Preparation method of high-throughput anti-pollution composite nanofiltration membrane

A composite nanofiltration membrane and anti-pollution technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as poor long-term use effect and unsatisfactory anti-pollution ability, and achieve good industrial applicability , Improve flux and anti-pollution ability, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

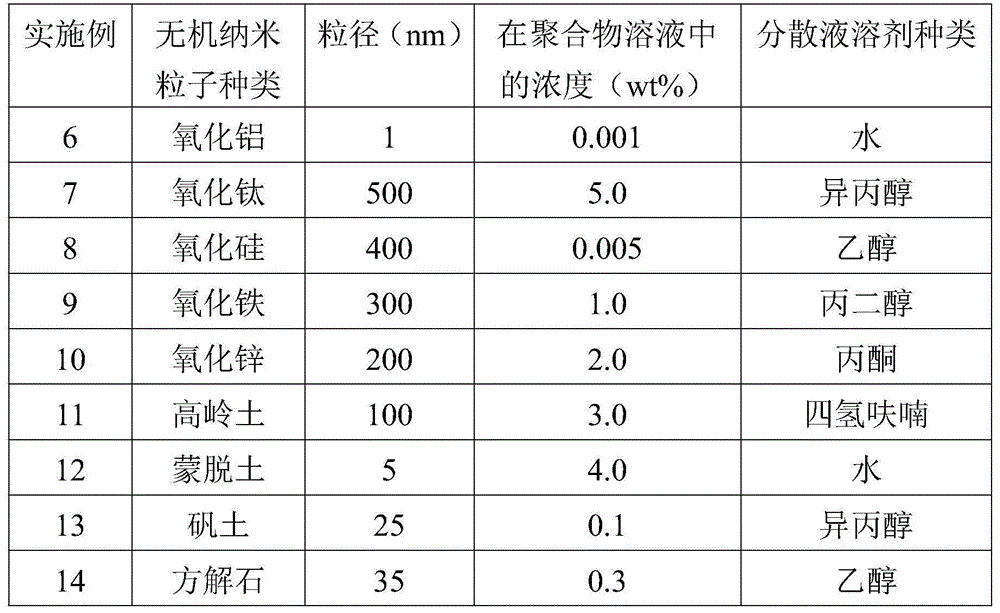

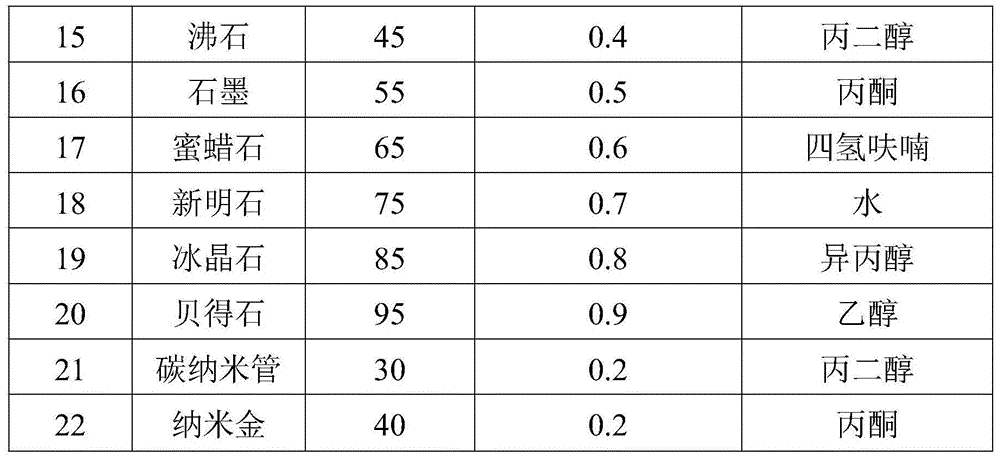

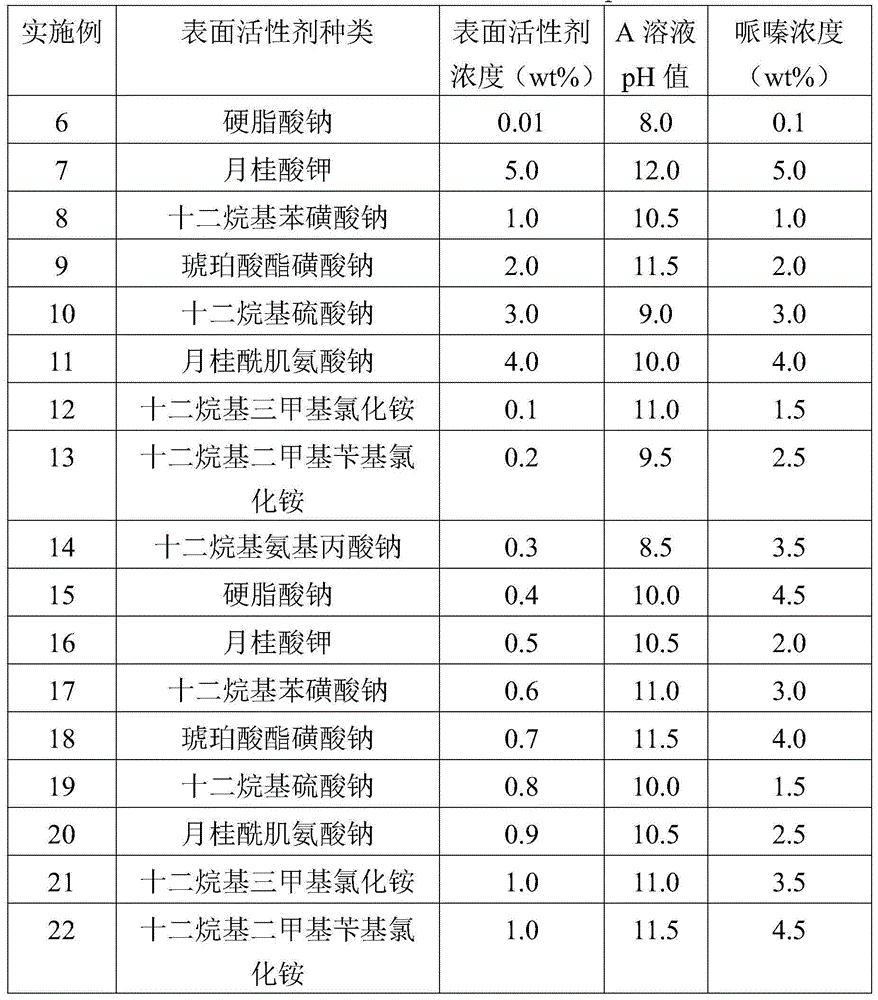

Examples

Embodiment 1

[0030] (1) Preparation of polymer solution: Prepare 0.05wt% nano-titanium dioxide dispersion (the solid content of the dispersion is 20%, the solvent is water, and the particle size is 15nm) and evenly disperse it in the polysulfone polymer solution, stirring at high speed for 1.25h, Then add the polymer and continue to stir for 8 hours, the temperature of the polymer solution is controlled at 90°C; after the preparation of the polymer solution is completed, high-temperature defoaming is carried out, and the temperature is lowered to 25°C;

[0031] (2) Preparation of a porous polymer support layer: the polymer solution in step (1) is prepared by a liquid-solid phase conversion method to prepare a porous polymer support layer;

[0032] (3) Prepare A solution: Prepare 2.0wt% piperazine and 0.005wt% sodium dodecylbenzenesulfonate and dissolve them uniformly in pure water, and add an appropriate amount of NaOH to adjust the pH value to 11 to prepare A solution;

[0033] (4) Prepar...

Embodiment 2

