Preparation method of anti-pollution composite nanofiltration membrane

A composite nanofiltration membrane, anti-pollution technology, applied in the field of nanofiltration, can solve the problems of affecting the degree of crosslinking of the polyamide layer of the composite membrane, reducing the surface charge of the functional layer, weak binding force of the polyamide layer, etc., to achieve excellent anti-pollution. performance, reduced salt bridge effect, uniform distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

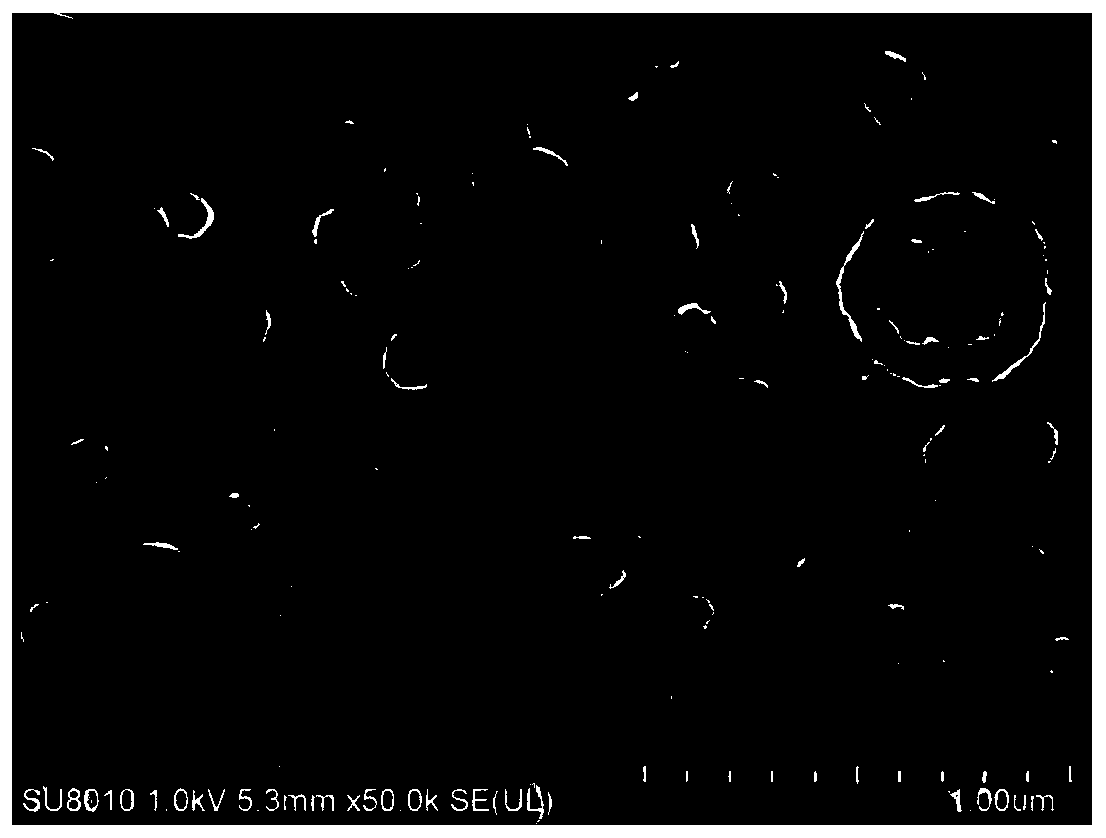

Image

Examples

Embodiment 1

[0035] (1) The polysulfone ultrafiltration membrane supported by non-woven fabric is fixed with a polytetrafluoroethylene plate frame, and the prepared first aqueous phase solution containing 1.0 wt% piperazine and 2.0 wt% trisodium phosphate is poured on the ultrafiltration For the surface of the membrane, the immersion time is 2 min. After pouring off the aqueous phase solution, roll it with a rubber roller to remove the residual solution on the surface of the ultrafiltration membrane;

[0036] (2) pour the prepared Isopar L oil phase solution containing 0.2wt% trimesoyl chloride on the surface of the ultrafiltration membrane and carry out an interfacial polymerization reaction, the reaction time is 40s, do not do any heat treatment after pouring off the oil phase solution, Use air knife or air knife to blow evenly until there is no residual solvent on the membrane surface;

[0037](3) The second aqueous phase solution containing 0.03wt% piperazine and 0.5wt% mass fraction o...

Embodiment 2

[0039] The main difference between this example and Example 1 is that the mass fraction of polyethylene glycol in the second aqueous phase solution in the step (3) is 1.0wt%.

Embodiment 3

[0041] The main difference between this example and Example 1 is that the mass fraction of polyethylene glycol in the second aqueous phase solution in the step (3) is 1.5wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com