Thermoplastic resin composition, light reflector and method for producing molded article for light reflector

A kind of technology of light reflector and manufacturing method, applied in the field of thermoplastic resin composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

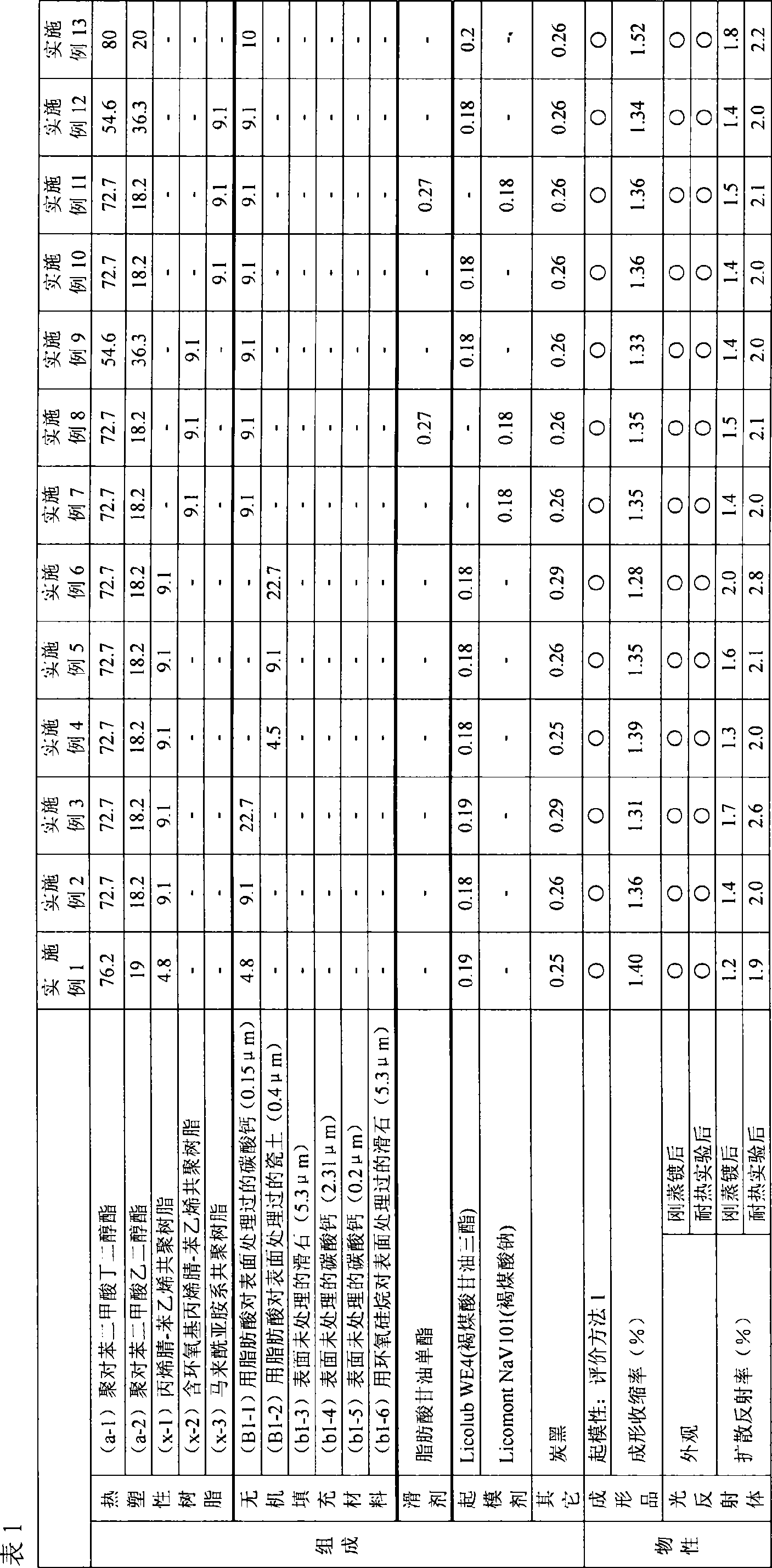

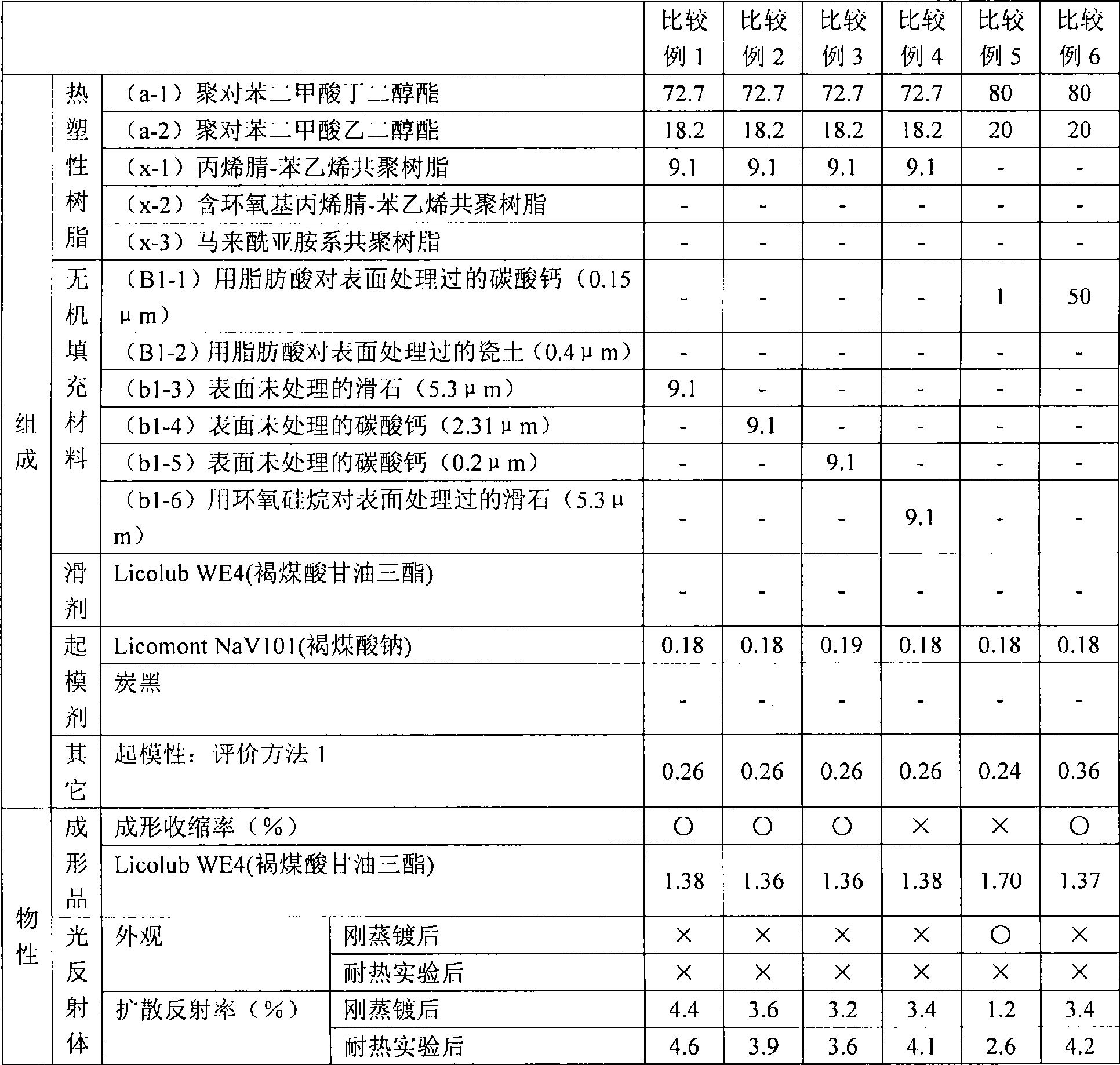

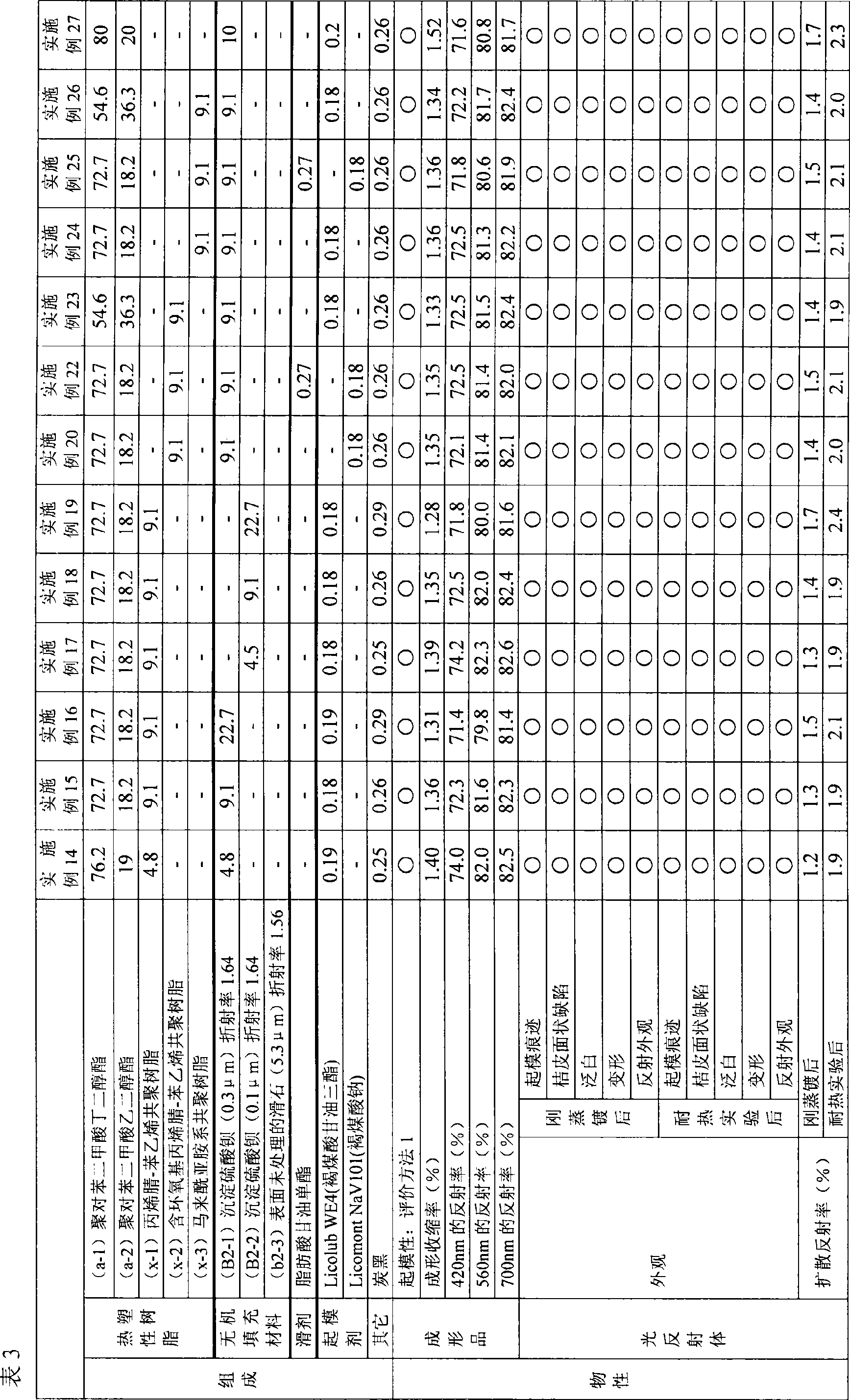

[0115] Hereinafter, the present invention will be described in more detail using examples and comparative examples, but the present invention is not limited thereto.

[0116] Evaluation method of surface roughness of metal mold

[0117] Using the non-contact three-dimensional measurement device NH-3 manufactured by Mitaka Koki, under the conditions of evaluation length 2mm, breaking value 0.8mm, and evaluation speed 0.3mm / sec, the surface of the metal mold was measured, and the arithmetic mean was obtained in accordance with JISB0601 standard Surface roughness Ra.

[0118] Evaluation method of resin

[0119] (1) Relative viscosity (ηsp / C)

