Film assembly cleaned mechanically

A technology for mechanical cleaning and membrane modules, applied in membrane technology, semi-permeable membrane separation, biological water/sewage treatment, etc., can solve the problems of increasing water permeation, reducing energy consumption, reducing the degree of membrane fouling, etc., and improving membrane flux. , reduce thickness, make simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

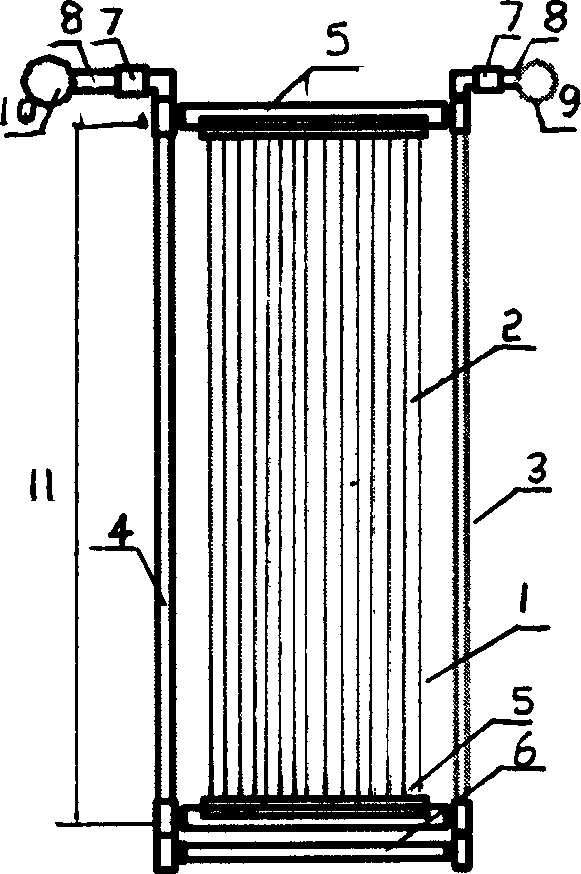

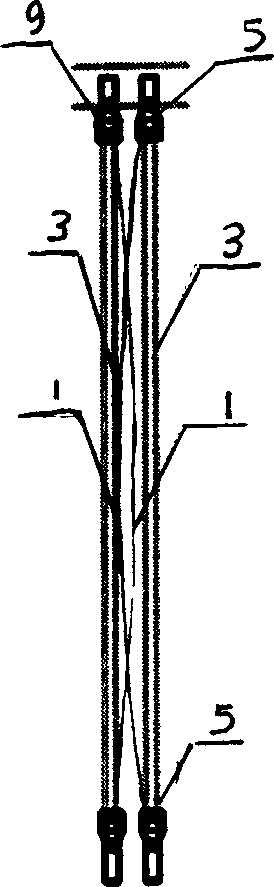

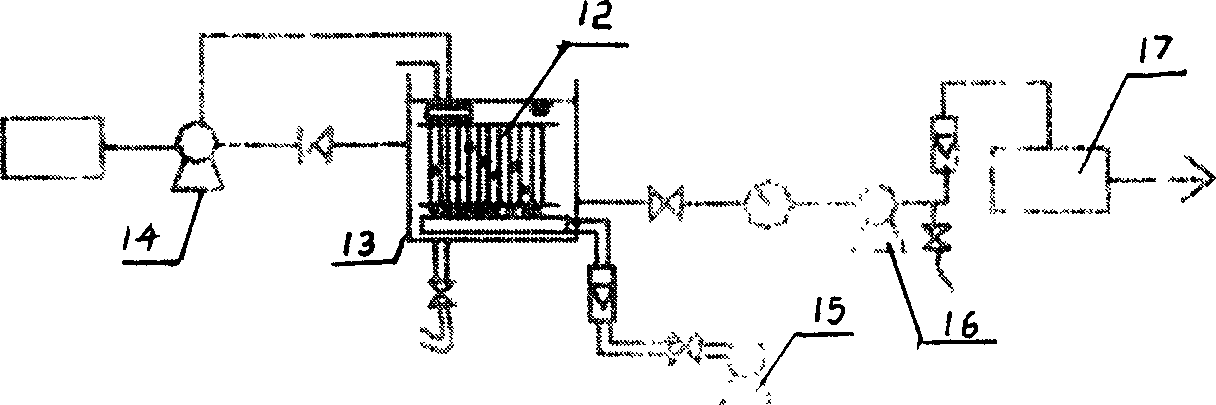

[0027] See figure 1 and figure 2 . The membrane module 12 includes a membrane, a water outlet branch pipe and an aeration pipe. The placement of the two diaphragms 11 is based on ensuring that the membrane filaments 1 of each diaphragm 11 can collide with each other to generate friction, and the membrane filaments are hollow fiber ultrafiltration membranes. The membrane filament 1 and the membrane brush 2 have a certain radian to ensure that the membrane filament 1 and the membrane brush 2 can vibrate and move when inflated, and the membrane brush is nylon with a smooth surface. Membrane brushes 2 are placed parallel to each other at intervals between membrane filaments 1, and membrane filaments 1 and membrane brushes 2 move relative to each other to generate friction when inflated. The two ends of the membrane filament 1 are respectively connected to the upper and lower water collection pipes 5 , the outlet water passes through the membrane filament 1 and collects in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com