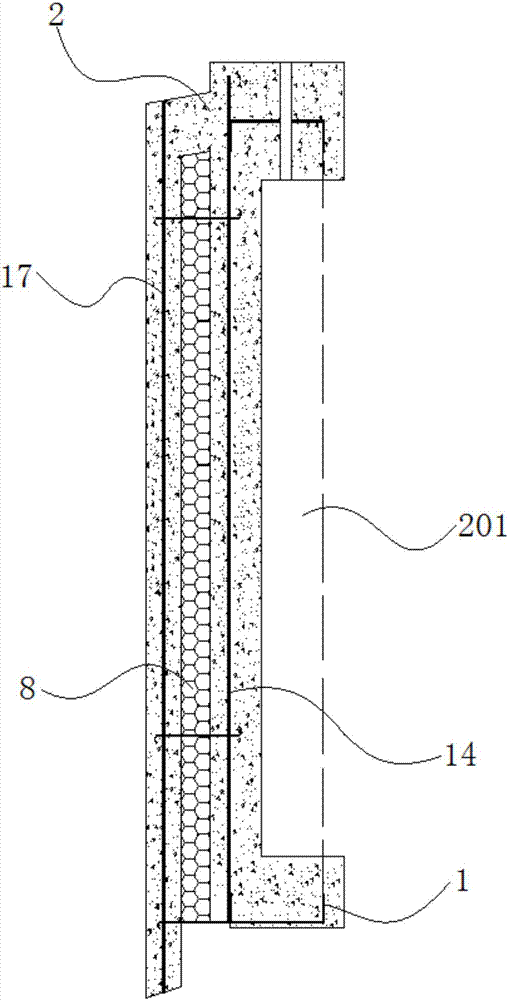

[0047] This embodiment discloses a prefabricated hybrid structure wall panel with thermal insulation free shape, including a steel skeleton 1 connected with a shear wall 11 and a beam, and concrete 2 .

[0048] see figure 2 and Figure 6 , the steel frame 1 includes two lateral bars 101 and two longitudinal bars 102 . The two side crossbars 101 and the two side longitudinal bars 102 are welded into a four-sided closed profile. The profile has an upper surface, a lower surface, an inner end surface and an outer end surface. The profiles are open on the outer and inner walls. There are two horizontal bars 103 and one longitudinal bar 104 inside the profile. The side cross bar 101, side longitudinal bar 102, cross bar 103 and longitudinal bar 104 are all hot-rolled channel steel. The side cross bar 101 , the side longitudinal bar 102 , the cross bar 103 and the longitudinal bar 1 together form a force-bearing skeleton. Two connection plates I4 are respectively welded on th...

Embodiment 2

[0055] In this embodiment, the wall body is a rectangular sheet wall body with window installation holes. see Figure 8 , The wall panels are installed between two shear walls 11 as the main body of the building structure. The free-form prefabricated composite structural wall panel with thermal insulation includes a steel skeleton 1 connected with a shear wall 11 and concrete 2 .

[0056] see Figure 9 , the steel frame 1 includes two lateral bars 101 and two longitudinal bars 102 . The two side crossbars 101 and the two side longitudinal bars 102 are welded into a four-sided closed profile. The corners of the steel frame 1 have stiffening plates II6. The profile has an upper surface, a lower surface, an inner end surface and an outer end surface. The profiles are open on the outer and inner walls. There is a horizontal bar 103 and a vertical bar 104 inside the profile. Two connection plates I4 are respectively welded on the two end faces of the steel skeleton 1 . Each...

Embodiment 3

[0062] This embodiment discloses a prefabricated free-form concrete exterior wall panel with thermal insulation. see Figure 10 , in this embodiment, the outer wall is a rectangular sheet wall with a door installation hole. The exterior wall panels are installed between two shear walls 11 that are the structural main body of the building. see Figure 11 , the steel frame 1 joins steel materials of a specified cross-section to form a designed shape by means of welding or the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com