Impact leakage preventing device of suspending downspout column plate

A downcomer and anti-shock technology, applied in the direction of distillation separation, chemical instruments and methods, separation methods, etc., can solve problems such as unstable operation, and achieve the effects of avoiding vicious short circuits, low cost, and improved mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

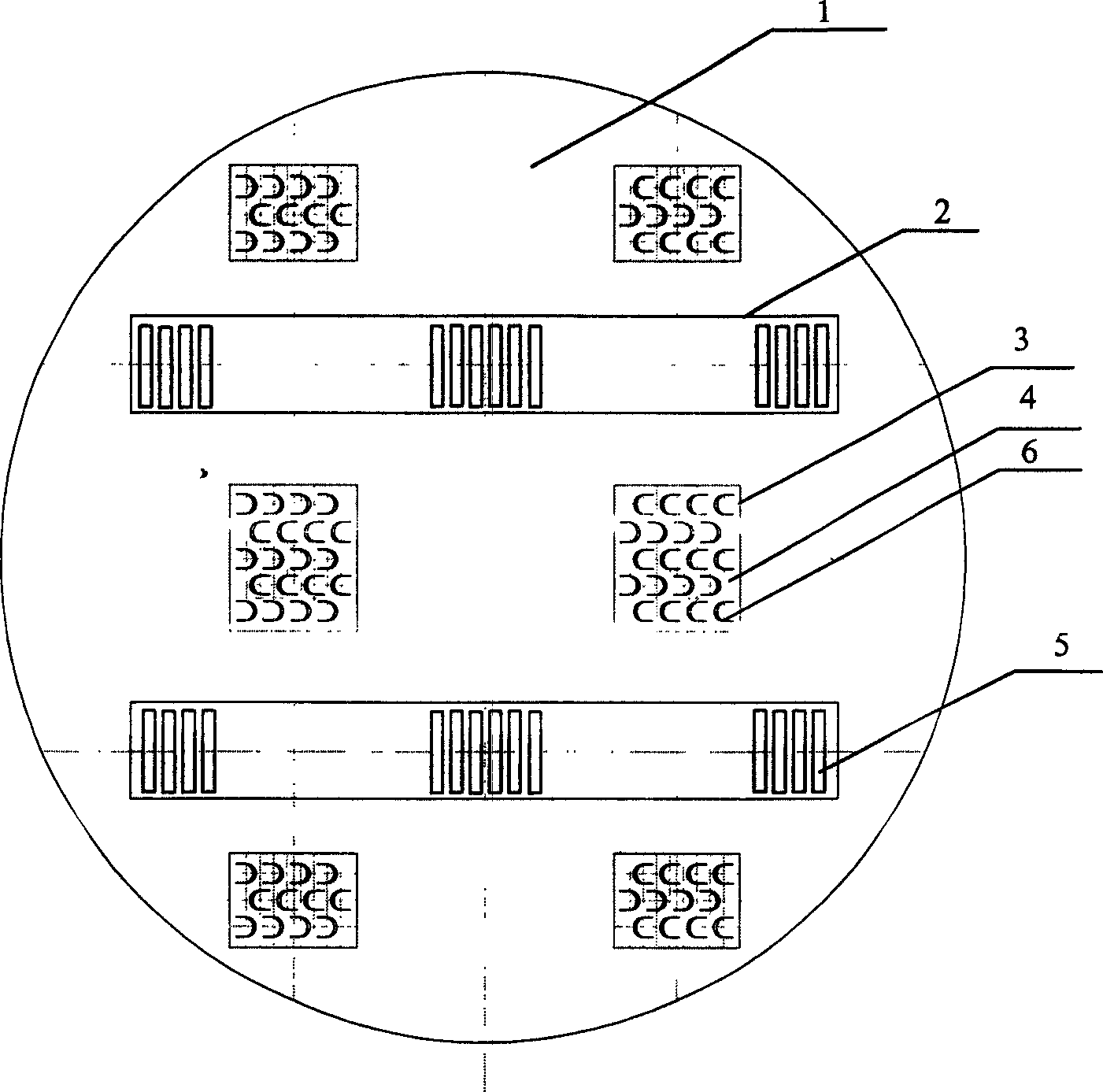

[0019] Embodiment: Below in conjunction with accompanying drawing, the present invention will be further described.

