Electroplating device for printed circuit board

A technology for printed circuit boards and electroplating devices, which is applied to circuits, electrodes, electrolytic components, etc., can solve the problems of inability to reduce energy consumption, difficult to reduce, and difficult to improve electroplating efficiency, so as to improve electroplating efficiency, reduce output power, and improve The effect of thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

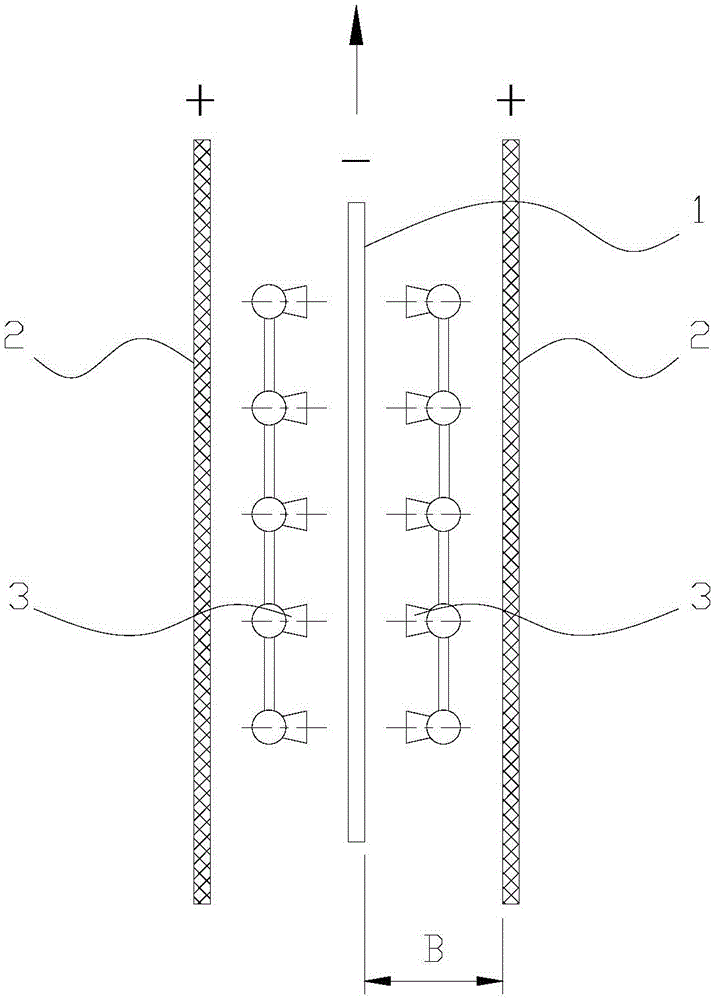

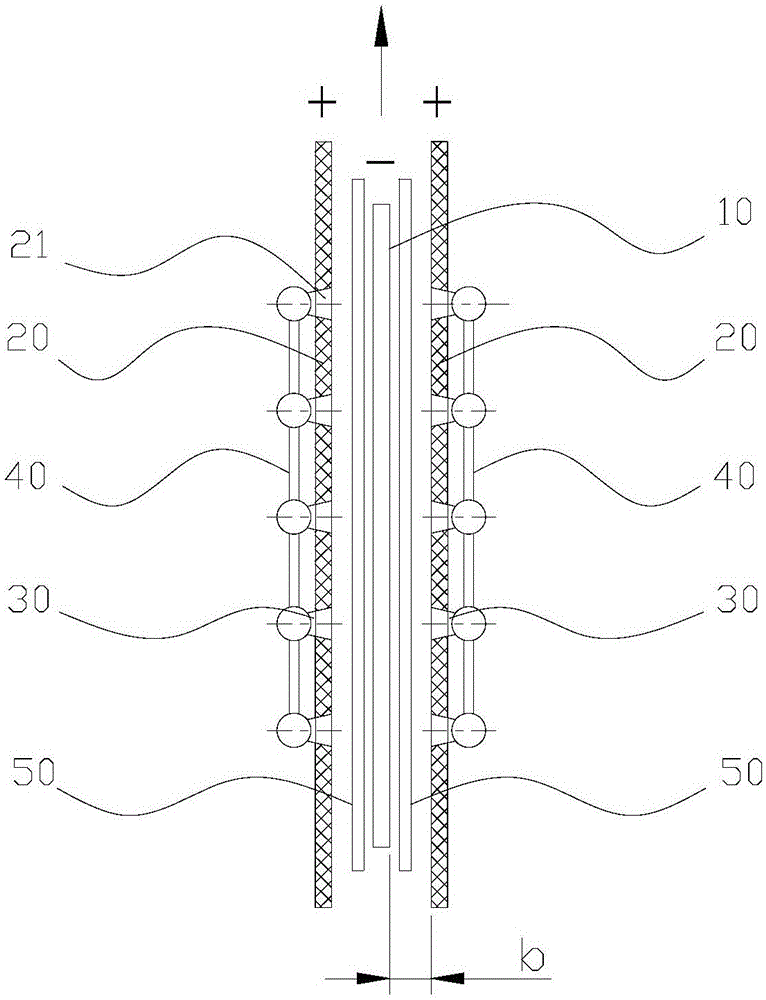

[0025] see figure 2 and 3 , an electroplating device for a printed circuit board, comprising: an electroplating tank for the passage of a printed circuit board 10 in the middle, anode plates 20 arranged on both sides of the printed circuit board 10, arranged in the electroplating tank with the opening facing the printed circuit A plurality of nozzles 30 of the board 10 , nozzles 40 communicating with the plurality of nozzles 30 , insulating baffles 50 arranged on both sides of the printed circuit board 10 , and a vertical lifting device for driving the insulating baffles 50 to reciprocate up and down. When only one side of the printed circuit board 10 is electroplated, an anode plate 20 can be provided only on the outside of the side to be electroplated.

