Active oil-washing sand consolidating agent and preparation method and application thereof

A sand-fixing agent and oil-washing technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as residues in the well, high workover costs, and influence on later operations, so as to achieve excellent operability and not easy Defects, the effect of guaranteed strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

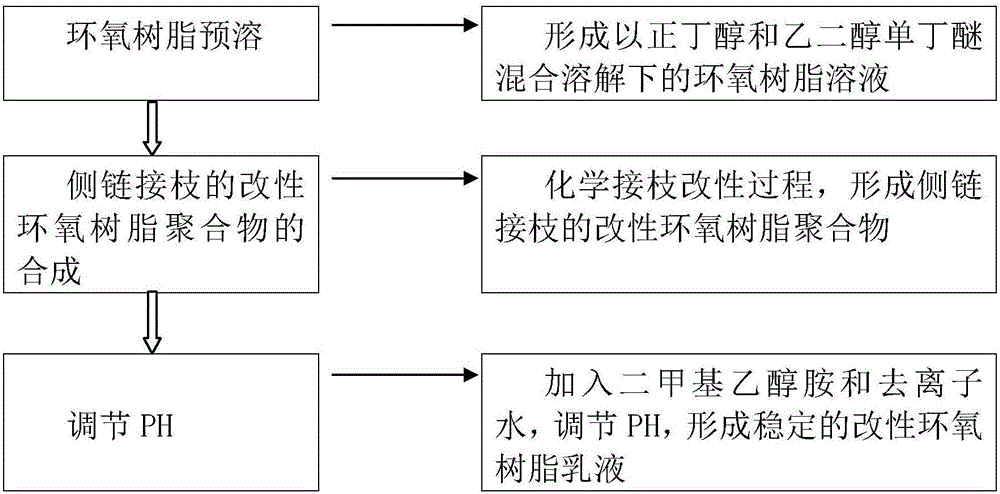

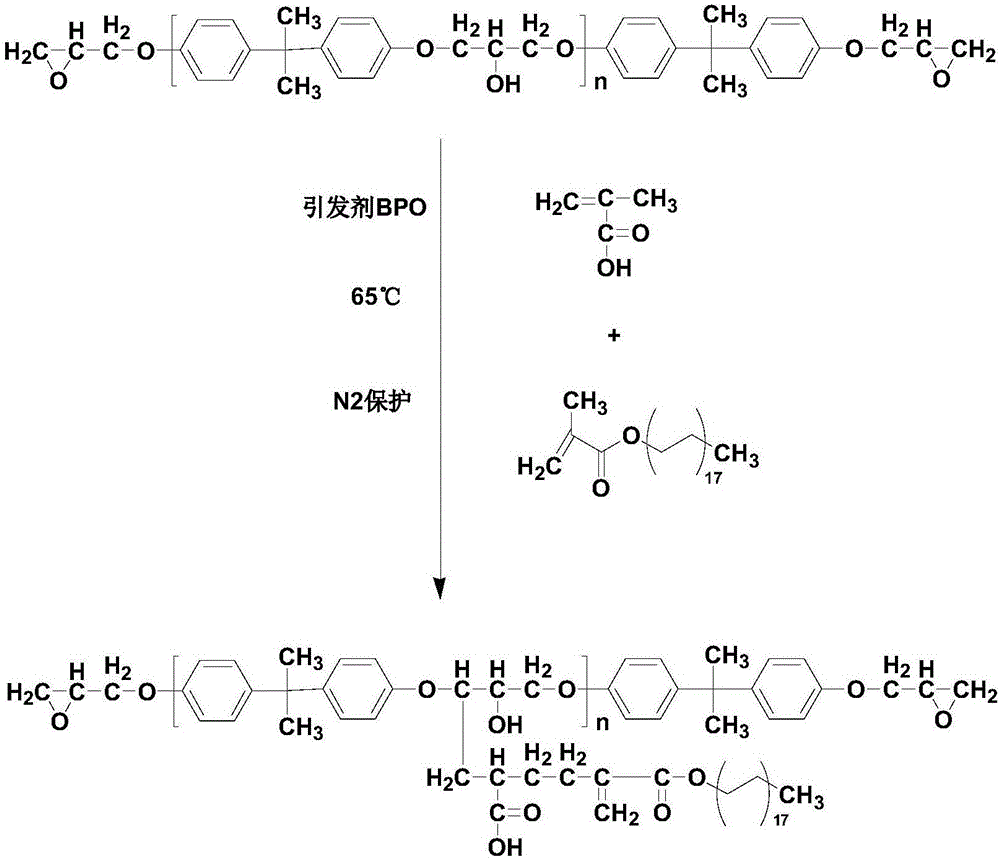

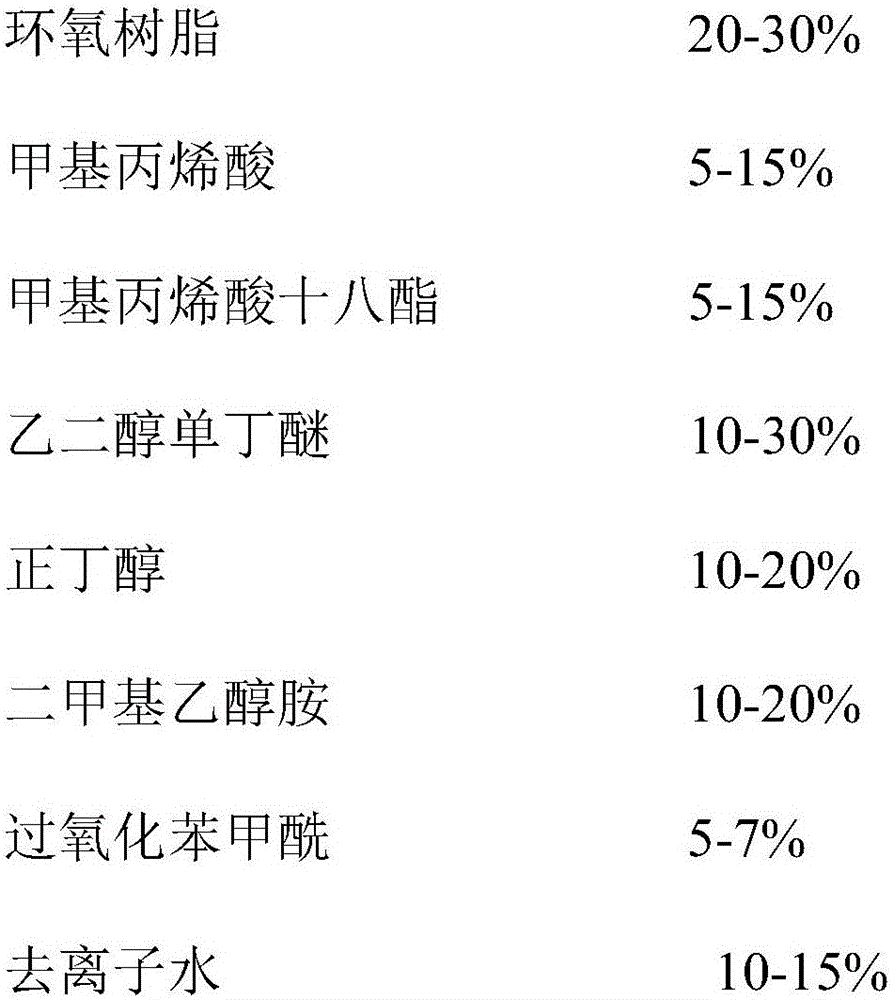

Method used

Image

Examples

Embodiment 1

[0035] According to m (oil): m (sand) = 1: 4, accurately weigh the clean sand (m sand) and crude oil (m oil) in the oil field, mix them thoroughly, put them in an oven, and age them at the reservoir temperature for 4 days, stirring frequently in the middle Ensure that the oil content is uniform throughout the oil sands. The oil content of the oil sand is m oil / (m sand+m oil).

[0036] Take a certain amount of modified epoxy resin emulsion, curing agent and silane coupling agent KH550 or KH570 and stir evenly, then add an appropriate amount of oil-containing quartz sand (particle size 0.4-0.8mm), stir well, put it into one end and plug it tightly with a rubber stopper Shake well and compact, then moisten with water or emulsion, soak in a constant temperature water bath at 60°C-70°C for 72h-96h, break the glass tube, take out the consolidated body, and use a core cutter Cut the consolidated body into 2.5cm long cores for testing the compressive strength.

[0037] The consolida...

experiment example 2

