Plating limit device, plating equipment using same and plating method using same

A technology of limiting device and electroplating equipment, which is applied in the direction of application, sliding fastener components, fasteners, etc., can solve the problems of no arbitrary bending, limit the coating speed on the zipper strip, and produce spots on the electroplating layer, so as to achieve high electroplating efficiency , Improve the appearance quality, the effect of high appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

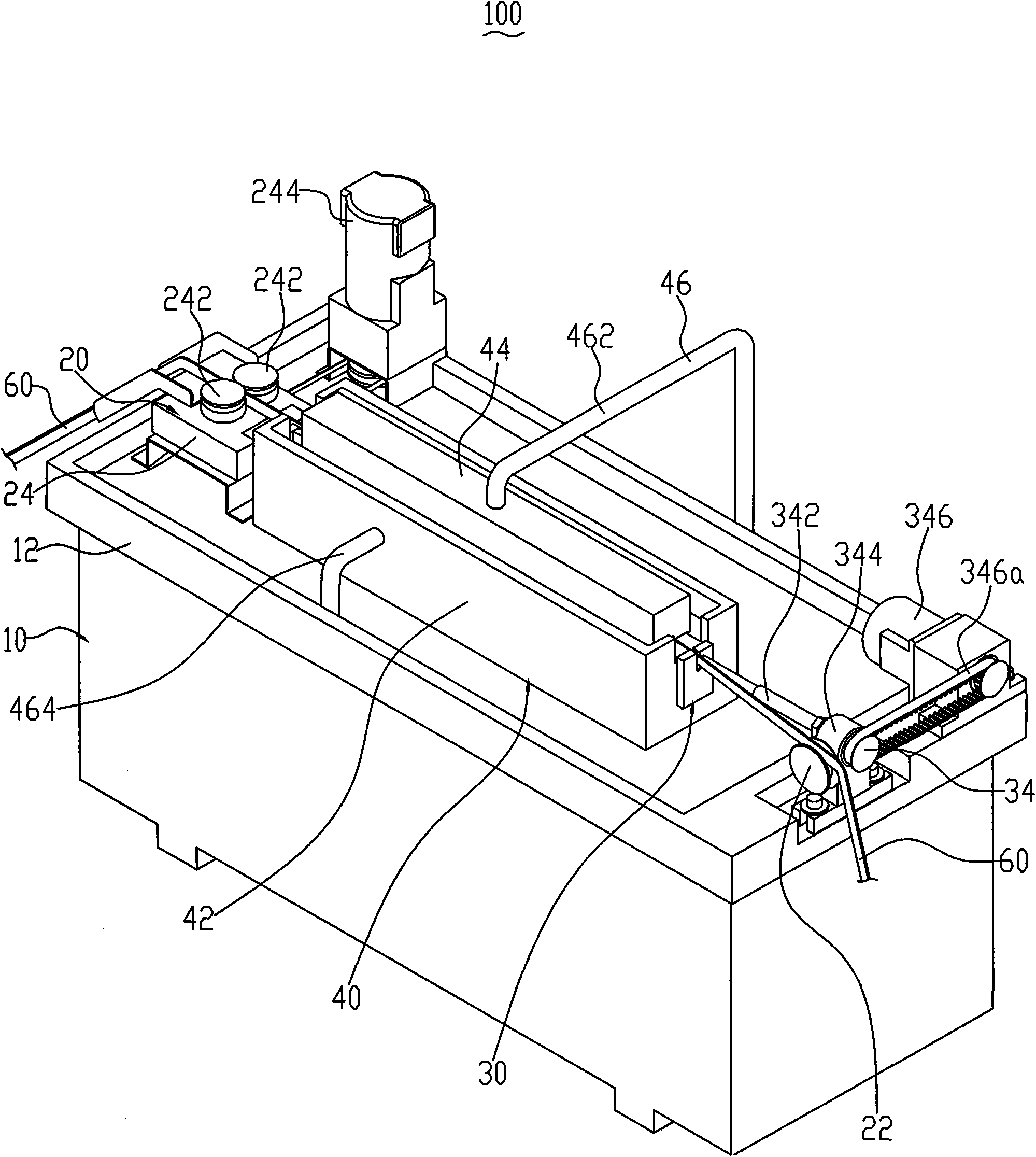

