Copper industry production wastewater treatment device

A technology for the production of wastewater and treatment equipment, which is applied in the fields of filtration and separation, fixed filter element filters, chemical instruments and methods, etc., can solve the problems of material waste, inability to clean copper scraps and liquid medicine, environmental pollution, etc., and achieves novel and convenient structure. The effect of unified transfer and processing, easy to carry and transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

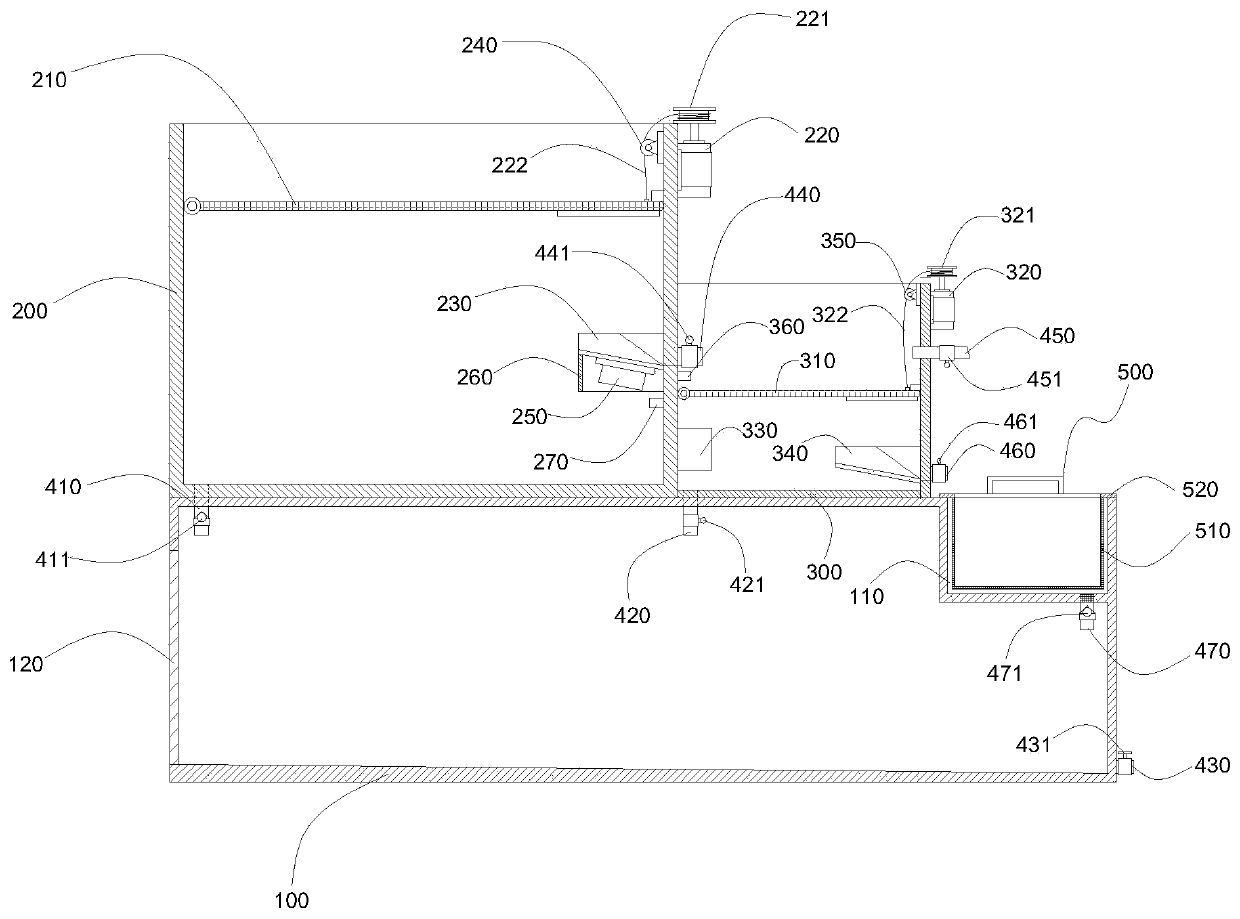

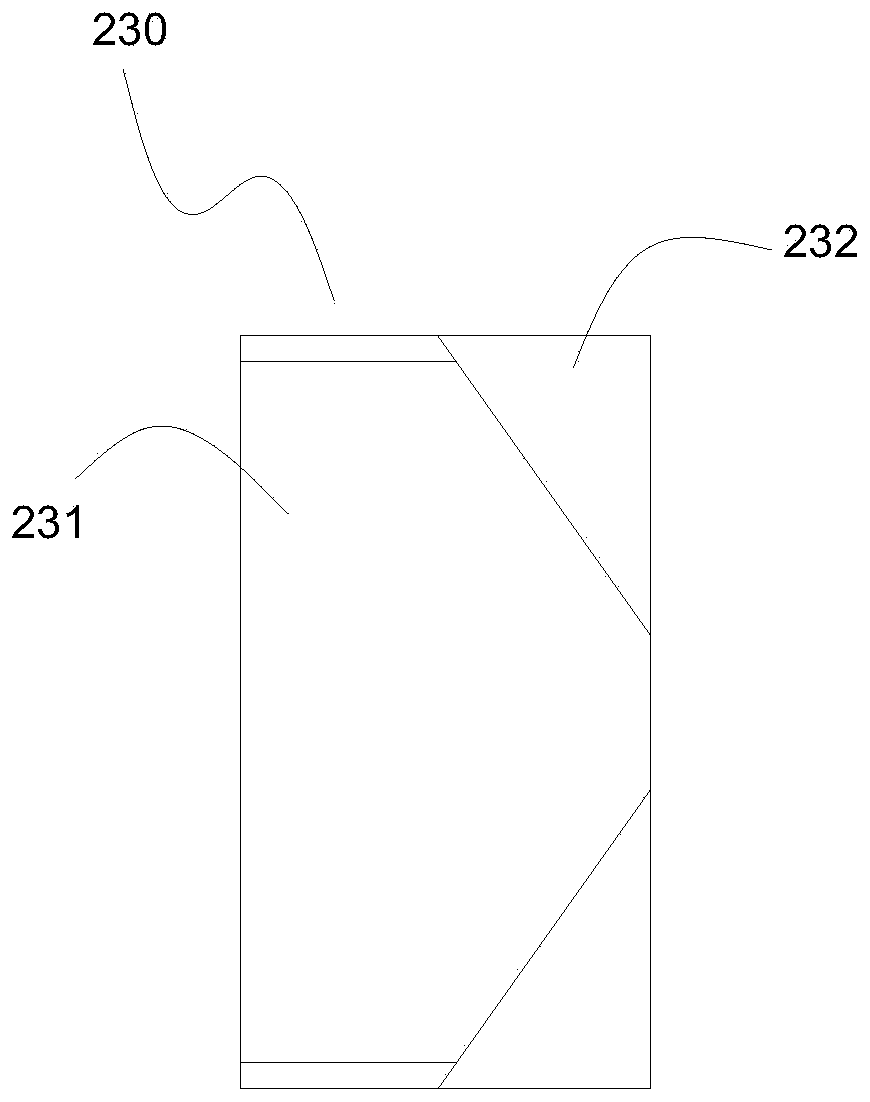

[0022] Such as figure 1 As shown, the specific embodiment of the present invention discloses a copper industry wastewater treatment equipment, including a water storage tank 100, a filter box 200 and a cleaning tank 300 arranged on the top surface of the water storage tank 100, the filter box The bottom of 200 and the water storage tank 100 are connected through a first water pipe 410, the first water pipe 410 is provided with a first one-way valve 411, and the bottom of the cleaning tank 300 and the water storage tank 100 pass through a second water pipe 420 is connected, the second water pipe 420 is provided with a fourth solenoid valve 421, the bottom of the side wall of the water storage tank 100 is connected with a drain pipe 430, and the drain pipe 430 is provided with an on-off valve 431; The filter box 200 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com