Method for preparing metal-organic framework material HKUST-1 from copper-containing industrial wastewater

A HKUST-1, industrial wastewater technology, applied in the field of wastewater utilization, can solve the problems of non-reusable use, high cost, expensive copper salt precursors and organic solvents, and achieve the effect of reducing environmental pollution and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

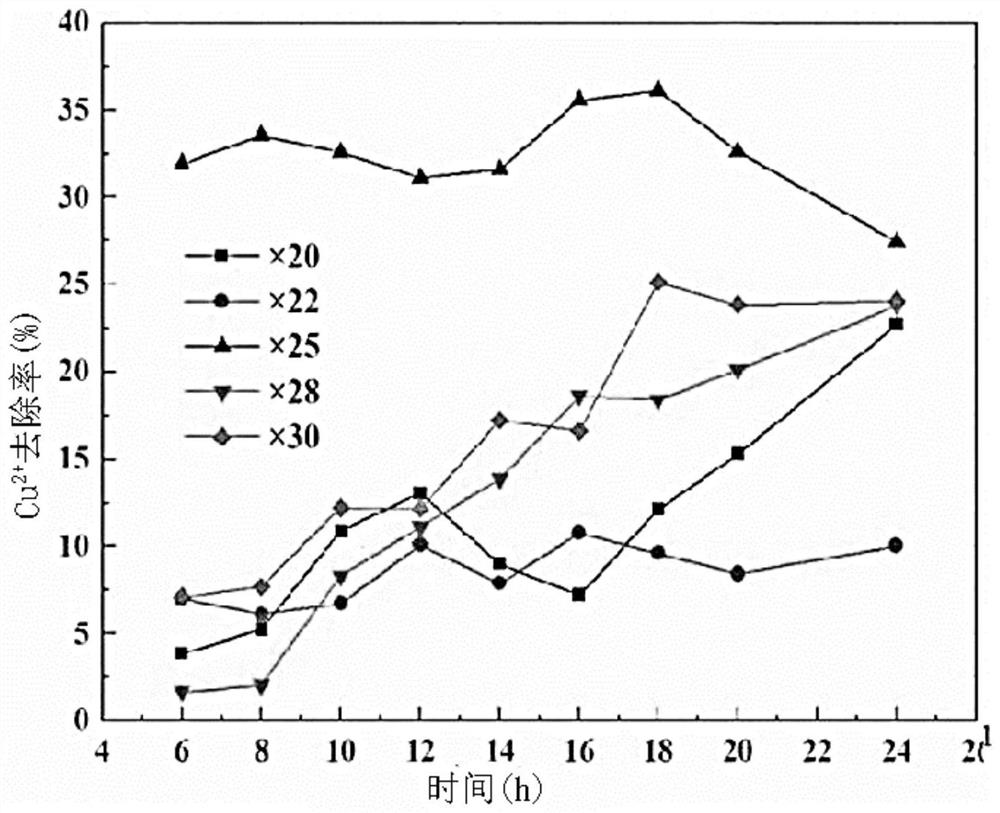

[0055] (1) Get the copper-containing industrial waste water of Ningbo factory, filter, after removing solid residue, test the content of each metal ion, waste water pH value and COD value wherein, wherein, Cu 2+ 213.7g / L, Co 2+ 0.01584g / L, Ni + 1.144g / L, Zn 2+ 0.3154g / L, Fe 2+ / 3+ 3.634g / L, Na + 98.3g / L, Mg 2+ 0.1034g / L and Cr 3+ / 6+ 0.055g / L; pH value is -0.87; COD value is 2×10 -3 g / L;

