Magnalium composite board and method for producing the same

The technology of a composite sheet and a manufacturing method, which is applied to the composite sheet and its manufacturing field, can solve the problems of low peeling strength and poor shock resistance of the easily disintegrated sheet and the composite sheet, and achieves the effects of not easy to crack, light weight and good durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

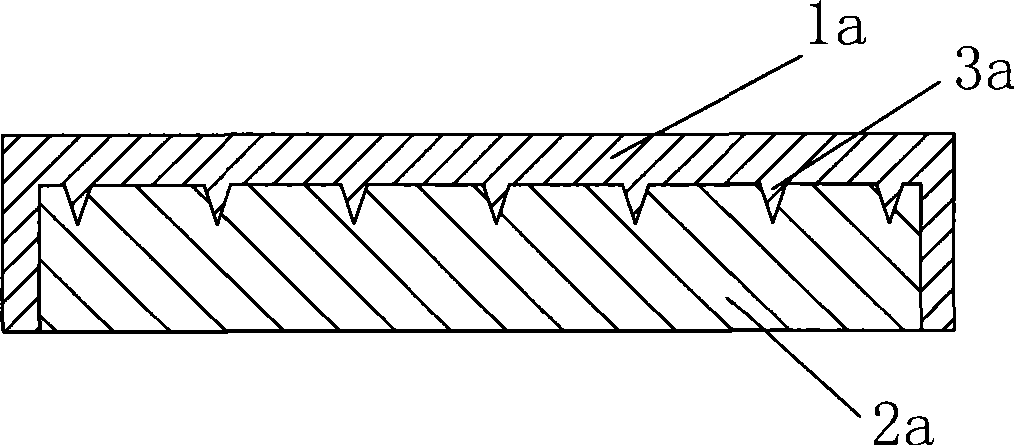

[0034] Such as figure 1 As shown, the magnesium-aluminum composite plate described in this embodiment includes a layer of magnesium or magnesium alloy plate and a layer of aluminum or aluminum alloy plate, the upper surface layer is aluminum or aluminum alloy plate 1a, the thickness is 2-10mm, and the lower layer is magnesium or aluminum alloy plate 1a The magnesium alloy plate 2a, wherein the aluminum or aluminum alloy plate 1a has a ∏ structure, wraps around the lower magnesium or magnesium alloy plate 2a, and the joint surface between the two layers is a sawtooth structure 3a to increase the joint strength.

Embodiment 2

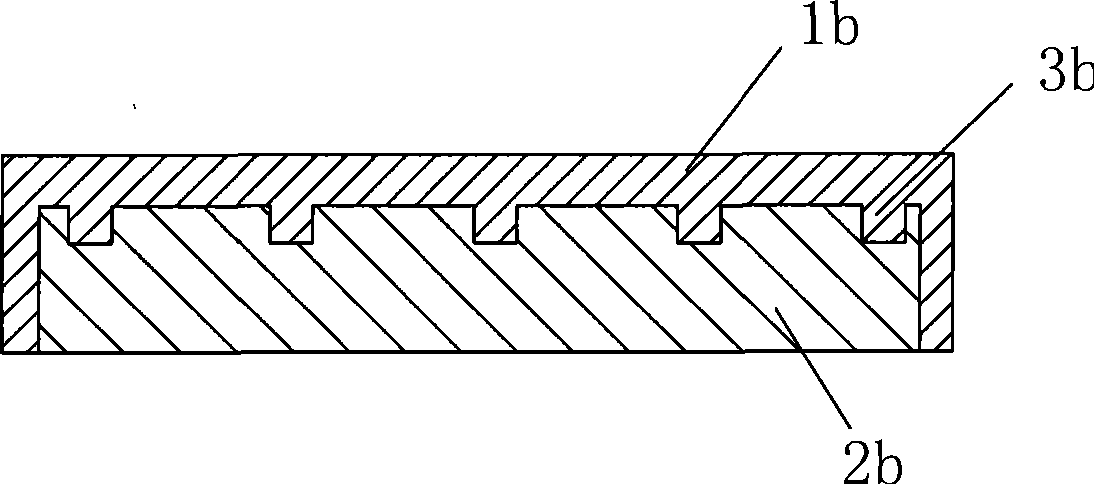

[0036] Such as figure 2 As shown, the magnesium-aluminum composite plate described in this embodiment includes a layer of magnesium or magnesium alloy plate and a layer of aluminum or aluminum alloy plate, the upper surface layer is aluminum or aluminum alloy plate 1b, the thickness is 10mm, and the lower layer is magnesium or magnesium alloy plate The plate 2b, wherein the aluminum or aluminum alloy plate 1b has a ∏ structure, wraps around the lower layer of magnesium or magnesium alloy plate 2b, and the zigzag structure of the bonding surface between the two layers is a concave-convex structure formed by bumps 3b.

Embodiment 3

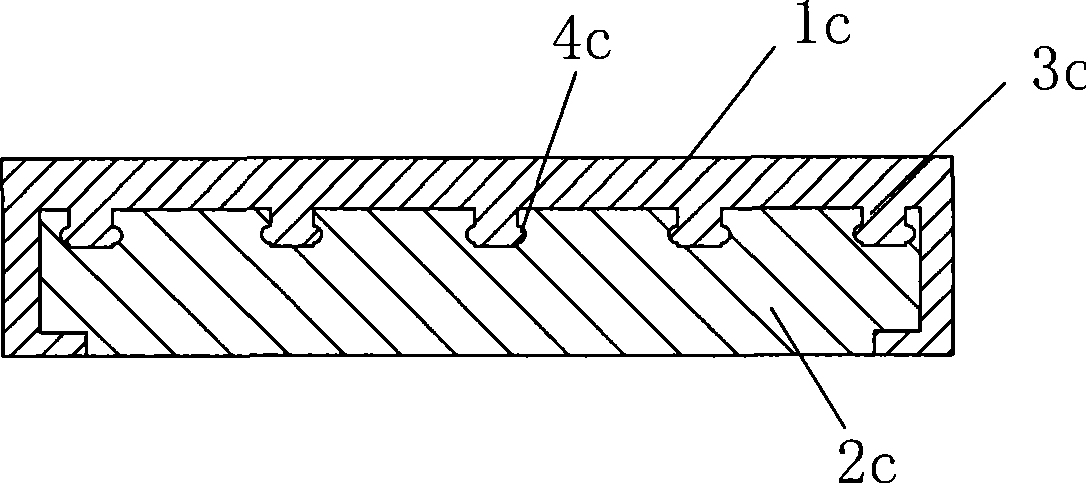

[0038] Such as image 3 As shown, the magnesium-aluminum composite plate described in this embodiment includes a layer of magnesium or magnesium alloy plate and a layer of aluminum or aluminum alloy plate, the upper surface layer is aluminum or aluminum alloy plate 1c, the thickness is 10mm, and can also be more than 10mm, The lower layer is a magnesium or magnesium alloy plate 2c, wherein the aluminum or aluminum alloy plate 1c wraps the lower magnesium or magnesium alloy plate 2c and the edge of the lower surface together, and the sawtooth structure of the bonding surface between the two layers is formed by bumps 3c Concavo-convex structure, between the concavo-convex combination, there is a protrusion 4c which increases the bonding strength.

[0039] The magnesium-aluminum composite plate of the present invention is not only the above three structures, but also a combination of the above three structures, and the sawtooth structure can also be a threaded column or threaded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com