Method of preparing antibacterial anti-pollution ultrafiltration membrane by adopting silver-loaded nano composite material

A nanocomposite material and nanomaterial technology are applied in the field of preparing antibacterial and antifouling ultrafiltration membranes, which can solve the problems of loss of antibacterial and antifouling properties of modified ultrafiltration membranes, lack of long-term stability of silver nanoparticles, secondary pollution of material and liquid, etc. , to achieve long-term stable antibacterial and anti-pollution ability, excellent anti-pollution performance, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Prepare 50 mL of an aqueous dispersion containing 0.1 g of polyaniline nanofibers, add 0.09 g of tris and 0.1 g of dopamine hydrochloride, stir and react for 8 hours, centrifuge, wash and then dry to obtain polydopamine-modified nanomaterials. Then, 50 mL of aqueous dispersion containing 0.1 g of polydopamine-modified nanomaterials was prepared, 0.25 g of silver nitrate and 0.25 g of polyvinylpyrrolidone were added, stirred for 2 hours, washed by centrifugation and dried to obtain silver-loaded nanocomposites.

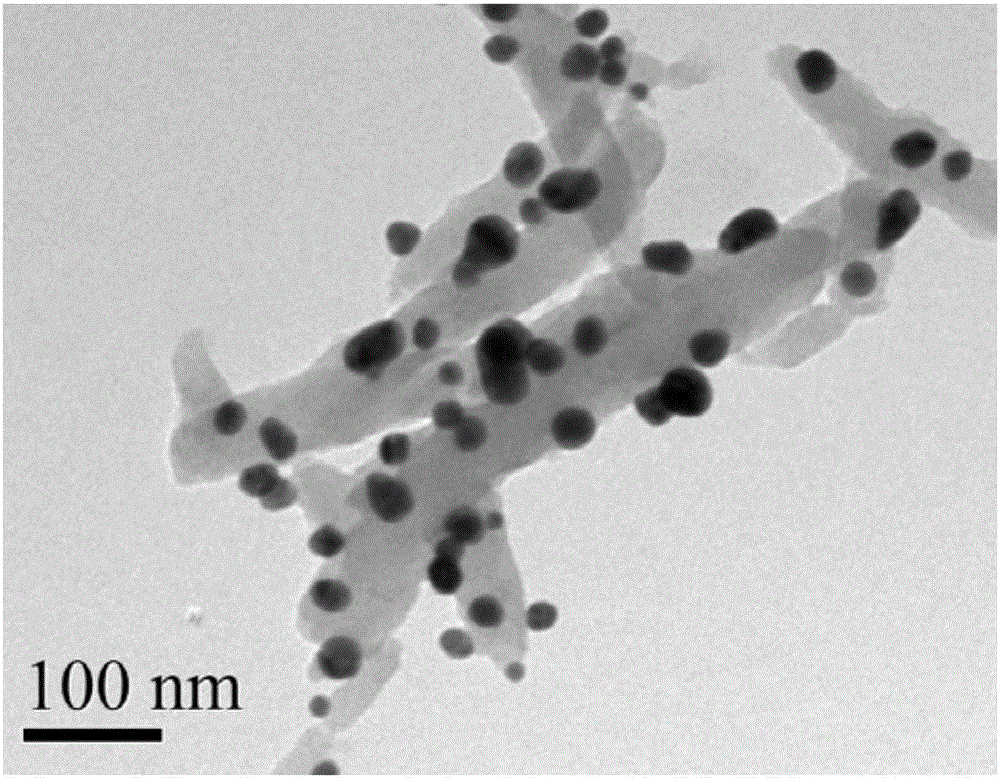

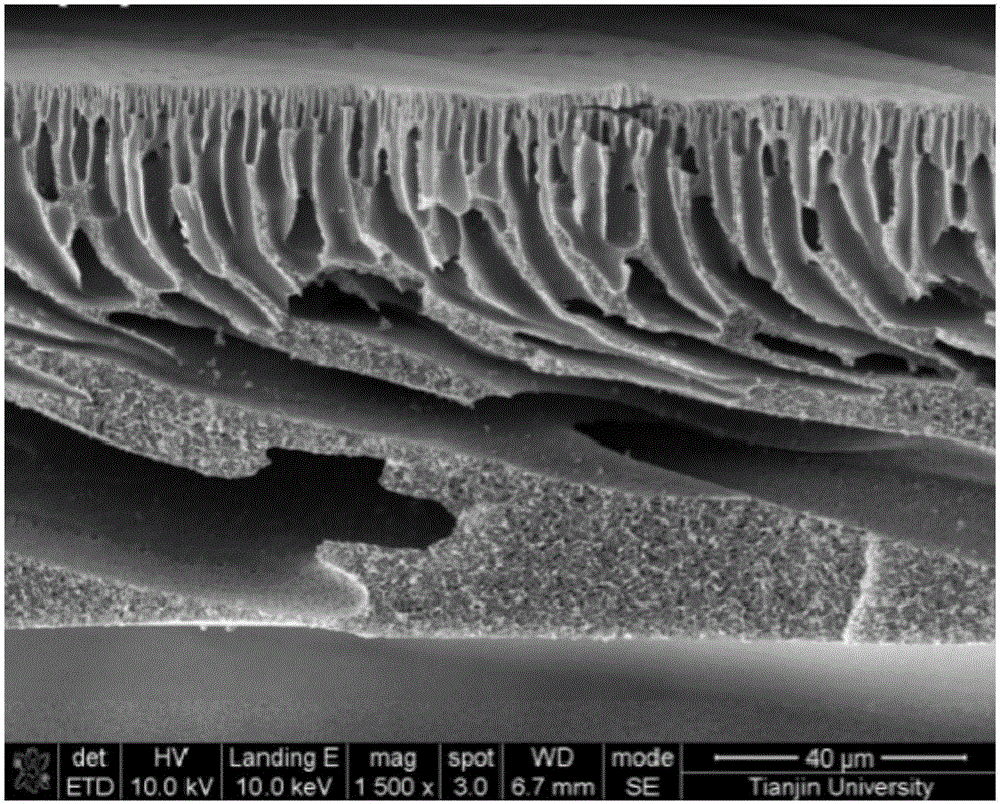

[0025] (2) Take 0.1g of silver-loaded nanocomposite and disperse it in 16.9g of dimethylacetamide, then add 3.0g of polysulfone, stir until it is completely dissolved, then let it stand to obtain a casting solution, and use a scraper to remove the casting solution Coating a film on a glass plate, immersing in water after pre-evaporating, and obtaining an ultrafiltration membrane containing silver-loaded nanocomposite material. The transmission electron micro...

Embodiment 2