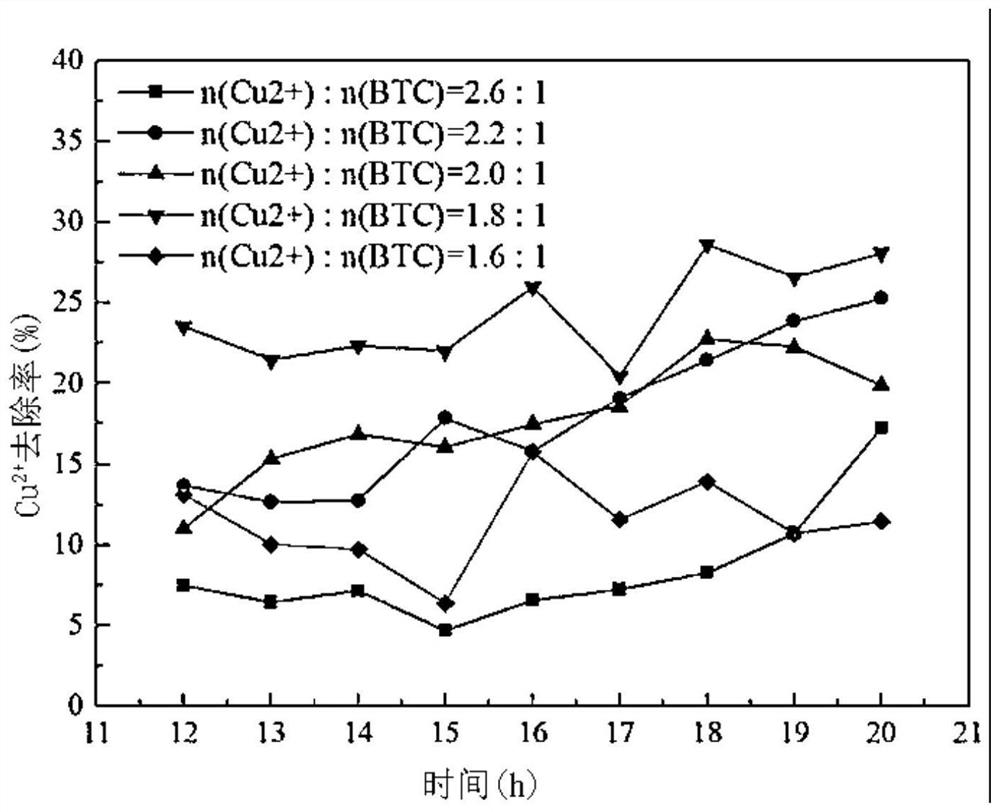

[0056] (2) Add 152mL deionized water to 8mL copper-containing industrial wastewater and dilute 20 times (after dilution, Cu 2+ 10.685g / L, Co 2+ 0.000792g / L, Ni + 0.0572g / L, Zn 2+ 0.01577g / L, Fe 2+ / 3+ 0.1817g / L, Na + 4.915g / L, Mg 2+ 0.00517g / L and Cr 3+ / 6+ 0.00275g / L; pH value is 0.43; COD value is 0.1×10 -3 g / L) is placed in the beaker, then add 2.75g trimesic acid (the ratio of the amount of copper ion in the copper-containing industrial wastewater to the amount of trimesic acid is 2.0:1), the beaker is placed in a constant temperature stirrer Above, control the rotational spe...

Embodiment 2

[0059] Add 168mL deionized water to dilute 22 times in 8mL copper-containing industrial waste water in embodiment 1 (after dilution Cu 2+ 9.714g / L, Co 2+ 0.00072g / L, Ni + 0.052g / L, Zn 2+ 0.01434g / L, Fe 2+ / 3+ 0.1652g / L, Na + 4.468g / L, Mg 2+ 0.0047g / L and Cr 3+ / 6+ 0.0025g / L; pH value is 0.47; COD value is 0.09×10 -3 g / L), other parameters are the same as in Example 1.

Embodiment 3

[0061] Add 192mL deionized water to dilute 25 times in 8mL copper-containing industrial waste water in embodiment 1 (after dilution Cu 2+ 8.548g / L, Co 2+ 0.0006g / L, Ni + 0.046g / L, Zn 2+ 0.0126g / L, Fe 2+ / 3+ 0.1454g / L, Na + 3.932g / L, Mg 2 + 0.0041g / L and Cr 3+ / 6+ 0.0022g / L; pH value is 0.53; COD value is 0.08×10 -3 g / L), other parameters are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com