Borehole wall stabilizing agent and preparation method thereof

A wellbore stabilizer and drilling fluid technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as adverse effects, large dosage, and single effect, and achieve excellent operability and increase bonding Abilities, effects of vulnerability to defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

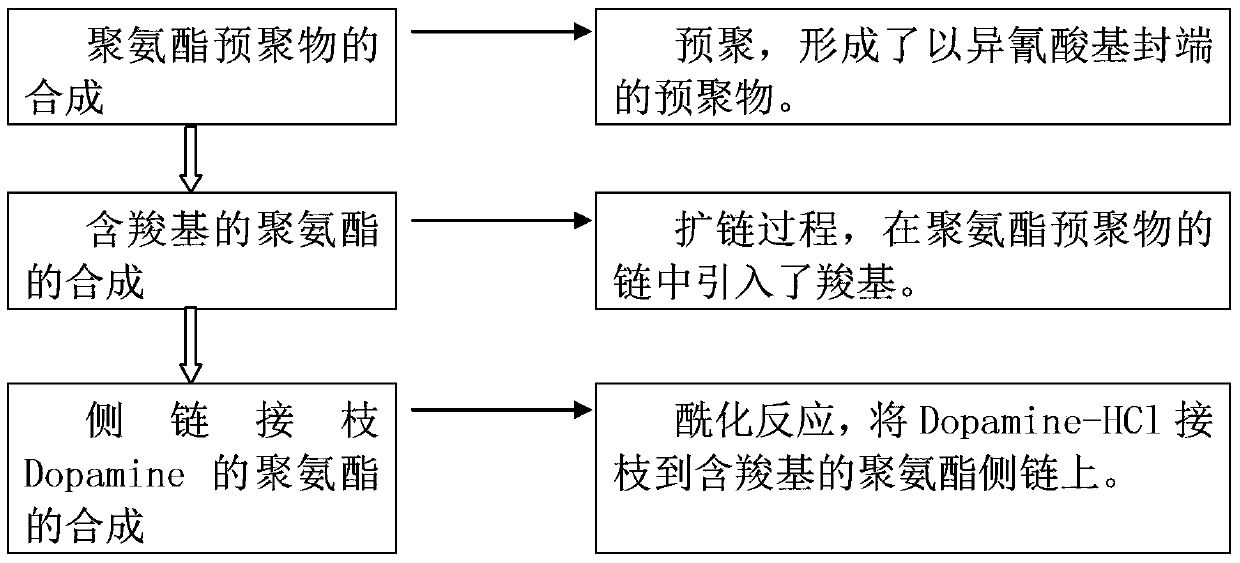

Method used

Image

Examples

Embodiment 1

[0046] The well wall stabilizer has the following components in weight percent: 21% isophorone diisocyanate; 48% polypropylene glycol; 13% dimethylol propionic acid; 18% dopamine hydrochloride.

[0047] The preparation method of above-mentioned well wall stabilizer is as follows:

