Purifying device for copper-industry wastewater and waste gas

A technology for purifying equipment and sewage, applied in biological water/sewage treatment, water/sludge/sewage treatment, gas treatment, etc. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

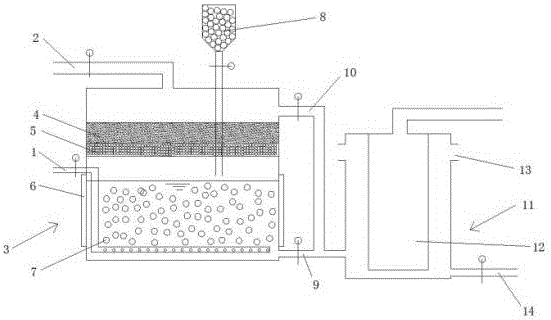

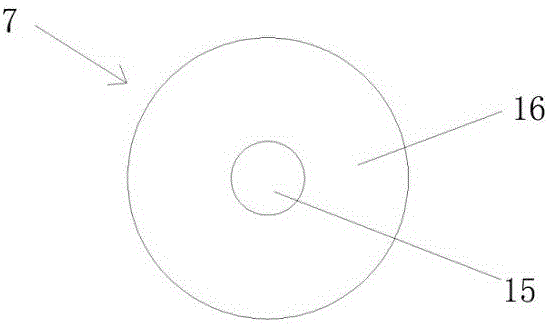

[0017] See Figure 1-2 , The present invention provides a technical solution: a purification equipment for sewage and waste gas in the copper industry, including an air inlet pipe 1, a water inlet pipe 2, a processing box 3, a water outlet pipe 9, an air outlet pipe 10 and a membrane tank 11; the air inlet pipe 1 is set in the processing box 3 At the bottom, a number of small holes are set on the air inlet pipe 1; the water inlet pipe 2 is connected to the processing box 3 and is located at the top of the processing box 3; the processing box 3 includes three layers, from top to bottom, the heavy metal adsorption layer 4 and the SDG adsorbent layer 5 And the purification layer, the heavy metal adsorption layer 4 and the SDG adsorbent layer 5 are located on the upper part of the processing box 3, because the steel mesh is set at the bottom of the SDG adsorbent layer 5, and the steel mesh can fix the SDG adsorbent layer 5 while also allowing Exhaust gas and sewage pass through; th...

Embodiment 2

[0022] See Figure 1-2 , The present invention provides a technical solution: a purification device for sewage and waste gas in the copper industry, including an air inlet pipe 1, a water inlet pipe 2, a processing box 3, a water outlet pipe 9, an air outlet pipe 10 and a membrane tank 11; the air inlet pipe 1 is set in the processing box 3 At the bottom, a number of small holes are set on the air inlet pipe 1; the water inlet pipe 2 is connected to the processing box 3 and is located at the top of the processing box 3; the processing box 3 includes three layers, from top to bottom, the heavy metal adsorption layer 4 and the SDG adsorbent layer 5 And the purification layer, the heavy metal adsorption layer 4 and the SDG adsorbent layer 5 are located on the upper part of the processing box 3, because the steel mesh is set at the bottom of the SDG adsorbent layer 5, and the steel mesh can fix the SDG adsorbent layer 5 while also allowing Exhaust gas and sewage pass through; the m...

Embodiment 3

[0027] See Figure 1-2 , The present invention provides a technical solution: a purification device for sewage and waste gas in the copper industry, including an air inlet pipe 1, a water inlet pipe 2, a processing box 3, a water outlet pipe 9, an air outlet pipe 10 and a membrane tank 11; the air inlet pipe 1 is set in the processing box 3 At the bottom, a number of small holes are set on the air inlet pipe 1; the water inlet pipe 2 is connected to the processing box 3 and is located at the top of the processing box 3; the processing box 3 includes three layers, from top to bottom, the heavy metal adsorption layer 4 and the SDG adsorbent layer 5 And the purification layer, the heavy metal adsorption layer 4 and the SDG adsorbent layer 5 are located in the upper part of the processing box 3, because the steel mesh is set at the bottom of the SDG adsorbent layer 5, and the steel mesh can fix the SDG adsorbent layer 5 while also allowing Exhaust gas and sewage pass through; the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com