Energy-efficient hydraulic power supply driven by permanent magnet servo motor

A permanent magnet servo motor and hydraulic power source technology, applied in the field of hydraulic equipment manufacturing, can solve the problems of large proportion of excitation current, poor anti-pollution ability, poor low-speed characteristics of asynchronous motors, etc., and achieve large overload multiples and fast response Fast, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

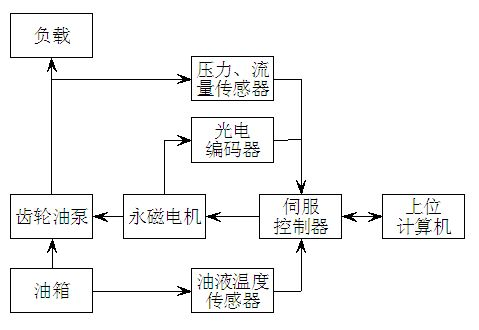

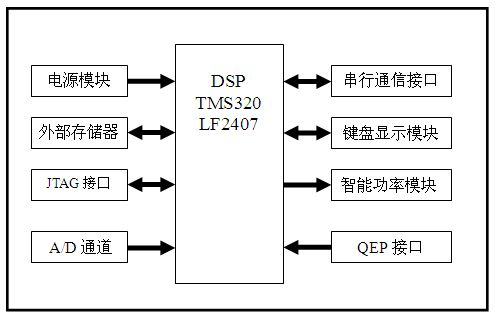

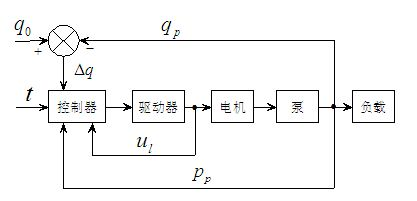

[0031] like figure 1 As shown, the energy-saving hydraulic power source driven by the permanent magnet servo motor of the present invention includes a gear oil pump, a three-phase AC permanent magnet synchronous motor, a servo controller, a flow sensor, a pressure sensor, an oil temperature sensor, a photoelectric encoder and a fuel tank , load and host computer. Among them, the servo controller is the core of the whole control system, and its parameter setting and operating status parameter monitoring can be conveniently carried out through the host computer. The photoelectric encoder, three-phase AC permanent magnet synchronous motor and servo controller form a closed-loop AC servo system, in which the photoelectric encoder is used to measure the speed and position of the three-phase AC permanent magnet synchronous motor rotor, and the servo controller outputs PWM through the event manager EVA The signal drives the three-phase AC permanent magnet synchronous motor to rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com