Copper plating tank

A technology of copper plating and plating solution, applied in circuits, semiconductor devices, etc., can solve the problems of uneven thickness of circuit board plating, aggravate workpiece edge effects, etc., and achieve the effect of improving electroplating efficiency and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

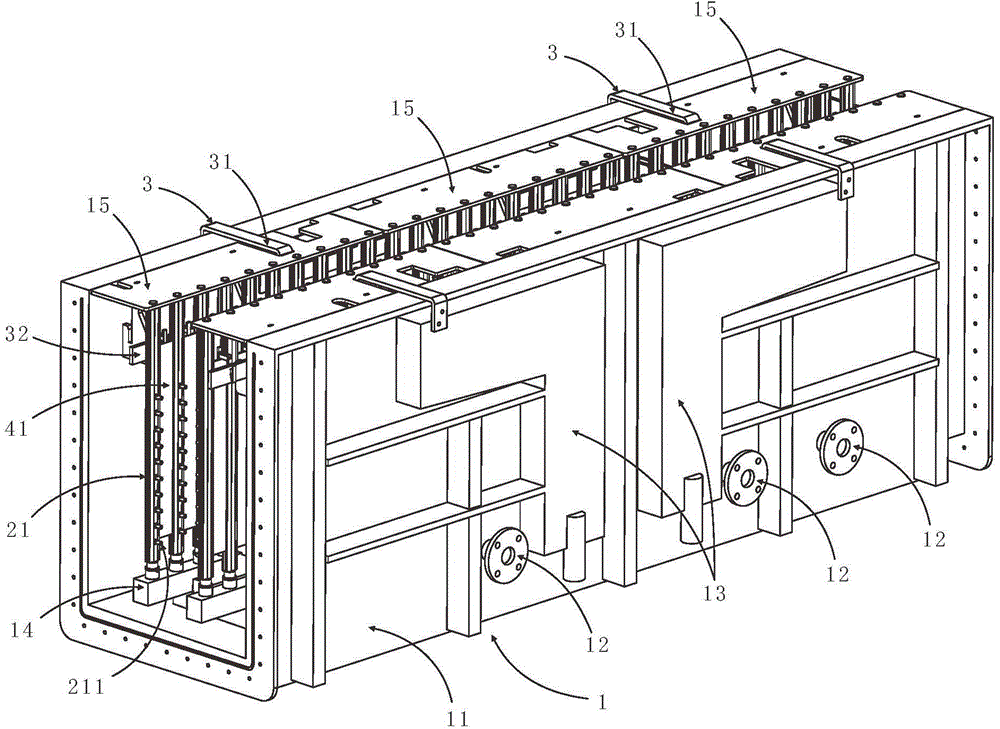

[0040] Such as figure 1 As shown, the copper plating tank of the present invention includes a tank body 1, a nozzle array located in the tank body 1, an anode hanger 3, and an anode array, wherein:

[0041] The tank 1 is used to accommodate the electroplating solution, and is composed of a U-shaped tank unit 11; the side wall of the U-shaped tank unit 11 has at least one plating solution inlet pipe 12, and at least one plating solution overflow recovery device 13; The plating solution inlet pipe 12, the plating solution overflow recovery device 13 are in communication with the plating solution circulation system (not shown) outside the tank body 1; According to the needs, a plurality of U-shaped tank units 11 can also be sequentially connected to form a longer tank;