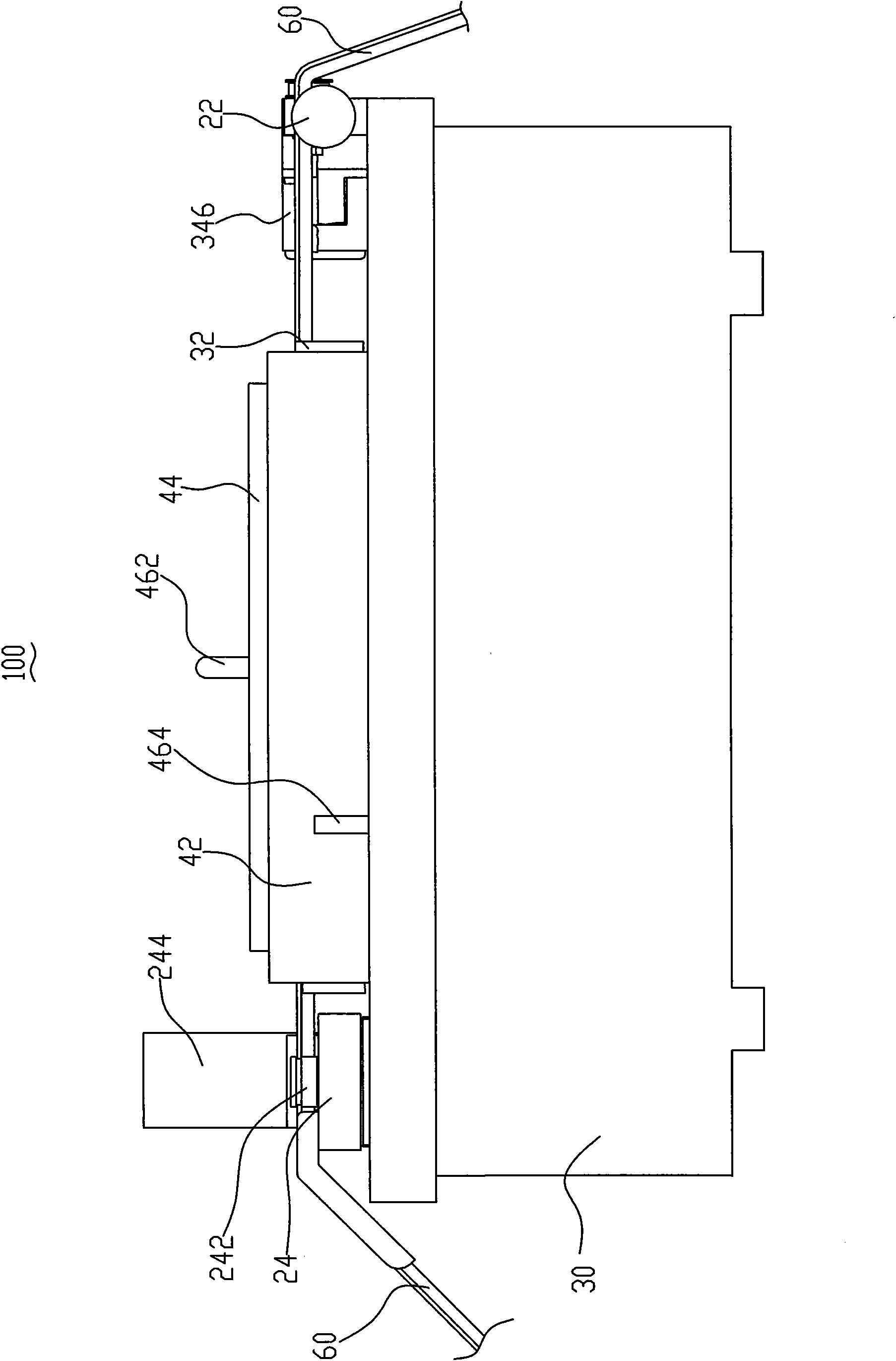

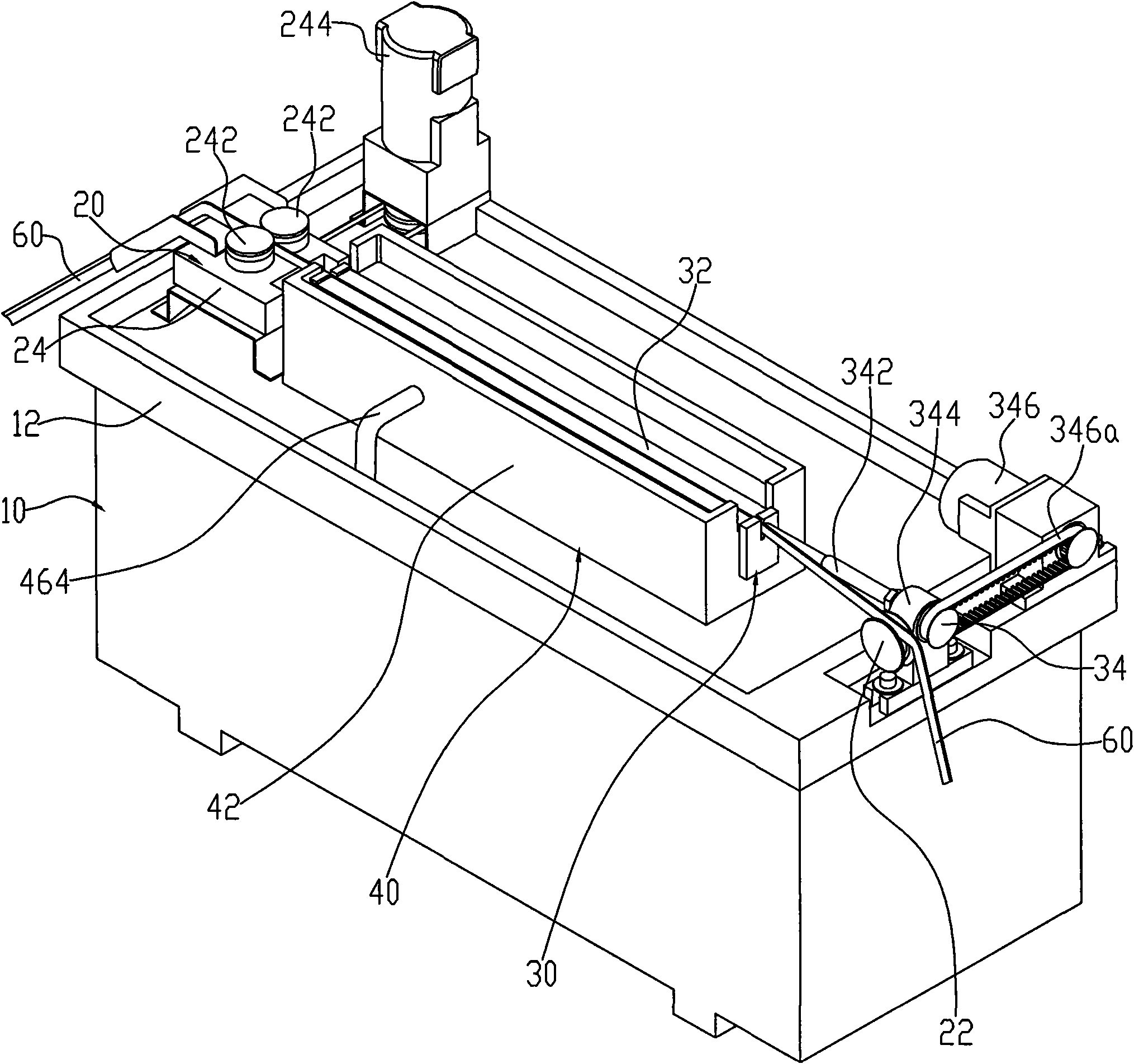

[0035] The chain teeth 64 of the single chain 60 are made of brass. The electroplating equipment 100 is used to electroplate the chain teeth 64 of the single chain 60. The electroplating steps are as follows:

[0036] Preparation before plating includes carrying out surface mechanical treatment to the chain teeth 64 of the single chain 60, such as polishing the chain teeth 64, deburring edges, etc.; degreasing, cleaning, and removing stains on the surface of the chain teeth 64; electroplating, using the The electroplating equipment 100 electroplates the single chain 60 to form an electroplating layer on the surface of the chain elements 64 of the single chain 60 ; after plating, the electroplated single chain 60 is cleaned, dried, and coated with brightener.

[0037] In the above electroplating step, the composition of the electroplating solution is: nickel sulfate 120 g / L, nickel chloride 30 g / L, boric acid 40 g / L, temperature 45°C-55°C, pH value 3.8-4.5. The electroplating c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com