Deep control system for multiple pollutants through wet static electricity and reinforced by pre-charging

A wet electrostatic, deep control technology, applied in electrostatic separation, electrostatic effect separation, external electrostatic separator, etc., can solve the problem that the pre-charging technology is not suitable for the application of wet electrostatic precipitator, etc., to overcome the corona suppression phenomenon, realize the Deep purification control, the effect of improving work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

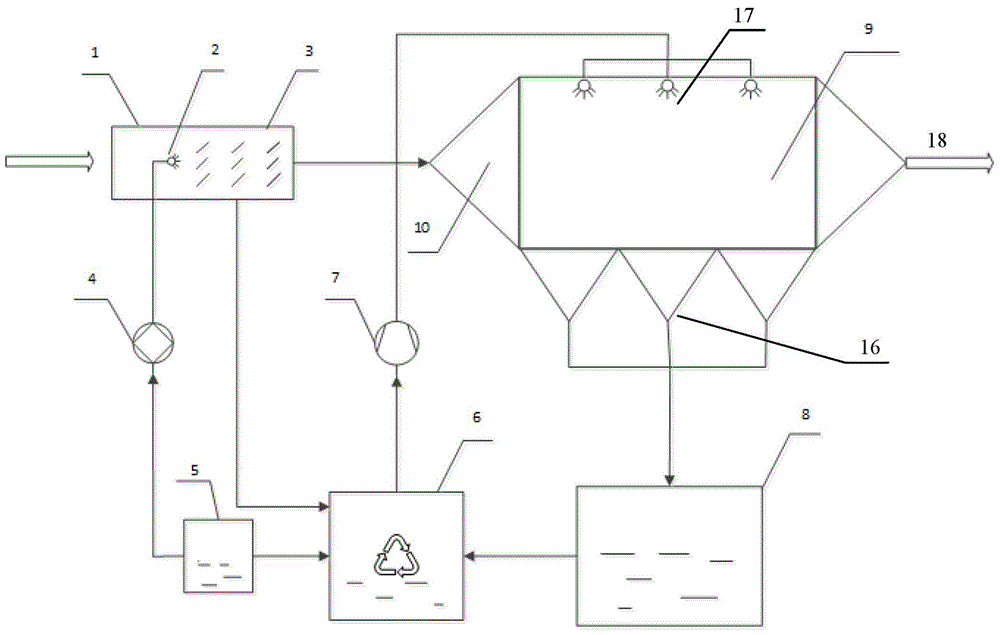

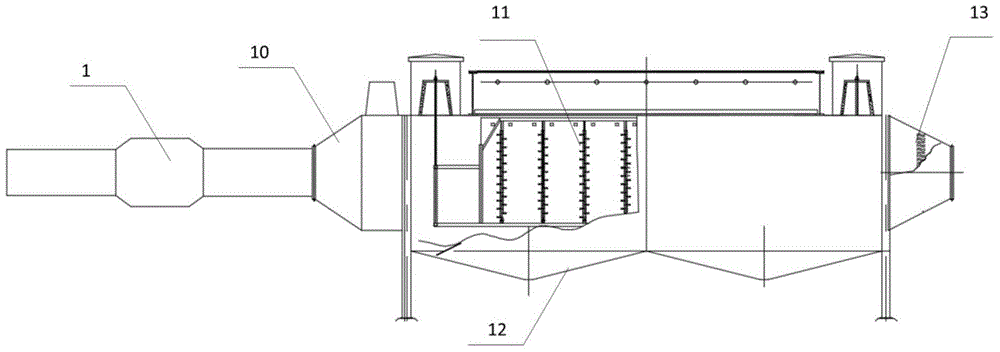

[0030] A pre-charged enhanced wet electrostatic multi-pollutant depth control system such as figure 1 , figure 2 and image 3 As shown, the system includes a lye atomizing mixer 1, a pre-charger 10 and a wet electrostatic reactor 9 connected in sequence, and the pre-charger is installed at the entrance of the wet electrostatic reactor.

