PES ultra-filtration film loaded with Ag-TiO2 and preparation method and application of PES ultra-filtration film

An ultrafiltration membrane, surface loading technology, applied in ultrafiltration, chemical instruments and methods, membranes, etc., can solve the problems of reducing membrane treatment performance, limiting the application of membrane separation technology, low chemical energy consumption, etc., to achieve enhanced anti-pollution performance. , effective separation, low chemical energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

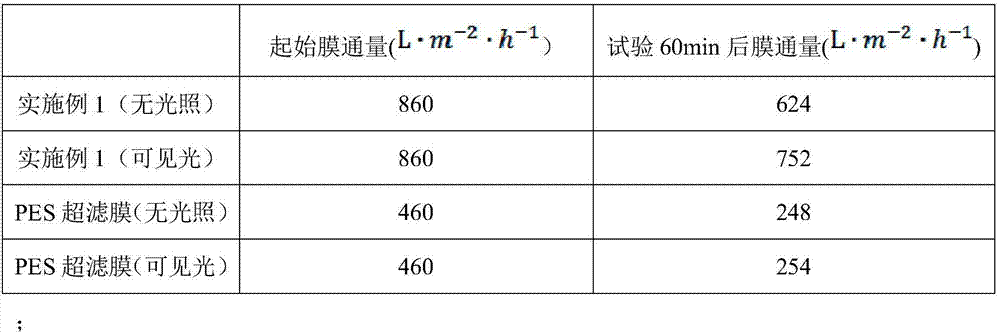

Embodiment 1

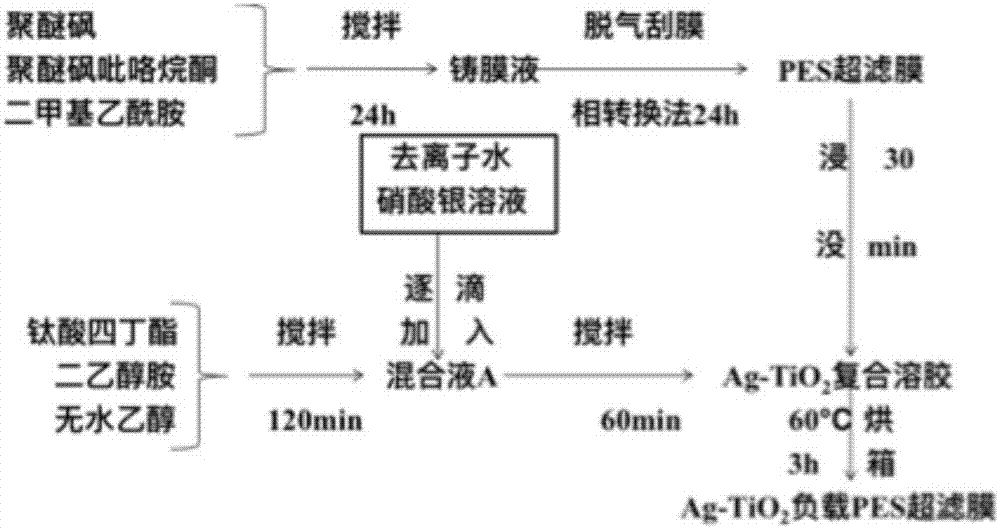

[0026] The present invention is loaded with Ag-TiO 2 The preparation method of the PES ultrafiltration membrane specifically comprises the steps:

[0027] Step 1, prepare PES ultrafiltration membrane: add 8g polyethersulfone and 1g polyvinylpyrrolidone into 43.5mL dimethylacetamide solvent, seal and stir at room temperature for 24h to obtain casting solution; place casting solution at room temperature Degas for 6 hours, then pour about 15mL of casting solution on the glass plate, scrape the film on the glass plate at a constant speed of 0.5cm / s with a scraper knife; put the glass plate coated with casting solution flat into the deionized The phase conversion is carried out in water, and the PES ultrafiltration membrane is obtained after 24 hours;

[0028] Step 2: Preparation of Ag-TiO 2 Composite sol: Mix 23.5mL tetrabutyl titanate, 4.8mL diethanolamine and 67.3mL absolute ethanol, stir at room temperature for 120min to obtain mixed solution A; mix 10mL deionized water and 1...

Embodiment 2

[0031] The present invention is loaded with Ag-TiO 2 The preparation method of the PES ultrafiltration membrane specifically comprises the steps:

[0032] Step 1, prepare PES ultrafiltration membrane: add 8g polyethersulfone and 1g polyvinylpyrrolidone into 43.5mL dimethylacetamide solvent, seal and stir at room temperature for 24h to obtain casting solution; place casting solution at room temperature Degas for 6 hours, then pour about 15mL of casting solution on the glass plate, scrape the film on the glass plate at a constant speed of 0.5cm / s with a scraper knife; put the glass plate coated with casting solution flat into the deionized The phase conversion is carried out in water, and the PES ultrafiltration membrane is obtained after 24 hours;

[0033] Step 2: Preparation of Ag-TiO 2 Composite sol: Mix 23.5mL tetrabutyl titanate, 4.8mL diethanolamine and 67.3mL absolute ethanol, stir at room temperature for 120min to obtain mixed solution A; mix 10mL deionized water and 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com