Manufacture method of color filter, color filter and liquid crystal display device

A production method and color filter technology, which are applied in the fields of color filters, optics, instruments, etc., can solve the problems of weak bonding between substrates and color filters, complicated color filter manufacturing processes, and easy occurrence of defects. High rate, improved sensitivity, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] As described in the background technology, the material of the touch sensing electrode in the prior art usually selects ITO, but the impedance of ITO is relatively large, so the noise is relatively large, which affects the sensitivity of touch sensing; and the production process of the touch sensing electrode of the metal grid More complex, higher cost, lower yield.

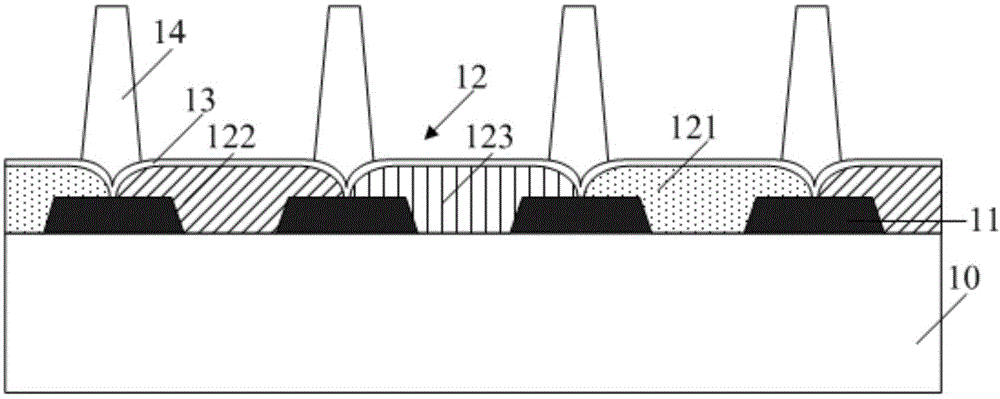

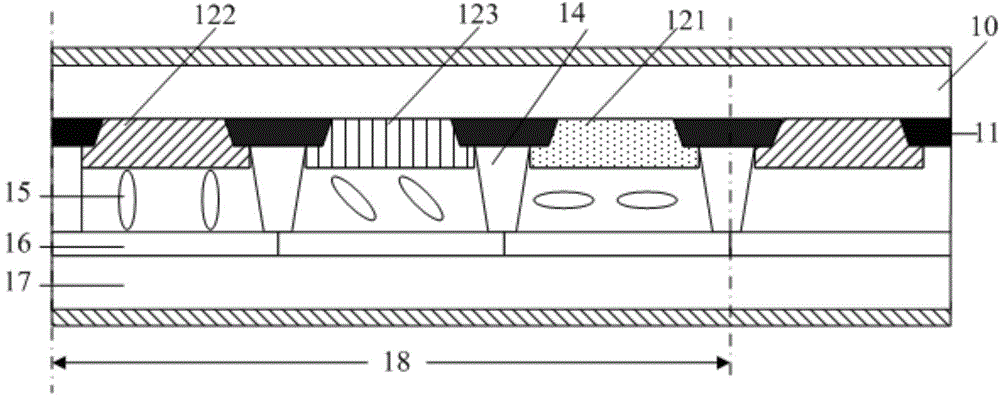

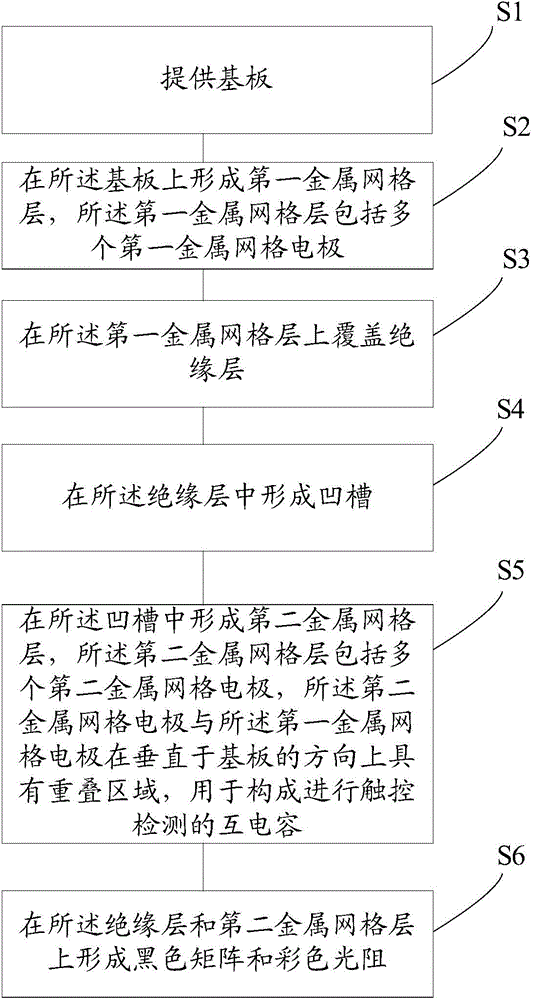

[0063] In order to solve the above-mentioned technical problems, the present invention provides a method for manufacturing a color filter, in which a plurality of first metal grid electrodes and second metal grid electrodes for mutual capacitance touch detection are directly formed on the substrate. A black matrix and a color photoresist for color filtering are formed above the first metal grid electrode and the second metal grid electrode. In the manufacturing method of the present invention, the electrodes used for touch detection are well compatible with the existing color filter manufacturing technolog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com