Hydrophobic film with self-cleaning function, preparation method thereof and application thereof

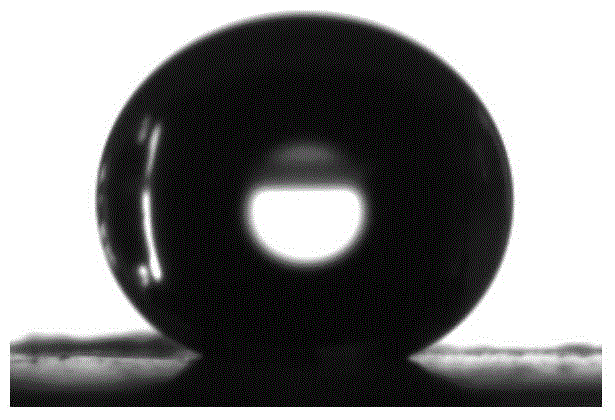

A hydrophobic membrane, self-cleaning technology, applied in spinning solution preparation, chemical instruments and methods, membrane technology, etc., can solve the problems of hydrophobic damage of membrane surface or membrane pores, membrane surface pollution, decreased service life, etc. The size and distribution are controllable, the effect of reducing the cost of membrane use and prolonging the service life of the membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

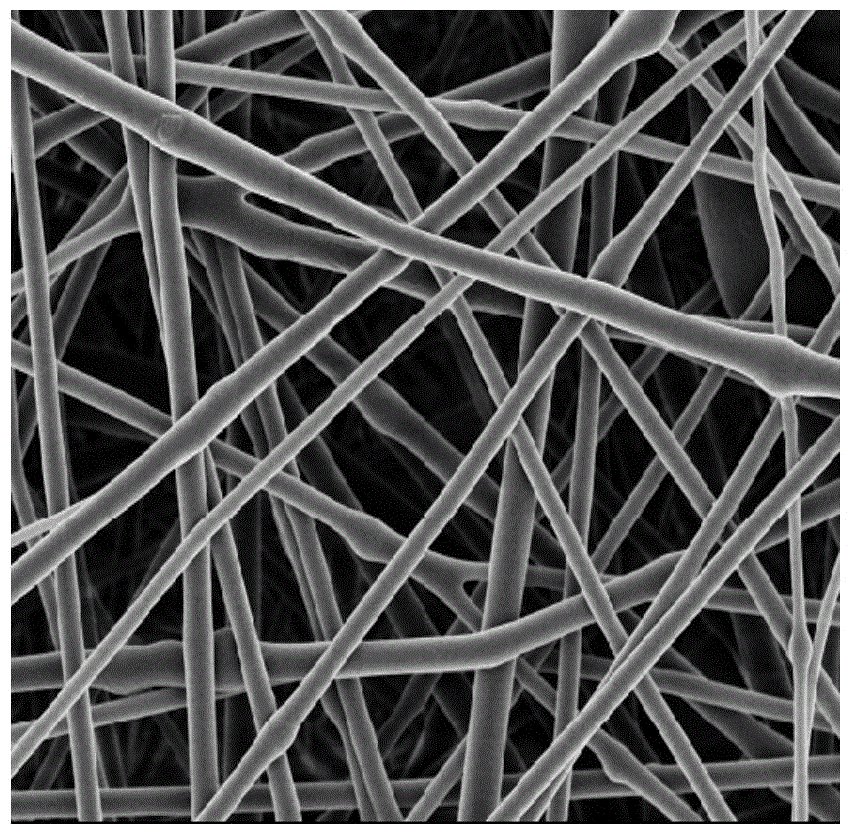

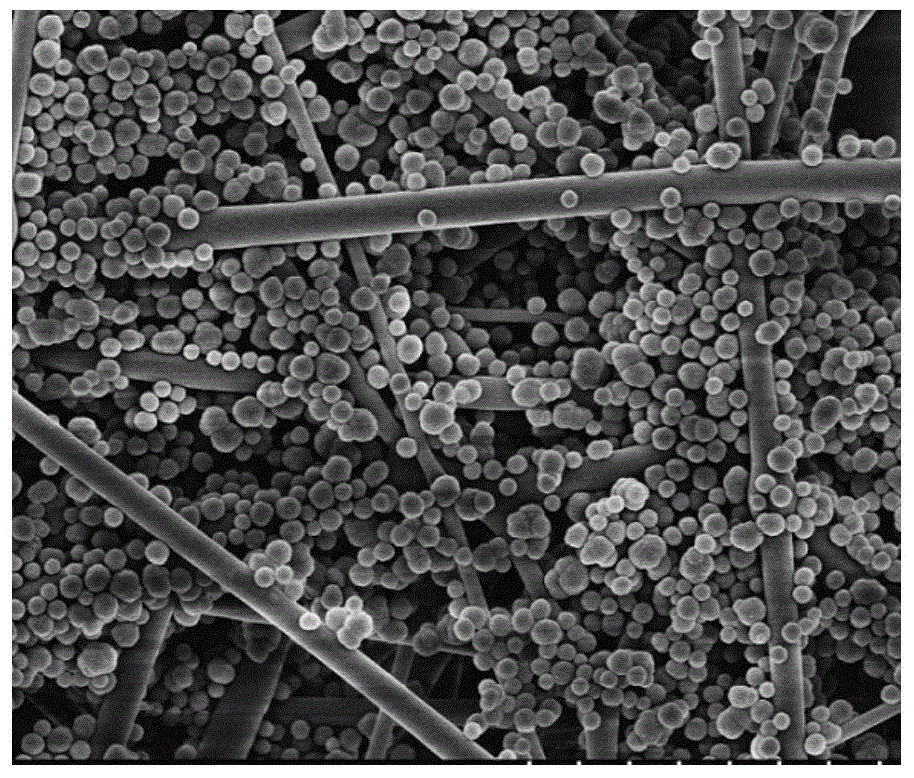

[0029] Weigh 1g of PE particles and dissolve them in 3mL of TFA with stirring, stir magnetically for 3 hours until all PE particles are dissolved, and let stand for 12 hours for defoaming. The above defoamed solution was electrospun at a temperature of 15°C and a relative humidity of 10%. The spinning parameters were as follows: the flow rate of the syringe pump was 1.0 mL, the flow rate was 0.5 mL / h, and the distance between the needle and the receiver was It is 8cm, the voltage is 20kv, and it is ready for use after spinning. The nano-silica sol was prepared by a sol-gel method, and the particle size was 50nm. Soak the obtained PE nanofiber membrane in the nano-sol for 1 min, take it out to dry, and soak once. Obtain the desired self-cleaning film. Example 2:

Embodiment 2

