A high-hardness zinc-copper-aluminum alloy

An aluminum alloy and high-hardness technology, which is applied in the field of high-hardness zinc-copper-aluminum alloys, can solve the problems of affecting alloy performance, large raw material burning loss, and reduced impact toughness at room temperature, so as to improve hardness and wear resistance and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0022] 1. Preparation of Zn-Cu-Al alloy 33.3Zn-33.3Cu-33.3Al with equal mass ratio

[0023] First, put 60g of industrial pure zinc and 120g of Al-50Cu master alloy into a graphite crucible for heating and smelting in a well-type electric furnace. The smelting temperature is 750°C. After complete melting, stir and let stand for 5 minutes. Add refining agent C. 2 Cl 6 , the amount of refining agent added is 0.3% of the total charge, and then allowed to stand for 30 minutes for slag removal and casting.

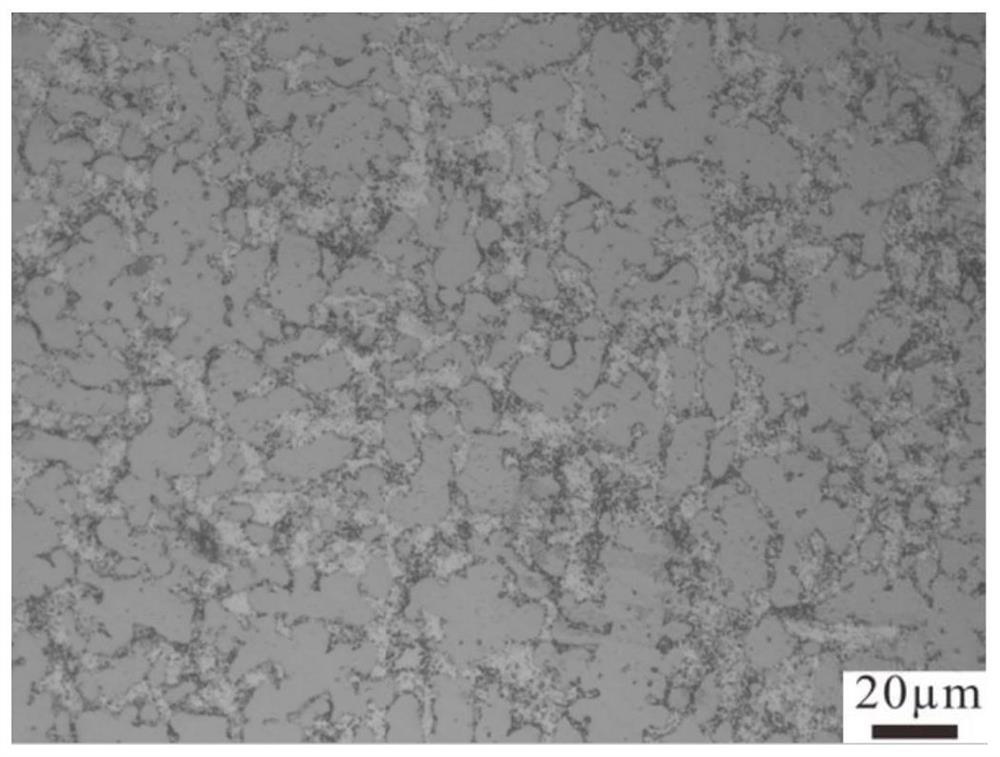

[0024] figure 1 It is the microstructure of zinc-copper-aluminum alloy with equal mass ratio, and the microstructure of the alloy is composed of Zn phase, Al phase, Al 2 It is composed of Cu phase and Al4.2Cu3.2Zn0.7. It can be seen from the microstructure that there is no obvious segregation of alloy elements in the microstructure of the alloy, and there is no need to refine the grain size of the alloy by heat treatment after casting. The medium-coarse phase is the matrix ph...