[0028] (1) Prepare 50 mL of an aqueous dispersion containing 0.025 g of graphene nanosheets, add 0.09 g of tris and 0.05 g of dopamine hydrochloride, stir and react for 12 hours, and dry after centrifugal washing to obtain polydopamine-modified nanomaterials. Then, 50 mL of an aqueous dispersion containing 0.025 g of polydopamine-modified nanomaterials was prepared, 0.025 g of silver nitrate and 0.1 g of polyether were added, stirred for 12 hours, washed by centrifugation and then dried to obtain silver-loaded nanocomposites.

[0029] (2) Take 0.02g of silver-loaded nanocomposite and disperse it in 15.98g of dimethylacetamide, then add 4.0g of polyethersulfone, stir until it is completely dissolved, then let it stand to obtain the casting solution, and use a scraper to remove the casting solution The machine coats the film on the glass plate, immerses in water after pre-evaporation, and obtains the ultrafiltration membrane containing the silver-loaded nanocomposite material.

...

Embodiment 3

[0032] (1) Prepare 50 mL of an aqueous dispersion containing 0.25 g of carbon nanotubes, add 0.09 g of tris and 0.1 g of dopamine hydrochloride, stir and react for 5 hours, centrifuge, wash and dry to obtain polydopamine-modified nanomaterials. Then, 50 mL of an aqueous dispersion containing 0.25 g of polydopamine-modified nanomaterials was prepared, 0.1 g of silver nitrate and 0.025 g of polyethylene glycol were added, stirred for 12 hours, centrifuged, washed, and then dried to obtain silver-loaded nanocomposites.

[0033] (2) Take 0.2g of silver-loaded nanocomposite and disperse it in 8.0g of dimethylformamide, then add 1.8g of polysulfone, stir until it is completely dissolved, then let it stand to obtain a casting solution, and use a scraper to remove the casting solution Coating a film on a glass plate, immersing in a 10:1 mixture of water and dimethylformamide after pre-evaporation, to obtain an ultrafiltration membrane containing a silver-loaded nanocomposite material. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com