Binding agent for powder injection moulding, preparation method and application method of binding agent

The technology of a binder and a copolymer is applied in the field of powder injection molding to achieve the effect of simple and fast preparation method and improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

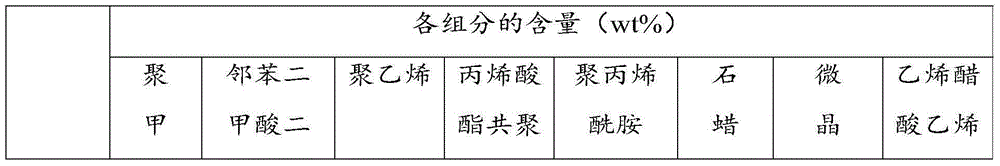

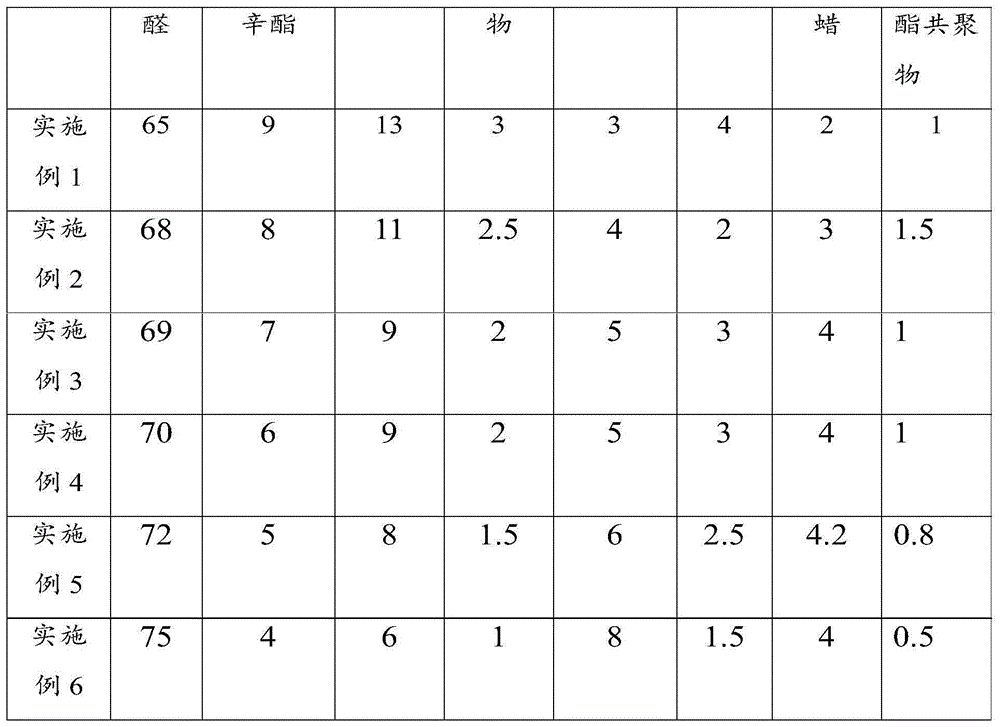

[0033] According to the proportioning (as shown in Table 1), polyoxymethylene, dioctyl phthalate, and polyethylene are used as the main body, and acrylate copolymer, polyacrylamide, paraffin, microcrystalline wax, and ethylene vinyl acetate copolymer are added in Mix in a kneader to obtain the binder for powder injection molding prepared in this example.

Embodiment 2

[0035] According to the proportion (as shown in Table 1), polyoxymethylene, dioctyl phthalate, polyethylene, acrylate copolymer, polyacrylamide, paraffin wax, microcrystalline wax, and ethylene vinyl acetate copolymer were placed in the mixer , according to the mixing rate of 40 rpm, mixing at a mixing temperature of 40 ° C for 3 hours, to obtain the binder for powder injection molding prepared in this example.

Embodiment 3

[0037] According to the proportion (as shown in Table 1), polyoxymethylene, dioctyl phthalate, polyethylene, acrylate copolymer, polyacrylamide, paraffin wax, microcrystalline wax, and ethylene vinyl acetate copolymer were placed in the mixer According to the mixing rate of 40 rpm, mixing at a mixing temperature of 130° C. for 0.5 hours, the binder for powder injection molding prepared in this example was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com