Electrical control system for tunnel cleaning vehicle

An electrical control system and technology for cleaning vehicles, applied in the field of electrical control systems for tunnel and subway cleaning vehicles, can solve the problems of manpower, material resources and time, inability to monitor in real time, and few control functions, and achieve a high degree of automation and complete functions. , the effect of convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is a further description in conjunction with the drawings and embodiments:

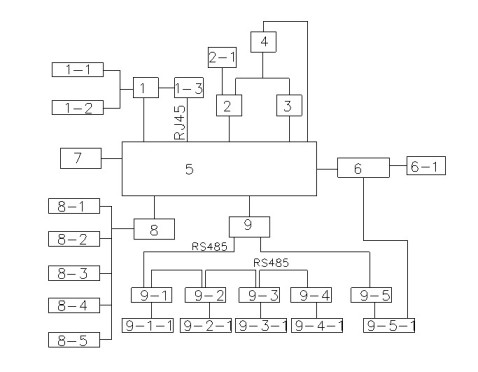

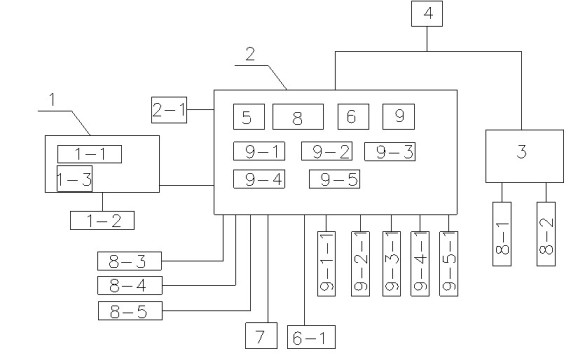

[0021] See figure 1 , The electrical control system for tunnel cleaning vehicles of the present invention includes console 1, 1# control cabinet 2, 2# control cabinet 3, DC cabinet 2-1, generator set 4, brush lifting device 7, PLC controller 5. The relay control unit 8, the hydraulic control unit 6 containing the driving brush of the hydraulic pump 9-5-1, and the driver control unit 9. Among them: the generator set 4 feeds power to 1# control cabinet 2 and 2# control cabinet 3; the 1# control cabinet 2, 2# control cabinet 3, the operation signal of the generator set 4, the signal of the console 1, and the connection To the input end of the PLC controller 5; the output end of the PLC controller 5 is respectively connected to the relay control unit 8, the driver control unit 9, the brush lifting device 7, and the hydraulic control unit 6.

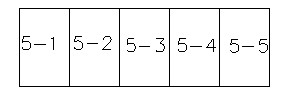

[0022] See figure 2 The PLC controller 5 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com