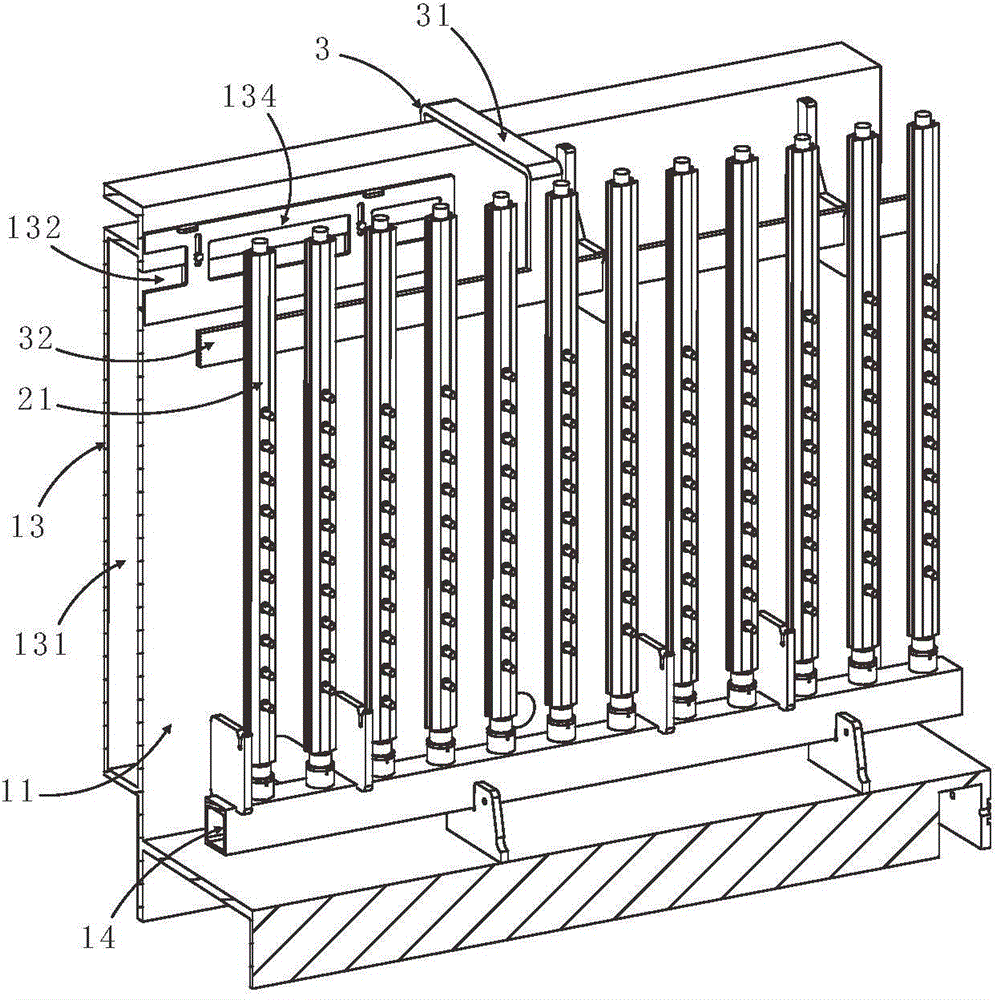

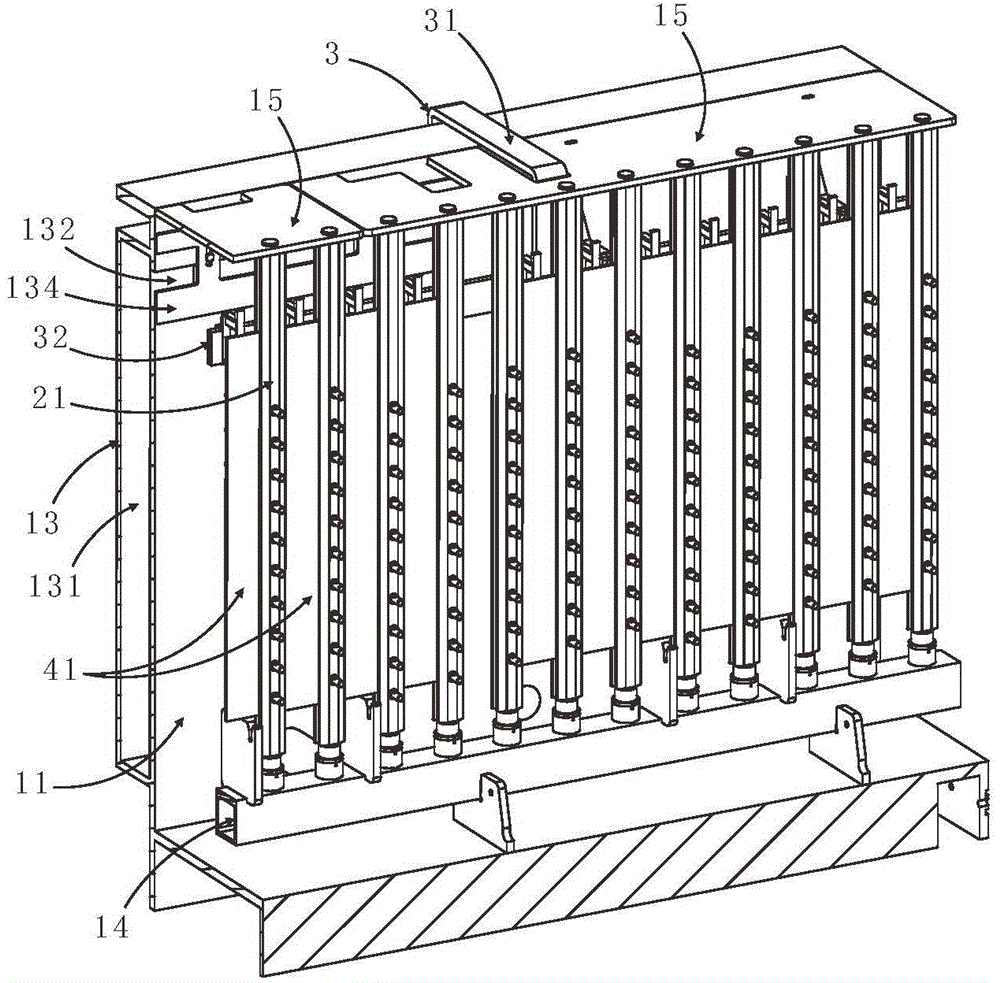

[0042] Nozzle arrays, such as figure 2 As shown, there are a plurality of nozzles 21 side by side, the top of the nozzles 21 is sealed, the bottom of the nozzles 21 communicates with the plating solution inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com