[0036] (1) Preparation of polymer solution: Prepare 0.05wt% nano-titanium dioxide dispersion (the solid content of the dispersion is 20%, the solvent is isopropanol, and the particle size is 50nm) and evenly disperse it in the polysulfone polymer solvent, stirring at a high speed for 1.25 h, then add the polymer and continue to stir for 8 hours, the temperature of the polymer solution is controlled at 90°C; after the preparation of the polymer solution is completed, high-temperature defoaming is performed, and the temperature is lowered to 25°C;

[0037] (2) Preparation of a porous polymer support layer: the polymer solution in step (1) is prepared by a liquid-solid phase conversion method to prepare a porous polymer support layer;

[0038] (3) Prepare A solution: prepare 2.0wt% piperazine and 0.01wt% sodium dodecylbenzenesulfonate and dissolve them in pure water evenly, and add an appropriate amount of NaOH to adjust the pH value to 11 to prepare A solution;

[0039] (4) Prep...

Embodiment 3

[0042] (1) Preparation of polymer solution: Prepare 0.20wt% nano-silica dispersion (the solid content of the dispersion is 20%, the solvent is isopropanol, and the particle size is 20nm) and evenly disperse it in the polyimide polymer solution , stirred at high speed for 1.25 hours, then added the polymer and continued to stir for 8 hours, the temperature of the polymer solution was controlled at 90°C; after the polymer solution was prepared, high-temperature defoaming was carried out, and the temperature was lowered to 25°C;

[0043] (2) Preparation of a porous polymer support layer: the polymer solution in step (1) is prepared by a liquid-solid phase conversion method to prepare a porous polymer support layer;

[0044] (3) Prepare A solution: Prepare 2.0wt% piperazine and 0.005wt% sodium lauryl sulfate and dissolve them in pure water evenly, and add an appropriate amount of NaOH to adjust the pH value to 11, that is, A solution is prepared;

[0045] (4) Prepare B solution: p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com