Embodiment example 2

[0028] 1. Preparation of 32Zn-32Cu-36Al alloy

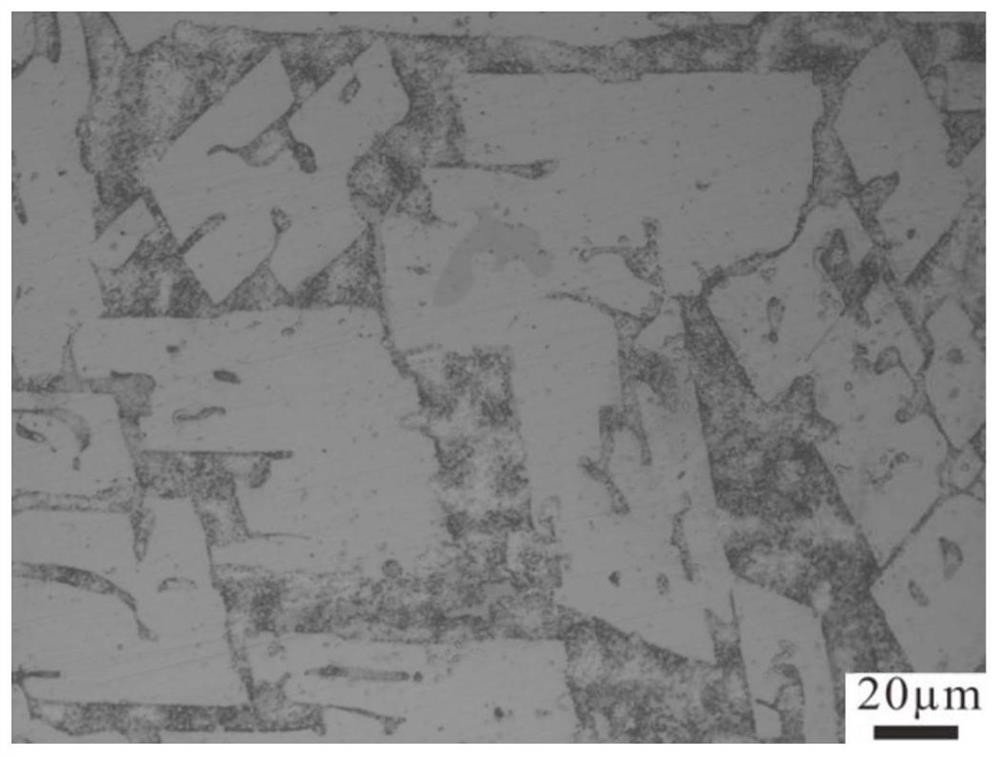

[0029] First, put 64g of industrial pure zinc, 8g of industrial pure aluminum and 128g of Al-50Cu into a graphite crucible for heating and smelting in a well-type electric furnace. The smelting temperature is 750℃. Refining agent, let stand for another 30 minutes, carry out slag removal and casting, and naturally cool to room temperature after casting. The 32Zn-32Cu-36Al alloy of the present invention is obtained. figure 2 It is the microstructure of 32Zn-32Cu-36Al alloy.

[0030] 2. Mechanical properties of 32Zn-32Cu-36Al alloy

[0031] The impact specimen is a cylindrical specimen, Figure 5 The dimensions of the die-cast zinc alloy impact specimen. The mechanical properties of 32Zn-32Cu-36Al alloy samples were tested, the room temperature hardness was 90HRB (Hv274.5), the room temperature impact toughness did not change much, and the room temperature impact toughness was 0.88J / cm 2 .

Embodiment example 3

[0033] 1. Preparation of 36Zn-32Cu-32Al alloy

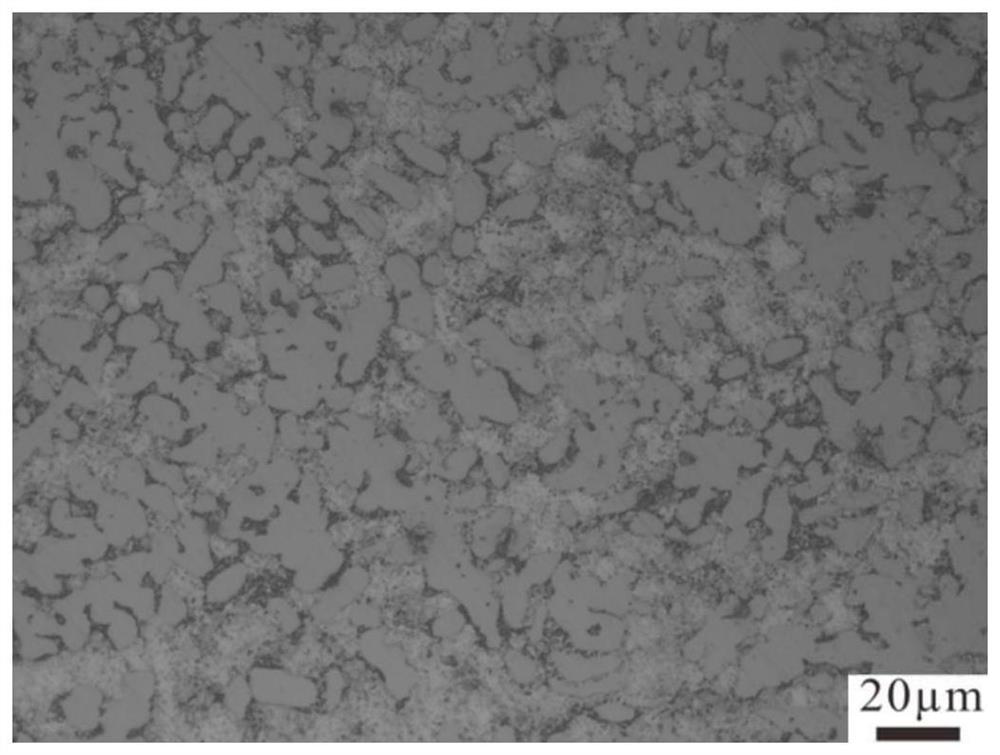

[0034] First, put 72g of industrial pure zinc and 128g of Al-50Cu into a graphite crucible for heating and smelting in a pit electric furnace. The smelting temperature is 750°C. After complete melting, stir and let stand for 5 minutes. Set aside for 30 minutes, carry out slag removal and casting, and naturally cool to room temperature after casting. The 36Zn-32Cu-32Al alloy of the present invention is obtained. image 3 It is the microstructure of 36Zn-32Cu-32Al alloy.

[0035] 2. Mechanical properties of 36Zn-32Cu-32Al alloy

[0036] The impact specimen is a cylindrical specimen, Figure 5 The dimensions of the die-cast zinc alloy impact specimen. The mechanical properties of 36Zn-32Cu-32Al alloy samples were tested, the room temperature hardness was 92HRB (Hv284.8), the room temperature impact toughness did not change much, and the room temperature impact toughness was 1.85J / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com