Method for testing high-combination performance coating strength based on pressure experimental device and its sample

A pressure test and combined performance technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve problems such as large errors and unreasonable sample structures, and achieve uniform force, simple and clear physical meaning, and convenient clamping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

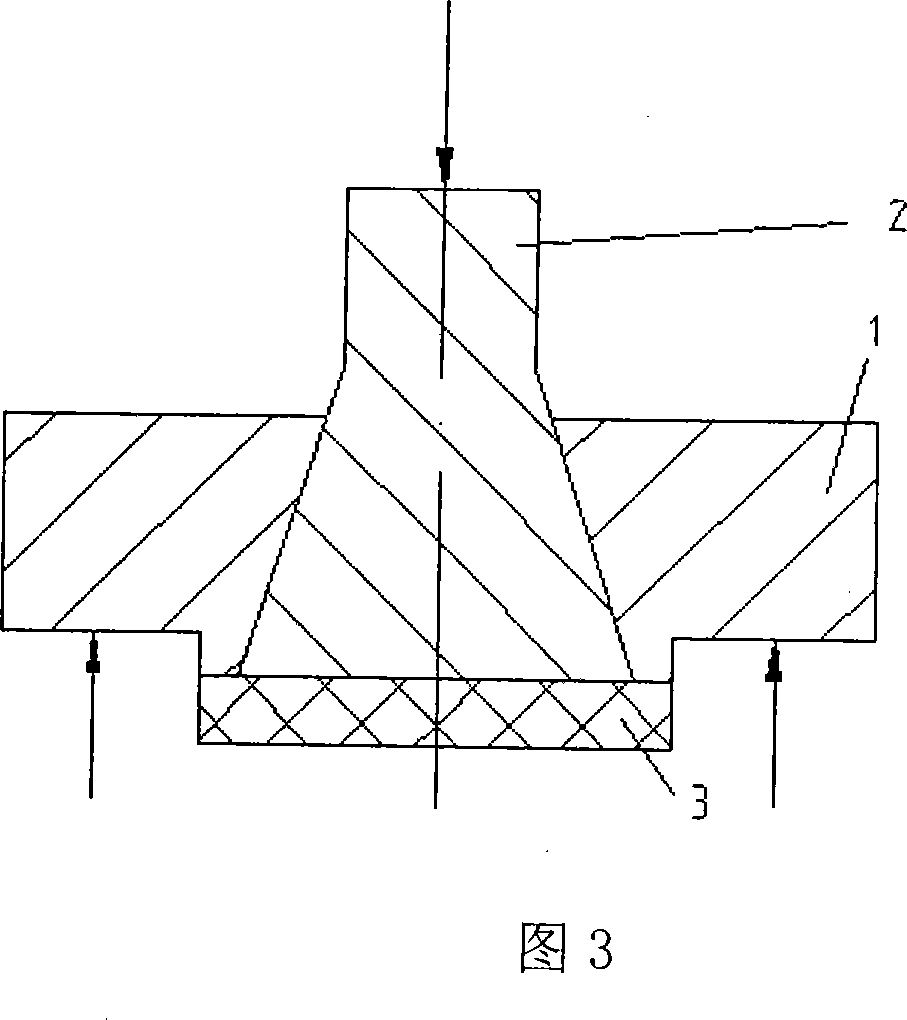

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0030] As shown in Figure 3.

