High-pass flexible bionic dynamic membrane assembly and its production method and uses

A dynamic membrane and membrane module technology, applied in the fields of environment, biology and chemical industry, can solve problems such as membrane fouling, and achieve the effect of wide source, low cost and increase of fixed investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

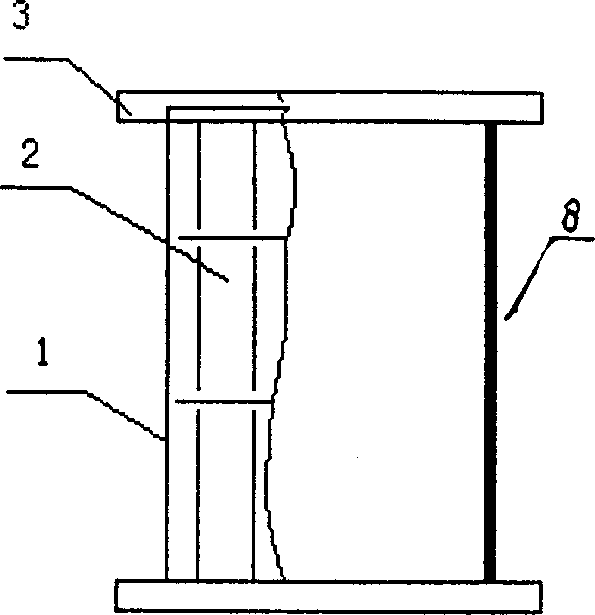

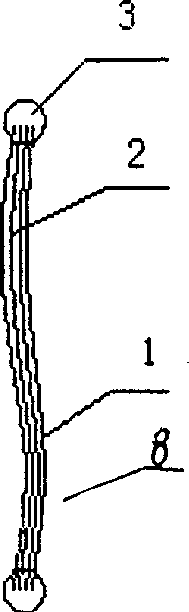

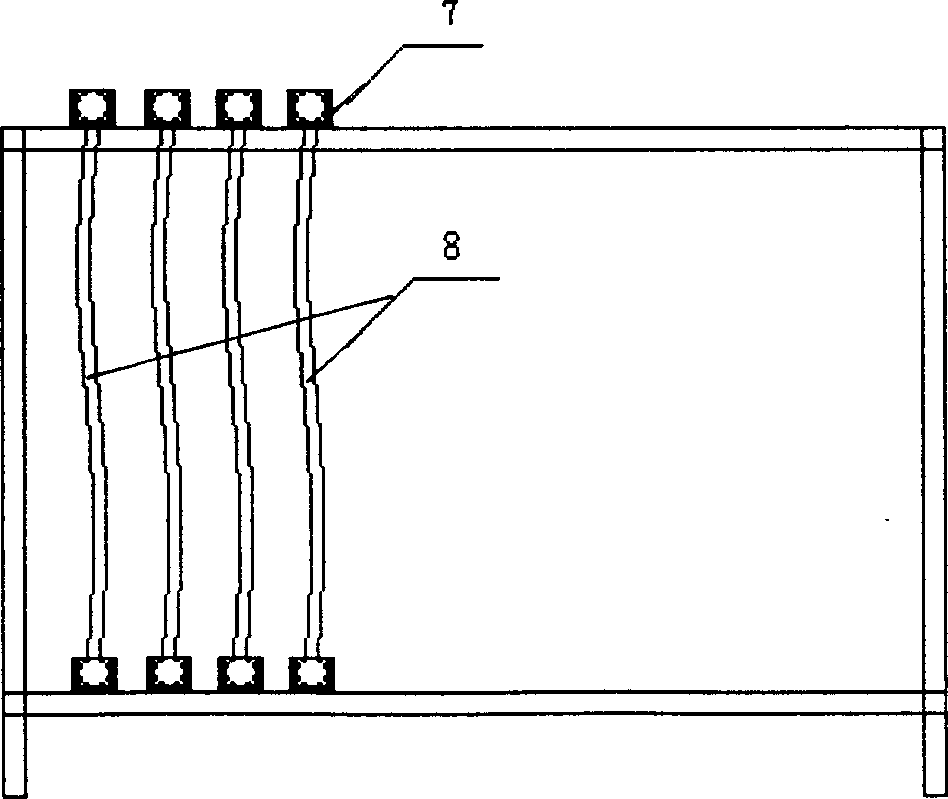

Image

Examples

Embodiment 1

[0027] Example 1: Choose 200-mesh and 300-mesh nylon screen as the base material to make a 1000×500mm membrane module, soak it in the collagen solution, add 0.5% chromium-aldehyde modifier, the reaction temperature is 30°C, and the reaction time is 2 hours, the water collecting pipe is 20mm PVC pipe. The membrane module of the present invention is used for the treatment of domestic sewage. The operating parameters of the biochemical reactor are as follows: influent COD 150-380mg / L, hydraulic retention time (HRT) 6h, activated sludge concentration 6.0-8.0g / L, powdered activated carbon dosing The dosage is 0.1%, the gas-water ratio is 20-30:1, the dissolved oxygen concentration (DO) is 2.0-4.0mg / L, the reaction temperature is 22-30°C, and the daily processing capacity is 5 tons. Control membrane flux 30L / m 2 ·h, continuous water outlet, the membrane pressure remains stable at -0.02MPa. The water quality of the effluent passing through the membrane module is as follows: COD<20m...

Embodiment 2

[0028] Embodiment 2: select 100 mesh screen mesh and 200 mesh nylon mesh as base materials, make 800 * 400mm membrane module, soak in collagen solution, add 1.5% chromium-aldehyde modifier, reaction temperature 40 ℃, reaction time 4 hours, the water collecting pipe is 20mm PVC pipe. The membrane module of the present invention is used for the treatment of printing and dyeing wastewater. The operating parameters of the biochemical reactor are as follows: the influent is hydrolyzed acidified wastewater, COD900-1500mg / L, chromaticity about 50 times, hydraulic retention time (HRT) 15h, activated sludge concentration 6.5~8.0g / L, the dosage of powdered activated carbon is 0.6%, and the daily processing capacity is 2.5 tons. Control membrane flux 20L / m 2 h, the membrane pressure is kept stable at -0.02MPa. The water quality of the effluent passing through the membrane module is as follows: COD<100mg / L, SS is zero, and the chromaticity is 3 times. The membrane module of the present...

Embodiment 3

[0029] Example 3: Select 80-mesh nylon mesh and filter cloth as the base material to make a membrane module with a size of 1100 × 600mm, soak it in the collagen solution, add 3.0% chromium-aldehyde modifier, the reaction temperature is 35 ° C, and the reaction time is 6 hours , The water collecting pipe is a 20mm rubber hose. The membrane module of the present invention is used for the treatment of terephthalic acid (PTA) wastewater, and the operating parameters of the biochemical reactor are as follows: terephthalic acid (PTA) production wastewater mainly contains terephthalic acid, acetic acid, methyl acetate, etc. Water COD4000±1000mg / L, TA1400±100mg / L, hydraulic retention time (HRT) 30h, TA degrading strain concentration 2.0-4.0g / L, powdered activated carbon dosage 1.0%, daily treatment capacity 1.6 tons. Control membrane flux 18L / m 2 ·h, continuous water discharge, the membrane pressure is kept stable at -0.02~-0.03MPa. The water quality of the effluent passing through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com