[0120] Add 50ml of 1:1 (mass ratio) mixed solvent of phenol and tetrachloroethane (manufactured by Kanto Chemical Co., Ltd., trade name "PTM11") to 0.25g polybutylene terephthalate resin, Dissolve at 140°C for 10 to 30 minutes to obtain a solution. After adjusting its temperature in a constant temperature water tank at 25°C for 3 minute...

manufacture example 1

[0183] Production example 1 (acrylonitrile-styrene copolymer resin (x-1))

[0184] 115 parts by mass of distilled water, 1 part by mass of calcium (tri)phosphate, and 0.001 part by mass of Demol water-based dispersant P (manufactured by Kao Corporation) were put into a reaction tank and stirred. Then add 25 parts by mass of acrylonitrile, 75 parts by mass of styrene, 0.5 parts by mass of t-dodecyl mercaptan, 0.17 parts by mass of azobisisobutyronitrile, 0.003 parts by mass of ガフッツク GB-520 (Toho Kagaku Kogyo Co., Ltd.), after forming a suspension, the temperature was raised to 75° C., and kept for 240 minutes to complete the polymerization to obtain an acrylonitrile-styrene copolymer resin (x-1). The composition of the obtained (x-1) resin was acrylonitrile / styrene=34 / 66 (mass ratio).

manufacture example 2

[0185] Production example 2 (epoxy group-containing acrylonitrile-styrene copolymer resin (x-2))

[0186] 115 parts by mass of distilled water, 1 part by mass of calcium (tri)phosphate, and 0.001 part by mass of Demol water-based dispersant P (manufactured by Kao Corporation) were put into a reaction tank and stirred. Then add 23 parts by mass of acrylonitrile, 76.7 parts by mass of styrene, 0.3 parts by mass of glycidyl methacrylate, 0.5 parts by mass of t-dodecyl mercaptan, 0.17 parts by mass of azobisisobutyronitrile, 0.003 parts by mass of GAFAツクGB -520 (manufactured by Toho Chemical Industry Co., Ltd.), in the form of a suspension, the temperature was raised to 75° C., and kept for 240 minutes to complete polymerization to obtain epoxy group-containing acrylonitrile-styrene copolymer resin (x-2). The composition of the obtained (x-2) resin was acrylonitrile / styrene / glycidyl methacrylate=24.9 / 74.7 / 0.4 (mass ratio).

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com