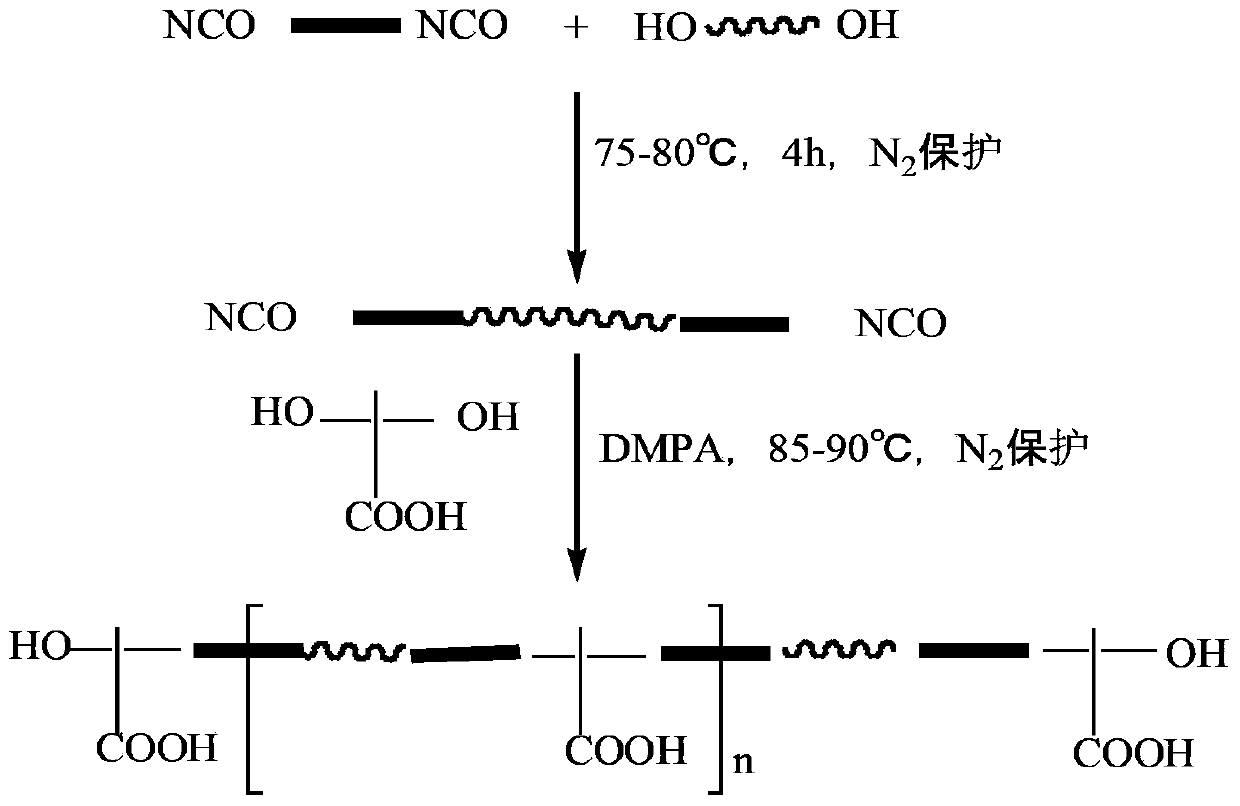

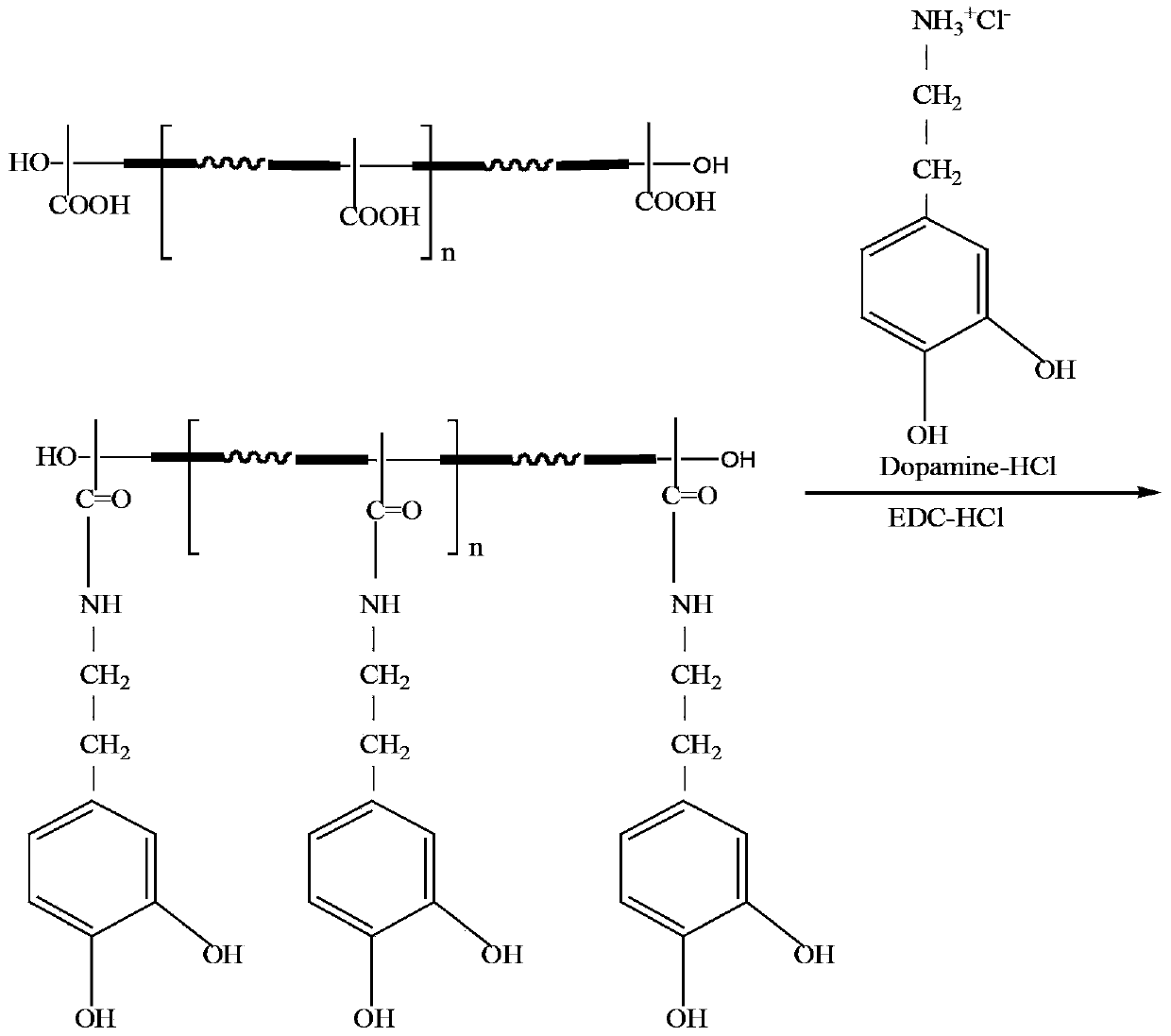

[0048]Select polypropylene glycol to accurately measure isophorone diisocyanate and polypropylene glycol according to the above weight percentage, place them in a reactor with N,N-dimethylformamide (DMF) as the solvent, and control the reaction temperature between 75-80°C , the reaction time is 4h, and N is passed through during the reaction 2 , the rotation speed of the synthesis process is maintained at 200 rpm. After the isocyanate-containing polyurethane is synthesized, the above weight percentage of dimethylol propionic acid (DMPA) is added for chain extension. The reaction temperature is 80-85 ° C, and the reaction time is For 5h, the reaction process passes through N 2 , stirring at a low s...

experiment example 2

[0054] Raw materials calculated by weight percentage: 18% isophorone diisocyanate; 60% polypropylene glycol; 8% dimethylol propionic acid; 14% dopamine hydrochloride.

[0055] Select polypropylene glycol, accurately measure isophorone diisocyanate and polypropylene glycol according to the above weight percentage, place them in a reactor with DMF as the solvent, control the reaction temperature between 75-80°C, and the reaction time is 4h. During the reaction Pass N 2 , the rotation speed of the synthesis process is maintained at 200 rpm. After the isocyanate-containing polyurethane is synthesized, the above weight percentage of dimethylol propionic acid (DMPA) is added for chain extension. The reaction temperature is 80-85 ° C, and the reaction time is For 5h, the reaction process passes through N 2 , stirring at a low speed of 250 rpm, the prepared solution is colorless transparent viscous liquid, the obtained solution is precipitated with deionized water for 3 times, washed...

Embodiment 3

[0061] Raw materials calculated by weight percentage: 25% isophorone diisocyanate; 38% polypropylene glycol; 15% dimethylol propionic acid; 22% dopamine hydrochloride.

[0062] Select polypropylene glycol, accurately measure isophorone diisocyanate and polypropylene glycol according to the above weight percentage, place them in a reactor with DMF as the solvent, control the reaction temperature between 75-80°C, and the reaction time is 4h. During the reaction Pass N 2 , the rotation speed of the synthesis process is maintained at 200 rpm. After the isocyanate-containing polyurethane is synthesized, the above weight percentage of dimethylol propionic acid (DMPA) is added for chain extension. The reaction temperature is 80-85 ° C, and the reaction time is For 5h, the reaction process passes through N 2 , stirring at a low speed of 250 rpm, the prepared solution is colorless transparent viscous liquid, the obtained solution is precipitated with deionized water for 3 times, washe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com