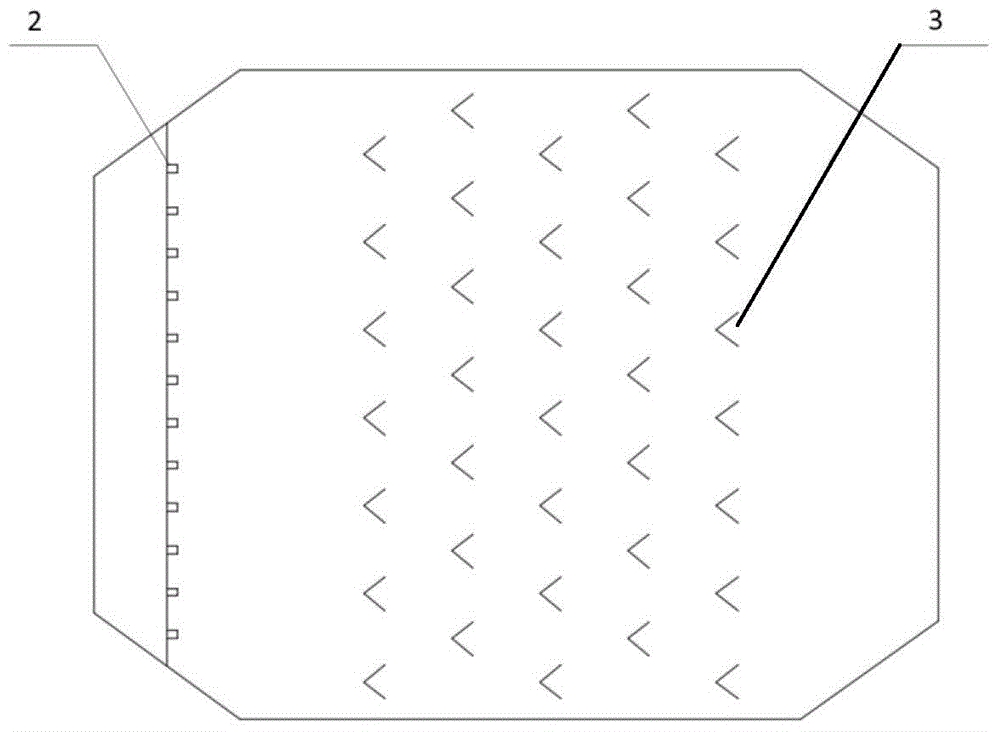

[0031] Such as image 3 As shown, a two-fluid atomizing nozzle 2 and a turbulent mixing plate 3 are installed inside the lye atomizing mixer. The two-fluid atomizing nozzle 2 is installed at the inlet of the lye atomizing mixer, and the turbulent mixing plate 3 is installed in the vertical direction inside the lye atomizing mixer. , same as "<" shape. The two-fluid atomizing nozzles are arranged in a staggered arrangement. When the atomization angle is 60°, the distance between the nozzles is 200mm.

[0032] The wet electrostatic reactor includes a corona electrode 11, a dust collector plate, a spray device 17, a circulating water system...

Embodiment 2

[0041] The concrete scheme of this embodiment is the same as embodiment 1, and the difference is:

[0042] The pre-charger includes a layer of airflow uniform distribution plate 19, and a row of corona pole lines are respectively arranged on both sides of the airflow uniform distribution plate, and the corona pole lines and the airflow uniform distribution plate are arranged at intervals.

[0043] The two-fluid atomizing nozzles in the lye atomizing mixer are arranged in series, and when the atomizing angle is 120°, the distance between the nozzles is 300mm.

[0044] The airflow uniform distribution plate of the pre-loading appliance is the anode plate, which is made of 316L stainless steel plate, with circular holes with a diameter of 30mm uniformly distributed, and a layer of airflow uniform distribution plate with an opening rate of 35%.

[0045] at 15,000Nm 3 Under the rated working condition of / h, the smoke and dust inlet concentration is 50-100mg / m 3 , entry SO 2 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com