[0026] The anode plate 20 is provided with a through hole 21 penetrating along its thickness direction, the nozzle 30 is fixedly arranged on the anode plate 20 and the opening of the nozzle 30 matches the through hole 21 ....

Embodiment 2

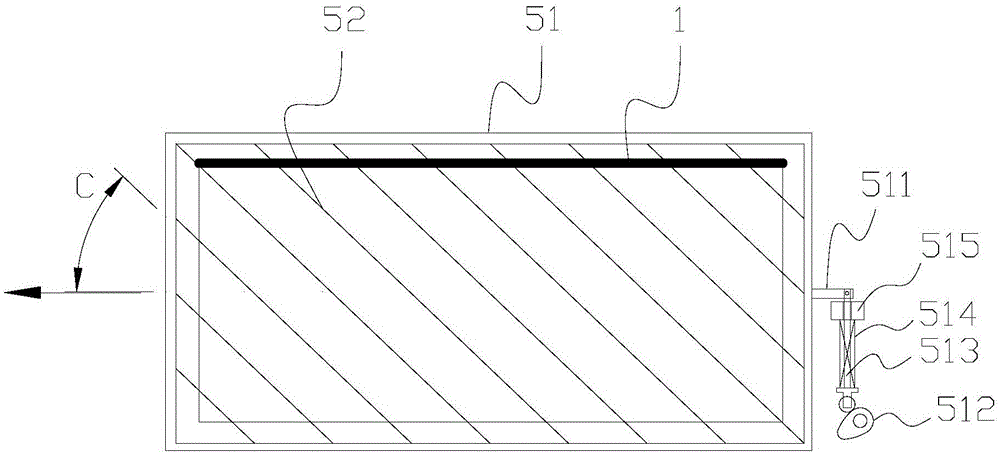

[0033] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that in the insulating baffle, the plurality of insulated wires are included along the moving direction of the printed circuit board 10 through the electroplating bath (such as Figure 4 The direction indicated by the arrow) the first group of insulated wires 52 arranged in parallel at a first inclination angle, the second group of insulated wires 53 arranged in parallel at a second inclination angle with the moving direction of the printed circuit board 10 passing through the electroplating tank, the second group of insulated wires 53 One group of insulated wires 52 and the second group of insulated wires 53 are arranged to cross each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com