Production method and production system of container door panel

A technology for container door panels and production systems, which can be applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of reduced container door panel processing costs, low production efficiency, and increased human resource costs. Small area and the effect of reducing hoisting turnover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

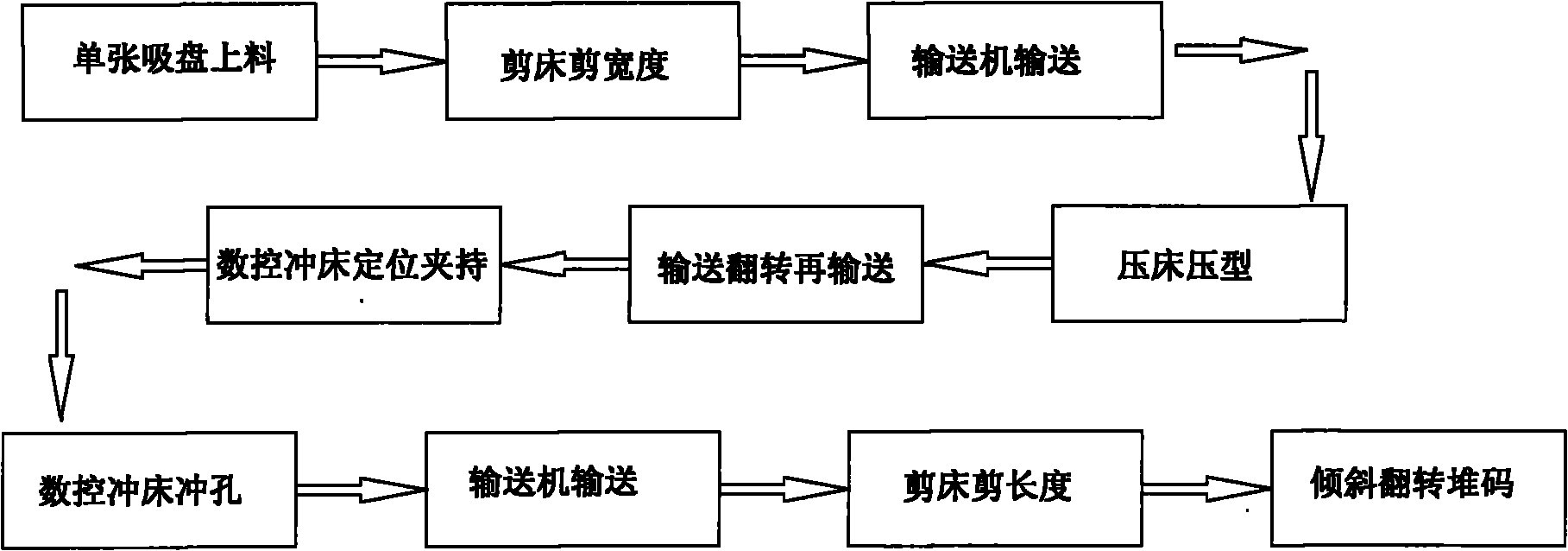

[0024] The production method of the container door panel of the present invention is that the sheet material is automatically or semi-automatically once passed through equipment such as shearing machine cutting width device, press, punching machine, shearing machine cutting length device, stacking, etc. to complete cutting width, pressing, punching, shearing, etc. Length, stacking and other processes, and finally finished products. The sheet is automatically conveyed between the various equipment through the assembly line, which saves the trouble of frequent hoisting by the machine and improves the production efficiency.

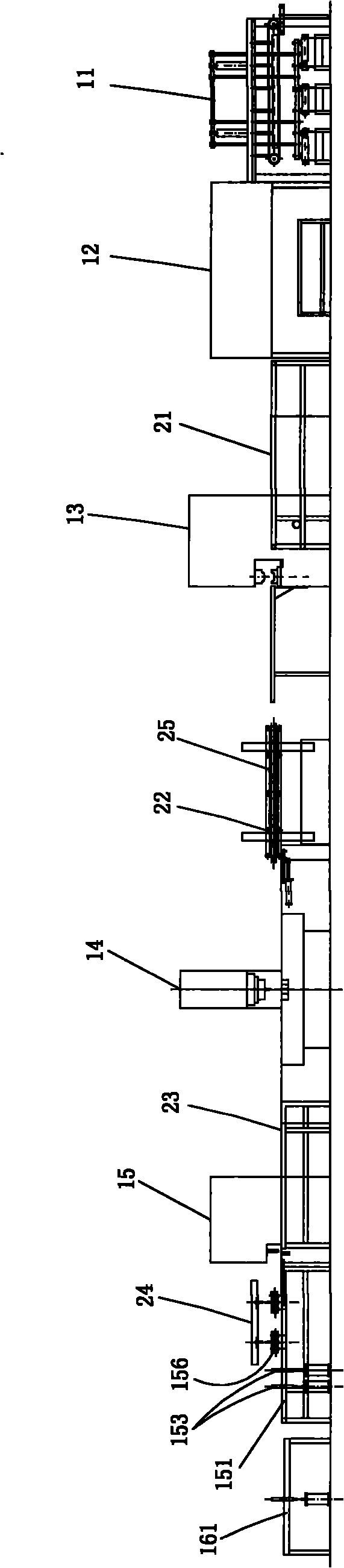

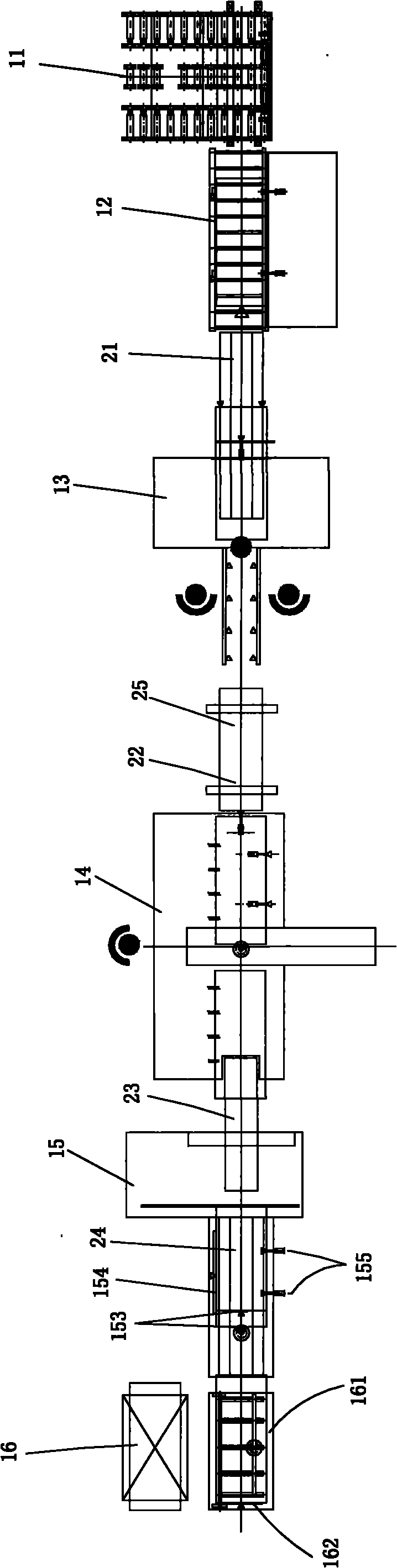

[0025] In order to realize the above production method, the present embodiment provides a door panel production system, such as figure 1 As shown, the production system includes: automatic feeding device 11, shear width device 12, press 13, numerical control punch 14, shear length device 15 and door panel stacking platform 16 and other equipment, in the shea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com