Integrated type drive-by-wire hydraulic braking device

A hydraulic brake, integrated technology, applied in the direction of brake transmission, brake, transportation and packaging, etc., can solve the problems of large vacuum booster, large engine dependence, complex vehicle layout, etc., to improve driving safety performance, good braking stability, and volume-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0038] In order to further illustrate the technical solution of the present invention, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

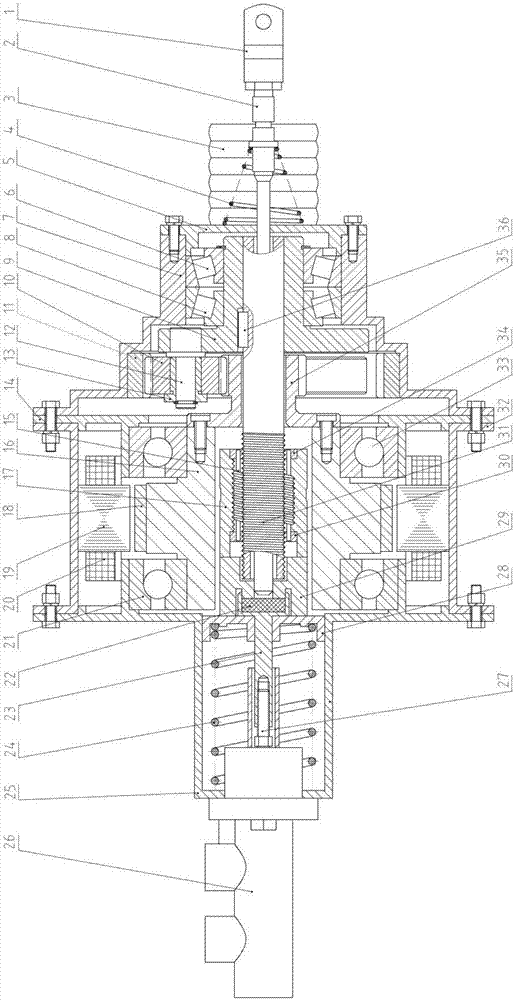

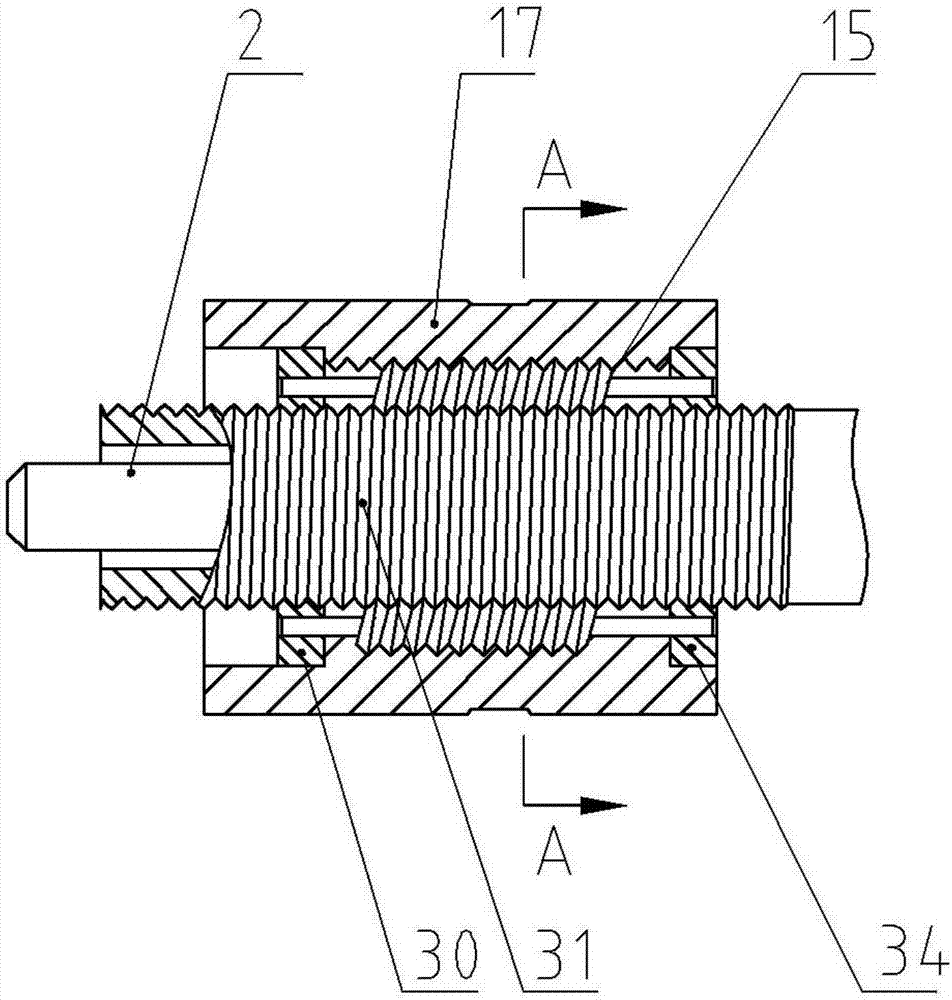

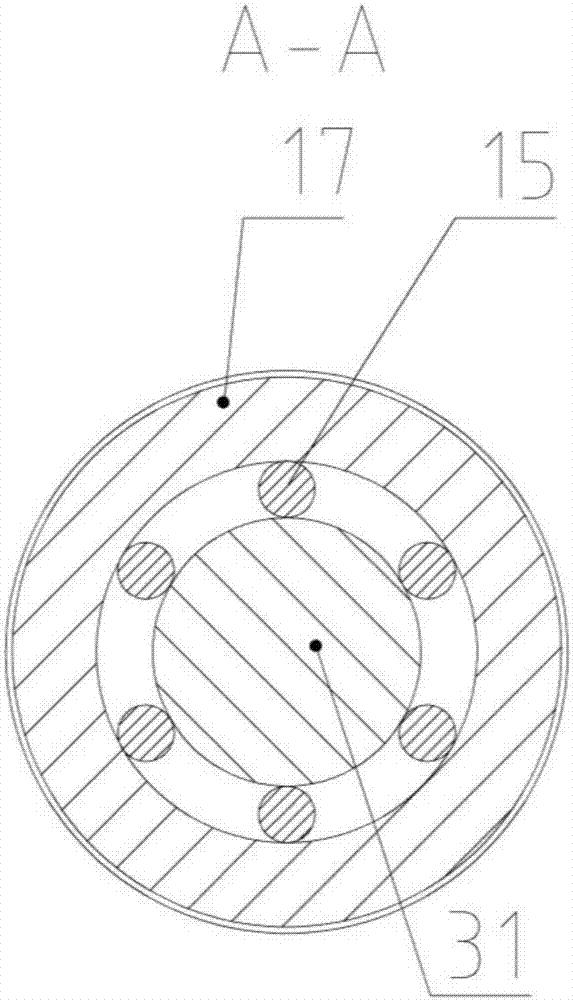

[0039] Such as figure 1 As shown, the present invention provides an integrated controlled-by-wire hydraulic brake device. The integrated controlled-by-wire hydraulic brake device is installed between the brake pedal and the brake master cylinder 26, and the brake master located at the front end It consists of a cylinder connection assembly, a motor assembly and a planetary roller screw mechanism at the middle and front end, a planetary gear mechanism at the middle and rear end, a brake pedal connection assembly at the rear end, and an end cover housing assembly.

[0040] The brake master cylinder connection assembly includes: rubber feedback disc 22, output push rod 23, return spring 24, master cylinder push rod 27, spring seat 28 and stroke adjustment base 29;

[0041] The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com