Process for recovering heavy metallic salt and inorganic acid in pickling waste liquid

A heavy metal salt and acid recovery technology, which is applied in chemical instruments and methods, semi-permeable membrane separation, permeation/dialysis water/sewage treatment, etc., can solve incomplete resource recovery, reduce membrane service life, increase treatment costs, etc. problem, to achieve the effect of increasing the economic effect of the enterprise, increasing the processing cost, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

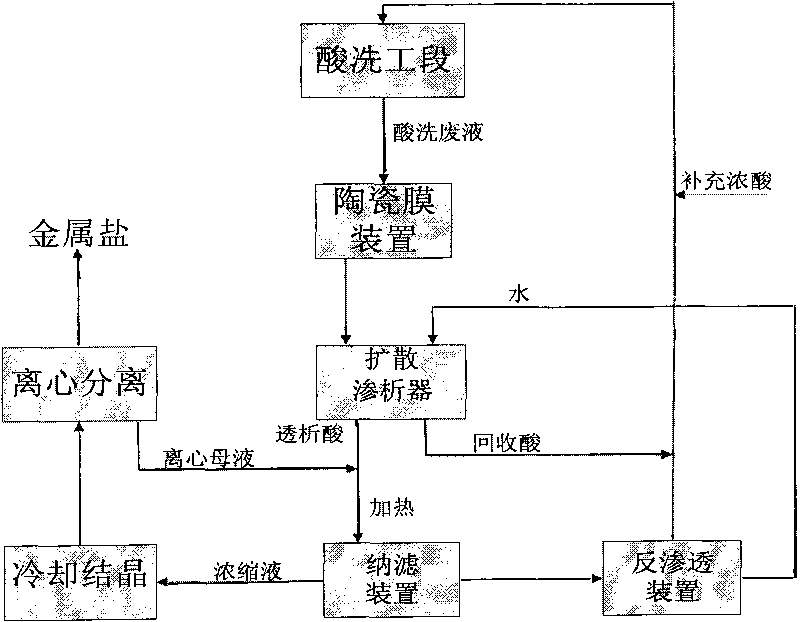

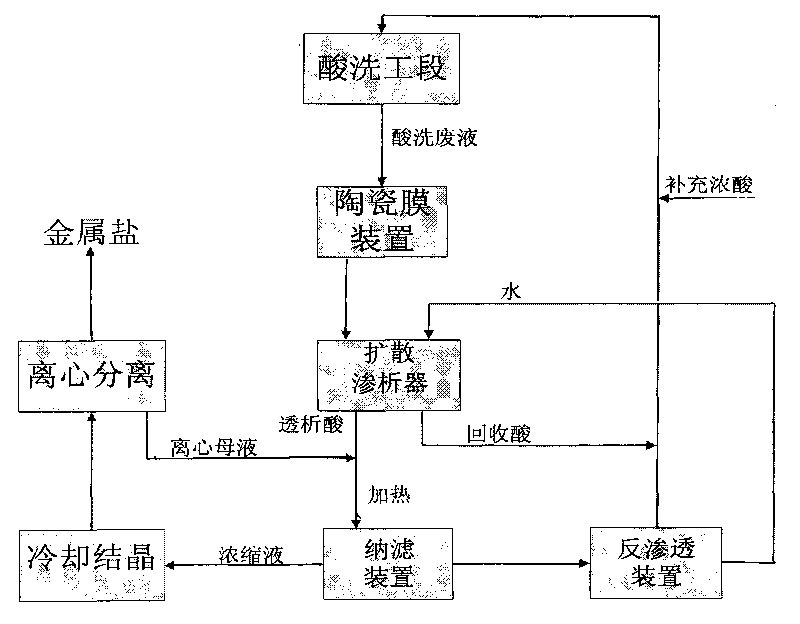

[0025] Below in conjunction with accompanying drawing and example the present invention will be further described

[0026] Such as figure 1 Shown, treatment of hot-rolled stainless steel sulfuric acid deoxidized layer pickling wastewater. Among them, sulfuric acid cleaning waste liquid contains FeSO 4 60g / L, sulfuric acid 200g / L. Its method is:

[0027] Step 1: Use a corrosion-resistant pump to drive the waste acid into the alumina ceramic device (Jiangsu Jiuwu High-Tech Co., Ltd. ceramic membrane complete set of equipment, the alumina ceramic membrane pore size is 0.05μm) for filtration, and control the transmembrane pressure to 0.2MPa. The membrane surface velocity is 2m / s. Remove suspended solids to reduce the suspended solids of waste acid to 20NTU.

[0028] Step 2: The permeate of the ceramic membrane device passes through the dialysis side of the diffusion dialysis device (Diffusion dialysis device of Nanjing Jiusi High-tech Co., Ltd., the ion exchange membrane adop...

Embodiment 2

[0033] Such as figure 1 As shown, the aluminum surface cleaning waste liquid contains Al 2 (SO 4 ) 3 150g / L, sulfuric acid 250g / L. Its method is:

[0034] The first step: pump the waste acid into the ceramic membrane device (Jiangsu Jiuwu High-tech Co., Ltd. ceramic membrane complete set of equipment, the pore size of the zirconia ceramic membrane is 0.2 μm) for filtration through a corrosion-resistant pump, and control the transmembrane pressure to 0.4MPa. The membrane surface velocity is 3m / s. Remove the suspended solids to reduce the suspended solids of the waste acid to 10NTU.

[0035] Step 2: The permeate of the ceramic membrane device passes through the dialysis side of the diffusion dialysis device (Diffusion dialysis device of Nanjing Jiusi High-tech Co., Ltd., the ion exchange membrane adopts Japan Asahi Glass DSV anion exchange membrane), and at the same time, the water is passed into the recovery side. The permeate and water of the membrane device are in a rat...

Embodiment 3

[0040] Such as figure 1 As shown, the treatment of stainless steel passivation waste liquid contains 30g / L of iron ions, 140g / L of nitric acid, and 80g / L of hydrofluoric acid. Its method is:

[0041] The first step: pump the waste acid into the ceramic membrane device (Jiangsu Jiuwu High-tech Co., Ltd. ceramic membrane complete set of equipment, the pore size of the alumina ceramic membrane is 0.5 μm) for filtration through a corrosion-resistant pump, and control the transmembrane pressure to 0.5 MPa. The membrane surface velocity is 2.5m / s. Remove suspended solids to reduce the suspended solids of waste acid to 15NTU.

[0042] Step 2: The ceramic membrane permeate passes through the dialysis side of the diffusion dialysis device (Nanjing Jiusi High-tech Co., Ltd. diffusion dialysis device, the ion exchange membrane adopts the Japanese Asahi Glass APS anion exchange membrane), and at the same time passes the water into the recovery side, and the ceramic membrane device Perm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com