Method for painting fluoro resin inside slender metal tube

A metal tube and fluororesin technology, which is applied in the directions of cleaning methods using liquids, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of unsatisfactory anti-corrosion performance of anti-corrosion coatings, poor coating construction technology, and weak metal bonding. and other problems, to achieve the effect of automatic production, high utilization rate of paint, and improvement of working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

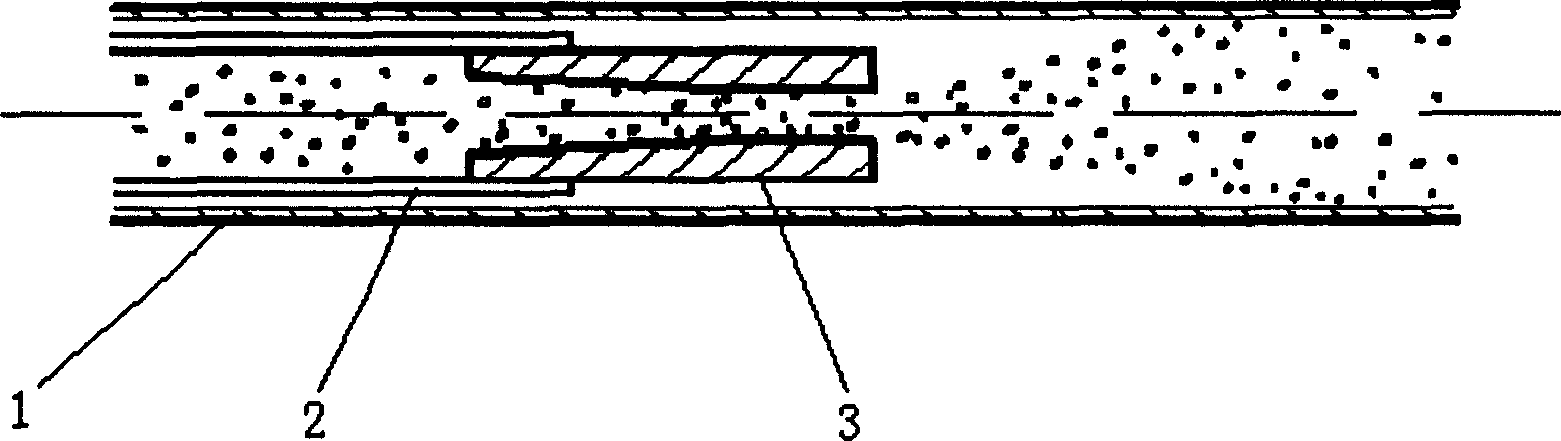

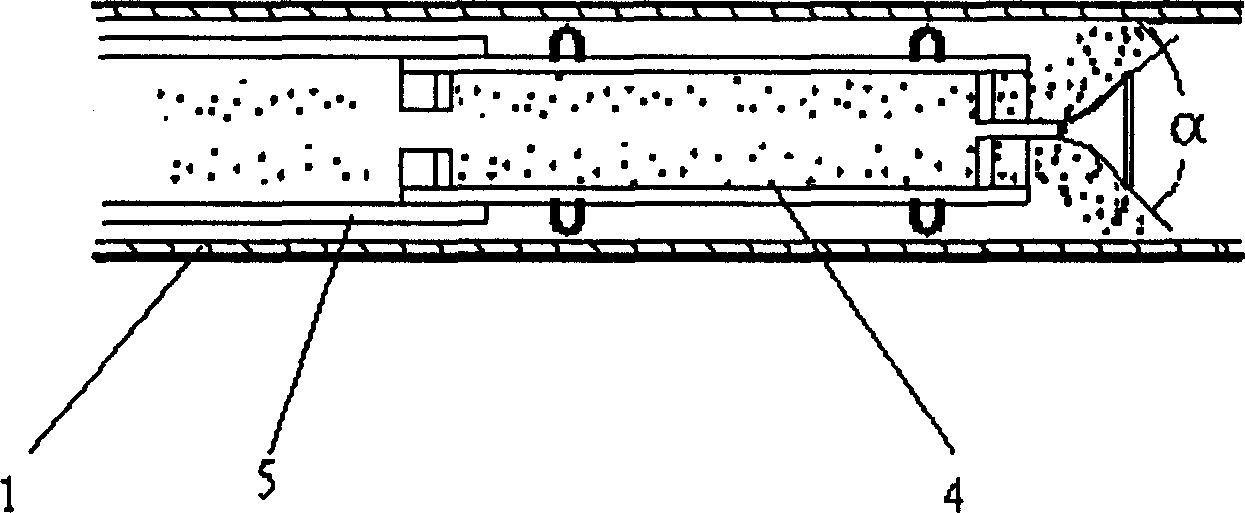

[0035] (1) Cleaning in the slender metal tube; cleaning devices such as figure 1 .

[0036]Put the slender metal tube 1 into a high-temperature furnace at a temperature of 300°C for 2 hours, then send the sandblasting and carrier gas to the spray nozzle of the sandblasting gun 3 through the sand delivery pipe 2 extending into the slender metal tube 1 , the wind pressure of the carrier gas is 0.25MPa, the particle size of the sandblasting is 0.3-1.0mm, the linear velocity of the carrier gas ejected from the nozzle is 300 m / s, and the content of the sandblasting in the carrier gas is 200-500 kg / m 3. Starting from the top of the elongated metal pipe 1, the sandblasting gun 3 moves in the opposite direction at a speed of 0.01-0.03 m / s. After sandblasting and cleaning, the inner surface of the elongated metal pipe has a roughness of 10 μm; the depth of the anchor pattern reaches 100μm;

[0037] Said elongated metal pipe 1 is selected from seamless carbon steel pipes, the outer di...

Embodiment 2

[0047] Cleaning and spraying equipment are as embodiment 1.

[0048] (1) Cleaning inside the slender metal tube;

[0049] Put the slender metal tube 1 into a high-temperature furnace at a temperature of 300°C for 2 hours to burn off the oil, and then send the sandblasting and carrier gas to the sandblasting gun through the sand delivery tube 2 extending into the slender metal tube 1 3 sprayed from the nozzle, the wind pressure of the carrier gas is 0.4MPa, the particle size of the sandblasting is 0.3 ~ 1.0mm, the linear velocity of the carrier gas ejected from the nozzle is 350 m / s, and the content of the sandblasting in the carrier gas is 300 kg / m3, from the top of the slender metal pipe 1, the sandblasting gun 3 moves in the opposite direction at a speed of 0.03 m / s. After sandblasting, the inner surface of the slender metal pipe has a roughness of 10 μm and anchor lines The depth reaches 60μm;

[0050] Said elongated metal pipe 1 is selected from seamless carbon steel pip...

Embodiment 3

[0059] Cleaning in the elongated metal tube is the same as in Example 1.