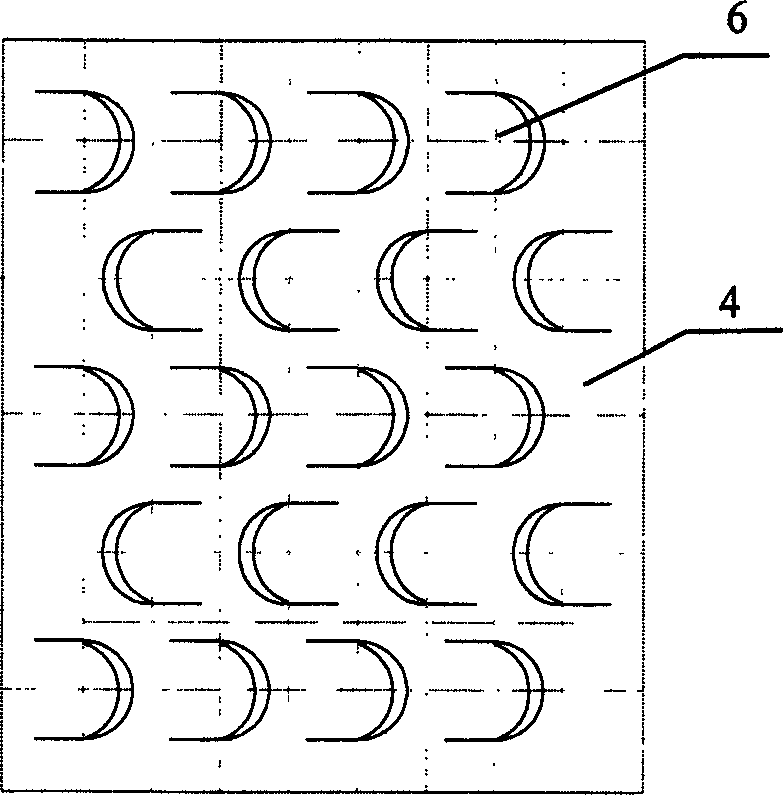

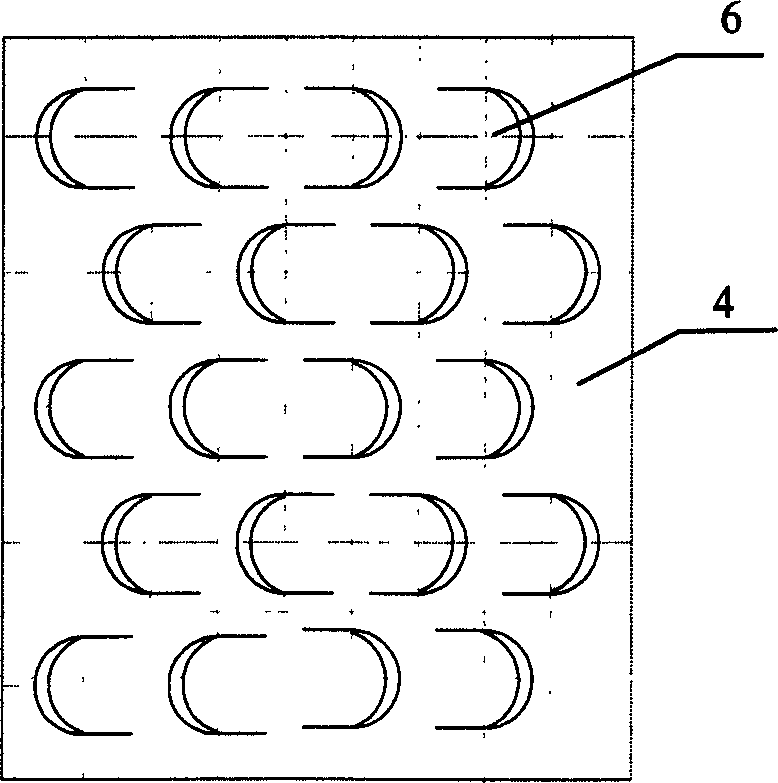

[0020] The anti-impact leakage device 4 of the suspended downcomer tray is characterized in that the anti-impact leakage device 4 of the suspended downcomer tray consists of multiple rows of oblique holes punched on the liquid-receiving bubbling area 3 of the tray 1 The multi-row oblique holes can be composed of two parts of oblique holes 6 with opposite inclination directions and the same number (as shown in Figure 2(a)), or two adjacent rows of oblique holes with opposite inclination directions and two adjacent rows The same number of inclined holes 6 is formed (as shown in Figure 2 (b)), the area of the opening area of the multi-row inclined holes is 60% to 120% of the projected area of the downcomer bottom hole 5 on the tray 1, and the multi-row inclined holes The opening rate of the hole opening area is 80% to 120% of the opening rate of the other bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com