Photovoltaic cell horizontal electroplating equipment and method

A photovoltaic cell and electroplating equipment technology, applied in plating tanks, electrolytic components, electrolytic processes, etc., can solve problems such as long product size and poor quality of photovoltaic cell coating, to increase uniformity, improve electroplating efficiency, and avoid rough edges problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

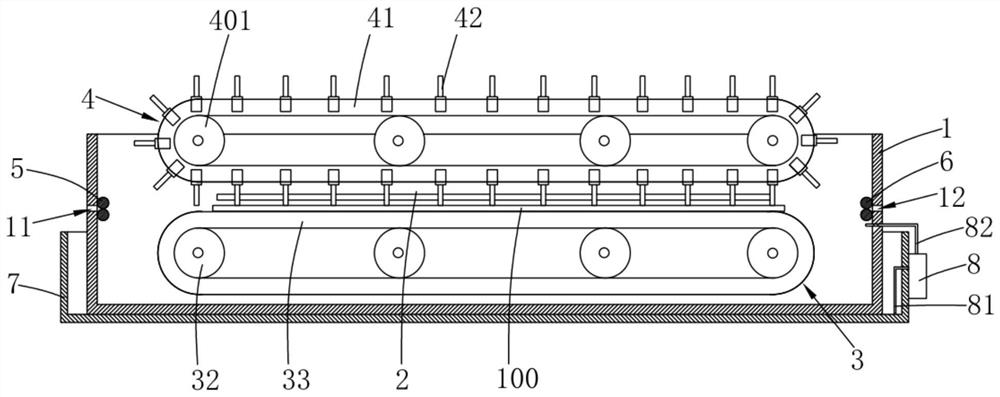

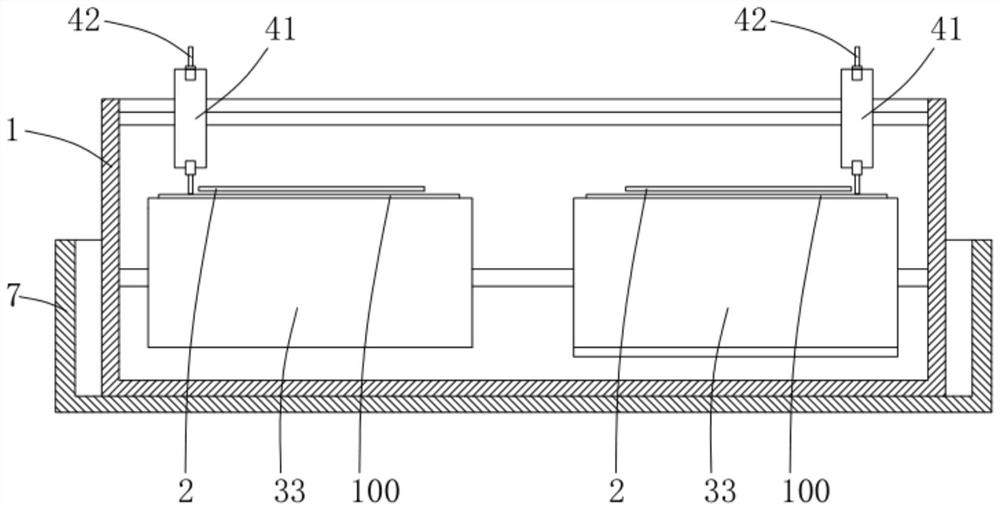

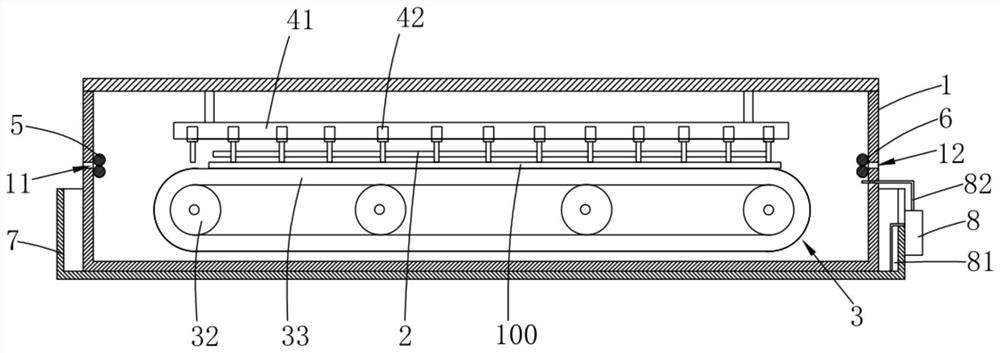

[0035] Please refer to Figure 1-Figure 2 , an embodiment of the present invention provides a horizontal electroplating equipment for photovoltaic cells, including:

[0036] An electroplating tank 1, the electroplating tank 1 is equipped with an electroplating solution, one end of the electroplating tank 1 is provided with an inlet 11, and the other end of the electroplating tank 1 is provided with an outlet 12 opposite to the inlet 11;

[0037] An anode part 2 arranged in the electroplating tank 1 and located below the liquid level of the electroplating solution;

[0038] The cell moving mechanism 3 provided in the electroplating tank 1 is used to drive the cell 100 to move from the entrance 11 to the exit 12, so that the cell 100 moves relative to the anode part 2 in the electroplating solution to realize electroplating;

[0039] The cathode conductive assembly 4 arranged in the electroplating tank 1 includes a rotary motion part 41 driven by a driving device, and a plurali...

Embodiment 2

[0081] The embodiment of the present invention also provides a method for electroplating photovoltaic cells using the photovoltaic cell horizontal electroplating equipment of the first embodiment, the method includes the following steps:

[0082] a. The cell moving mechanism 3 drives the cell 100 to move from the inlet 11 to the outlet 12, so that the cell 100 enters the electroplating tank 1 and moves relative to the anode 2 in the electroplating solution;

[0083] In this step, the battery piece moving mechanism 3 drives the battery piece 100 of the battery piece 100 to enter the electroplating tank 1 from the inlet 11, and the battery piece moving mechanism 3 continues to drive the battery piece 100 to move the battery from the inlet 11 to the outlet 12. piece 100, so that the battery piece 100 moves relative to the anode part 2 in the electroplating solution, and at the same time cooperates with the rotating movement part 41 to drive a plurality of cathode conductive probes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com