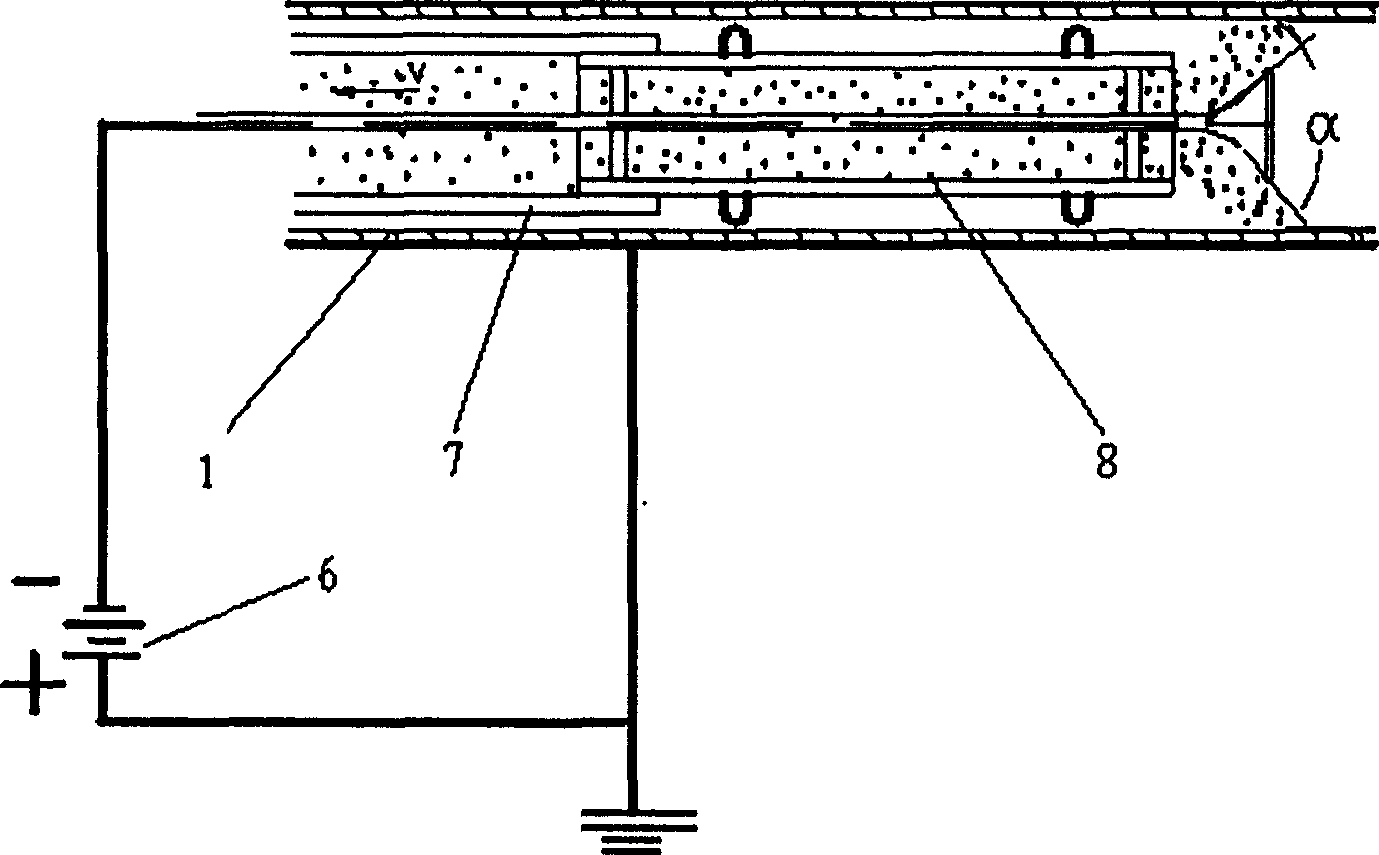

[0060] use as image 3 Electrostatic spraying device for spraying:

[0061] The air with a pressure of 0.2MPa will send the EK1959DGN fluorine paint to the muzzle of the electrostatic spray gun 8 with a diversion cup through the powder delivery pipe 7 extending into the slender metal pipe 1, and the angle α of the nozzle outlet is 45°; the electrostatic spray gun 8 is connected to the negative pole of the DC power supply 9, and the slender metal tube 1 is connected to the positive pole of the DC power supply 6, and the EK1959DGN fluorine paint sprayed from the muzzle of the electrostatic spray gun 8 is adsorbed on the inner wall of the slender metal tube, The voltage of the DC power supply 6 is 80KV, and the content of the solvent having the primer resin dissolved in the gas ejected from the muzzle is 2 kg / m 3 carrier gas, and the linear velocity of the gas ejected from the muzzle of the electrostatic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com