[0039] The viscosity of the crude oil in the heavy oil block of the No. 1 Oil Production Plant of an oilfield is 25-90pa.s (30℃), and it contains 15% asphaltenes. The oil layer has high sand content and severe sand production. At present, the average daily production of oil well sand is more than 100 square meters, and the average oil content is 20% to 30%. The production time of steam huff and puff is longer, and the effect of steam injection and oil production decrease obviously. The study of the oil washing and sand fixing system in the field shows that the system can effectively stabilize the formation, and have a higher permeability, remove the clogging of the oil layer, and increase the productivity of the oil well. The oil washing and sand-fixing agent sand-fixing operation of 19 wells within the oil production cycle can extend the oil production cycle by 283 days, increase the cumulative production by 573 tons, greatly reduce the sand production, and have a long effec...

Embodiment 3

[0041] A certain oilfield was put into development in 1995. It is a complex fault-block reservoir of unconsolidated sandstone. Due to the shallow burial of oil layers, loose intertwining and serious sand production. Sand production and clogging are the main problems encountered in the development of this oilfield. Of the 18 wells put into production in a certain block of the oilfield at the initial stage, 10 wells failed to produce normally due to sand production and clogging. The results of the implementation of the sand-fixing system show that: 8 well-times were applied to the measure wells, 6 well-times were successful, the success rate was 75%, and the effective period of sand control reached more than 500 days. The average single well daily fluid of sand-controlling oil wells is 8.4, daily oil is 1.4, and water cut is 70%. Among them, Well Qu 104 Xie Geng 2 had a daily fluid flow of 20 cubic meters, a daily oil production of 10 tons, and a cumulative production increase o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com