Processing technology of high-purity copper product for space flight and aviation

A technology of aerospace and processing technology, applied in the field of high-purity copper processing, can solve the problems of high industrial production cost, no electrolyte purification treatment, etc., and achieve the effects of simple equipment, improved surface quality, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

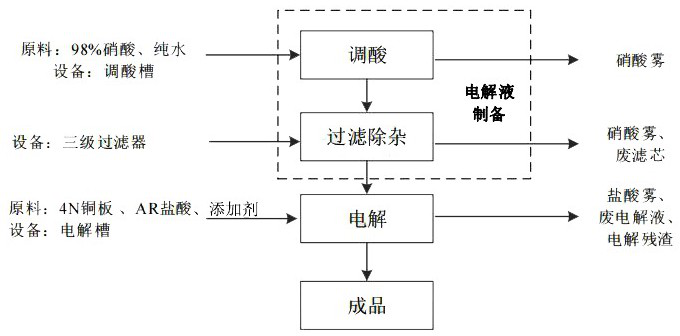

Image

Examples

Embodiment 2

[0033] In the present embodiment, a kind of processing technology of aerospace high-purity copper product comprises the following steps:

[0034] Step 1: acid adjustment, pump 68% nitric acid and pure water into the acid adjustment tank according to a certain ratio, adjust the pH value to 3, prepare nitric acid electrolyte, and then pump it into the liquid storage tank.

[0035] Step 2: filter to remove impurities, pass the pH-adjusted nitric acid electrolyte through a three-stage filter to remove impurities.

[0036] Step 3: Electrolysis. Use 4N high-purity copper plate as the anode plate and titanium plate as the cathode plate. First, wash off the oxide film on the surface of the anode plate and cathode plate with dilute hydrochloric acid, and put the cleaned anode plate and cathode plate into the electrolytic cell. And the filtered nitric acid electrolyte is pumped into the electrolytic cell.

[0037] To prepare an additive solution, bone glue, gelatin and thiourea were us...

Embodiment 3

[0042] In the present embodiment, a kind of processing technology of aerospace high-purity copper product comprises the following steps:

[0043] Step 1: acid adjustment, pump 68% nitric acid and pure water into the acid adjustment tank according to a certain ratio, adjust the pH value to 3, prepare nitric acid electrolyte, and then pump it into the liquid storage tank.

[0044] Step 2: filter to remove impurities, pass the pH-adjusted nitric acid electrolyte through a three-stage filter to remove impurities.

[0045] Step 3: Electrolysis. Use 4N high-purity copper plate as the anode plate and titanium plate as the cathode plate. First, wash off the oxide film on the surface of the anode plate and the cathode plate with dilute hydrochloric acid, and put the cleaned anode plate and cathode plate into the electrolytic cell. And the filtered nitric acid electrolyte is pumped into the electrolytic cell.

[0046] The additive solution was prepared, using bone glue, gelatin and thi...

Embodiment 4

[0051] In the present embodiment, a kind of processing technology of aerospace high-purity copper product comprises the following steps:

[0052] Step 1: acid adjustment, pump 68% nitric acid and pure water into the acid adjustment tank according to a certain ratio, adjust the pH value to 3, prepare nitric acid electrolyte, and then pump it into the liquid storage tank.

[0053] Step 2: filter to remove impurities, pass the pH-adjusted nitric acid electrolyte through a three-stage filter to remove impurities.

[0054] Step 3: Electrolysis. Use 4N high-purity copper plate as the anode plate and titanium plate as the cathode plate. First, wash off the oxide film on the surface of the anode plate and the cathode plate with dilute hydrochloric acid, and put the cleaned anode plate and cathode plate into the electrolytic cell. And the filtered nitric acid electrolyte is pumped into the electrolytic cell.

[0055] The additive solution was prepared, using bone glue, gelatin and thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com