Process for treating wastewater in copper industry by using polymeric ferric sulfate

A polymeric ferric sulfate and composite treatment technology, applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem of low copper removal efficiency and achieve high removal rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

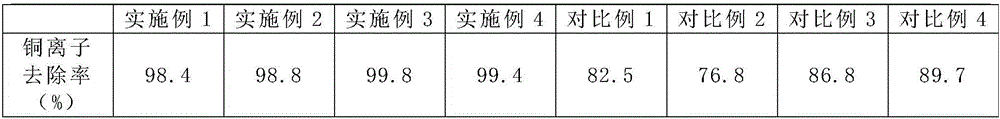

Examples

Embodiment 1

[0015] First, the flocculant polyferric sulfate and bentonite are mixed to form a composite treatment agent; then the prepared composite treatment agent is added to the copper industry wastewater, stirred and reacted for 5 minutes, and precipitated after the reaction is completed for 5 minutes, and finally solid-liquid separation is carried out. The flocculant polymeric ferric sulfate is a solution with a mass fraction of polymeric ferric sulfate of 5%, and the mass ratio of the bentonite to the polymeric ferric sulfate is 4:10. The mass-volume ratio of polyferric sulfate to the copper wastewater in the composite treatment agent is 10 mg / L. The pH of the wastewater was adjusted to 6 before the composite treatment agent was added to the wastewater from the copper industry. Finally, the treated water is taken for testing.

Embodiment 2

[0017] First, the flocculant polymerized ferric sulfate and bentonite are mixed to form a composite treatment agent; then the prepared composite treatment agent is added to the copper industry wastewater, stirred and reacted for 1 minute, and precipitated after the reaction is completed for 1 minute, and finally solid-liquid separation is carried out. The flocculant polymeric ferric sulfate is a solution with a mass fraction of polymeric ferric sulfate of 20%, and the mass ratio of the bentonite to the polymeric ferric sulfate is 1:10. The mass volume ratio of polyferric sulfate to the copper wastewater in the composite treatment agent is 30 mg / L. The pH of the wastewater was adjusted to 8 before the composite treatment agent was added to the wastewater from the copper industry. Finally, the treated water is taken for testing.

Embodiment 3

[0019] First, the flocculant polymerized ferric sulfate and bentonite are mixed to form a composite treatment agent; then the prepared composite treatment agent is added to the copper industry wastewater, stirred and reacted for 1 minute, and precipitated after the reaction is completed for 1 minute, and finally solid-liquid separation is carried out. The flocculant polymeric ferric sulfate is a solution with a mass fraction of polymeric ferric sulfate of 10%, and the mass ratio of the bentonite to the polymeric ferric sulfate is 1:5. The mass-volume ratio of polyferric sulfate to the copper wastewater in the composite treatment agent is 10 mg / L. The pH of the wastewater was adjusted to 7 before the composite treatment agent was added to the wastewater from the copper industry. Finally, the treated water is taken for testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com