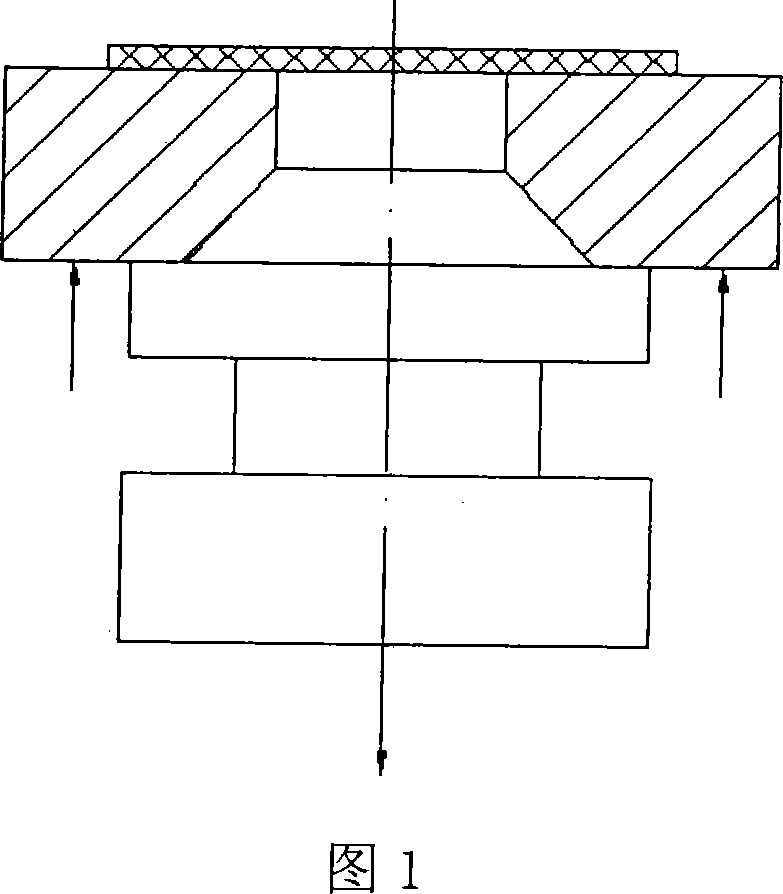

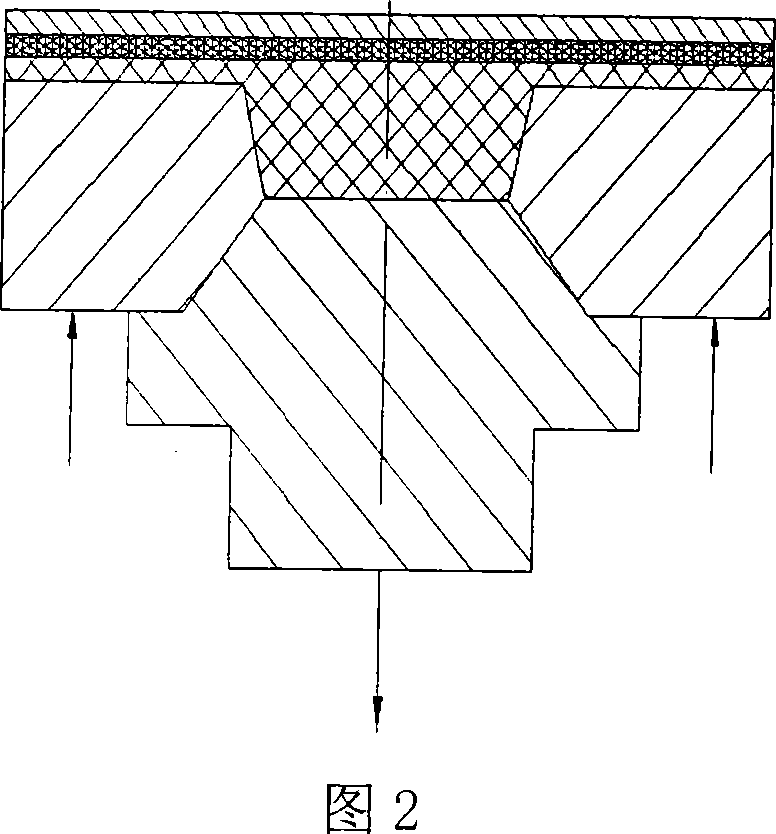

[0031] A method for testing the bond strength of a high-bond coating based on a pressure test device, which mainly consists of the following steps:

[0032] First take the same sample as the base material and process it into a sample blank consisting of a cone and a cylinder, wherein the cylinder is integrally connected with the small end of the cone, and the cone angle of the cone is between 2 times the base material Between the friction angle and 120 degrees;

[0033] Secondly, place the above-mentioned sample blank in a stepped support ring with a cone hole of the same cone angle, so that the cone part of the sample blank matches the taper hole. The diameter of the large step of the stepped support ring is The diameter of the small end of the taper hole is 2 to 4 times, the difference between the diameter of the small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com