Easy-welding electrode connection piece blank treatment process

A processing technology and connecting piece technology, applied in the direction of circuits, electrical components, battery pack components, etc., can solve the problems of affecting the welding effect, easy oxidation of materials, difficult welding, etc., to achieve easy welding, improve safety, and reduce failure rates. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

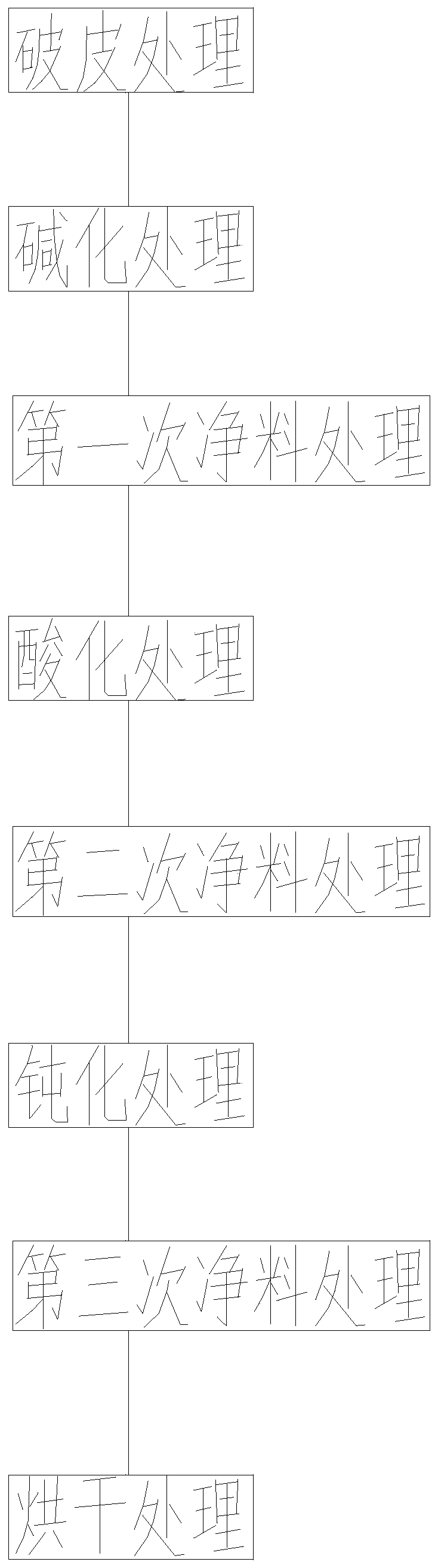

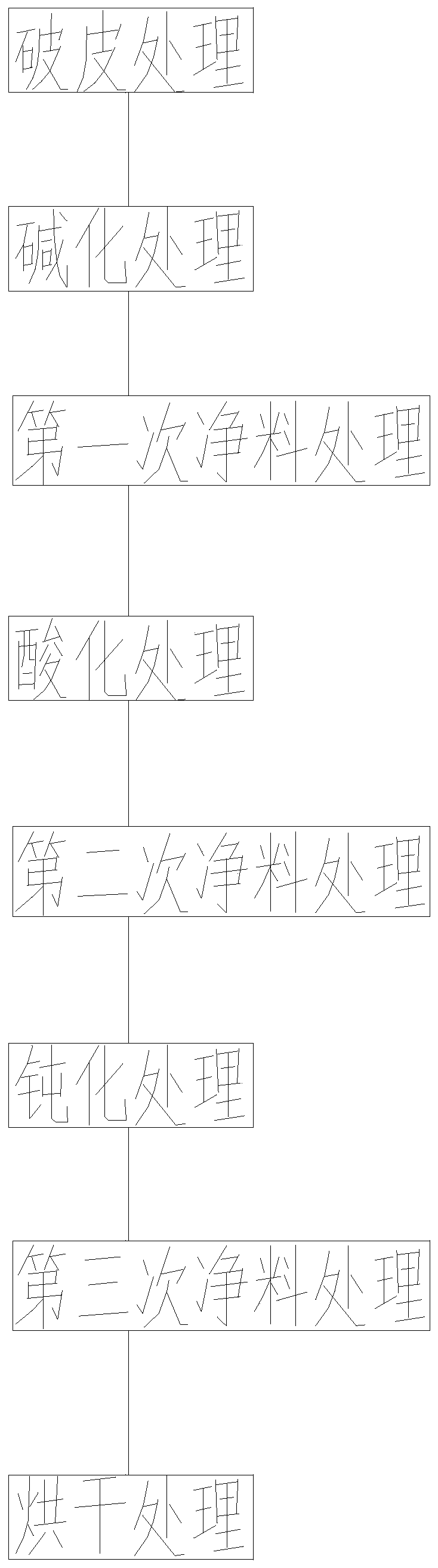

[0027] refer to figure 1 , an easy-to-weld electrode connecting sheet blank processing process of the present invention, comprising the following steps: S2 alkalization treatment, using NaHO with a purity of 99%-99.6% and water to form a NaHO solution in a ratio of 1:10 to clean the material; During cleaning, the temperature is controlled at 50°C to 55°C; for the first clean material treatment of S3, clean the material with pure water at room temperature; for acidification treatment of S4, use nitric acid with a purity of 99.2%-99.7% and water at a ratio of 1:9 Mix it into HNO3 solution to clean the material; S5 the second clean material treatment, clean the material with pure water at room temperature; S6 passivation treatment, use chrome-free environmental protection alodine and water in a ratio of 1.5:10 to make a Lodin solution to clean the material; the treatment time of the material in the alodine solution is controlled at 20 to 22 minutes; the third clean material treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com