LED (light-emitting diode) potting machine

A technology of glue filling machine and LED module, which is applied in the direction of coating and liquid coating device on the surface, etc. It can solve the problems of waterproof, electromagnetic interference, electromagnetic radiation, etc., and achieve sufficient glue filling, prevention of electromagnetic radiation, and prevention of electromagnetic radiation. interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the technical scheme of invention is described in detail:

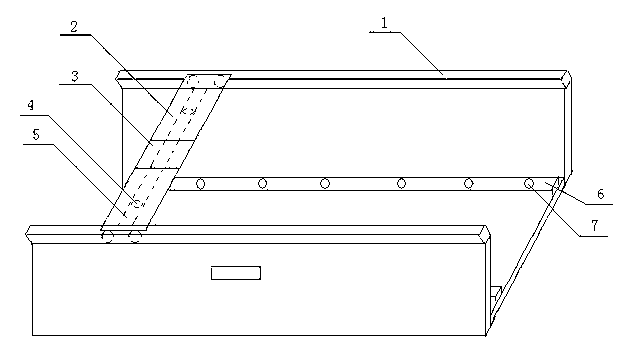

[0015] Such as figure 1 As shown, a LED glue filling machine includes a gantry frame and a LED module fixing device. The LED module fixing device includes two brackets arranged in parallel, and a plurality of connectors are arranged on the brackets. The connectors are used for For installing the LED module on the bracket, two guide rails are respectively arranged on the two frames of the gantry; the distance between the two parallel brackets is smaller than the width between the two frames of the gantry.

[0016] It also includes a traveling carriage, which is connected to the two frames of the gantry frame through a movable connection device; a guide rail is arranged on the bottom surface of the traveling carriage of the traveling carriage, and the guide rail spans between the two frames of the gantry frame; the guide rail A plurality of pulleys wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com