Double-stage oxidation treatment process for weak-phosphorus flammable sludge under synergistic effect of ultrasonic aeration

A synergistic and oxidation treatment technology, which is applied in the direction of oxidation treatment of sludge, water/sludge/sewage treatment, water pollutants, etc., can solve the problem of high phosphorus content in phosphorus mud, damage to the surrounding ecological environment, and difficulty in recycling And other problems, to achieve the effect of shortening the processing time, processing thoroughly, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

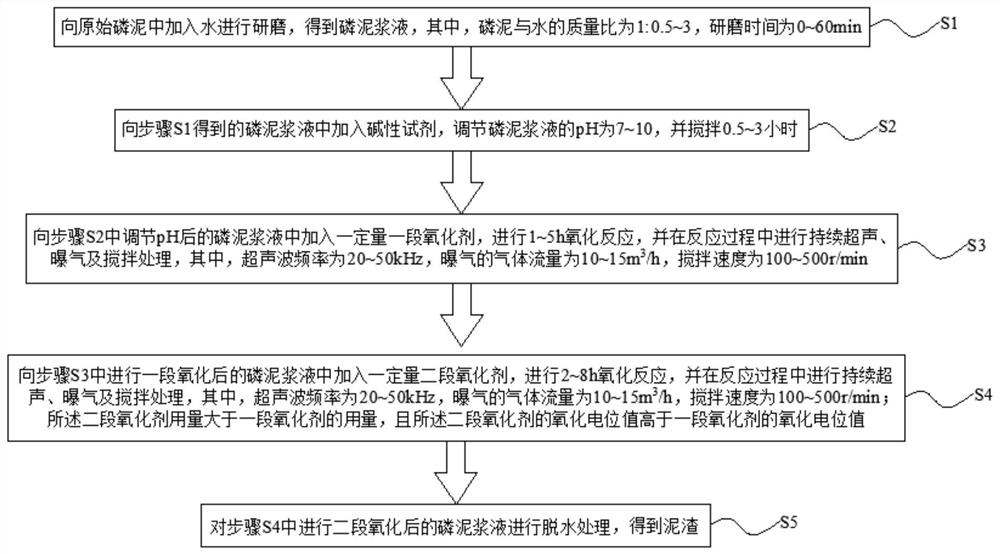

[0029] A dual-stage oxidation treatment process for weak phosphorus flammable sludge proposed in this embodiment, which includes the following steps:

[0030] S1: Add water to the original phosphorus mud for grinding to obtain phosphorus mud slurry, wherein the mass ratio of phosphorus mud to water is 1:0.5~3, and the grinding time is 0~60min;

[0031] S2: adding an alkaline reagent to the phosphorus mud slurry obtained in step S1, adjusting the pH of the phosphorus mud slurry to 7-10, and stirring for 0.5-3 hours;

[0032] S3: Add a certain amount of oxidant to the phosphorus mud slurry after pH adjustment in step S2, carry out oxidation reaction for 1-5 hours, and carry out continuous ultrasonication, aeration and stirring treatment during the reaction process, wherein the ultrasonic frequency is 20-50kHz , the gas flow rate of aeration is 10~15m 3 / h, the stirring speed is 100~500r / min;

[0033] S4: Add a certain amount of second-stage oxidant to the phosphorus mud slurry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com