[0030]Weigh 1.5g of PE particles and dissolve them in 3mL of TFA under stirring, stir magnetically for 3.5 hours until all PE particles are dissolved, and let stand for 14 hours for defoaming. The above defoamed solution was electrospun at a temperature of 25°C and a relative humidity of 21%. The spinning parameters were as follows: the flow rate of the syringe pump was 1.0 mL, the flow rate was 0.5 mL / h, and the distance between the needle and the receiver was It is 9cm, the voltage is 20kv, and it is ready for use after spinning. The nano-alumina sol was prepared by a sol-gel method, and the particle size was 15nm. Soak the obtained PE nanofiber membrane in the nanosol for 1 min, take it out to dry, and soak twice. Obtain the desired self-cleaning film. After testing, the contact angle value of the obtained self-cleaning film to water is 144°.

Embodiment 3

[0032] Weigh 1 g of PET particles and dissolve them in 3 mL of DMF under stirring, stir magnetically for 4 hours until all PET particles are dissolved, and let stand for 14 hours for defoaming. The above defoamed solution was electrospun at a temperature of 25°C and a relative humidity of 30%. The spinning parameters were as follows: the flow rate of the syringe pump was 1.0 mL, the flow rate was 0.5 mL / h, and the distance between the needle and the receiver was It is 10cm, the voltage is 20kv, and it is ready for use after spinning. The nano-silica sol is prepared by a sol-gel method, and the particle size is 100 nm. Soak the obtained PET nanofiber membrane in the nano-sol for 1 min, take it out to dry, and soak for 3 times. Obtain the desired self-cleaning film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com