Soft magnetic alloy powder and preparation method thereof, magnetic ring inductor and production method thereof

A technology of soft magnetic alloy and alloy powder, which is applied in the direction of inductance with magnetic core, inductance/transformer/magnet manufacturing, transformer/inductance parts, etc., which can solve the problem of low oxygen content and easy puncture of powder dispersive powder Insulation layer, deterioration of soft magnetic properties and other problems, to achieve the effect of strong breakdown resistance, good powder dispersion, and excellent DC superposition characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

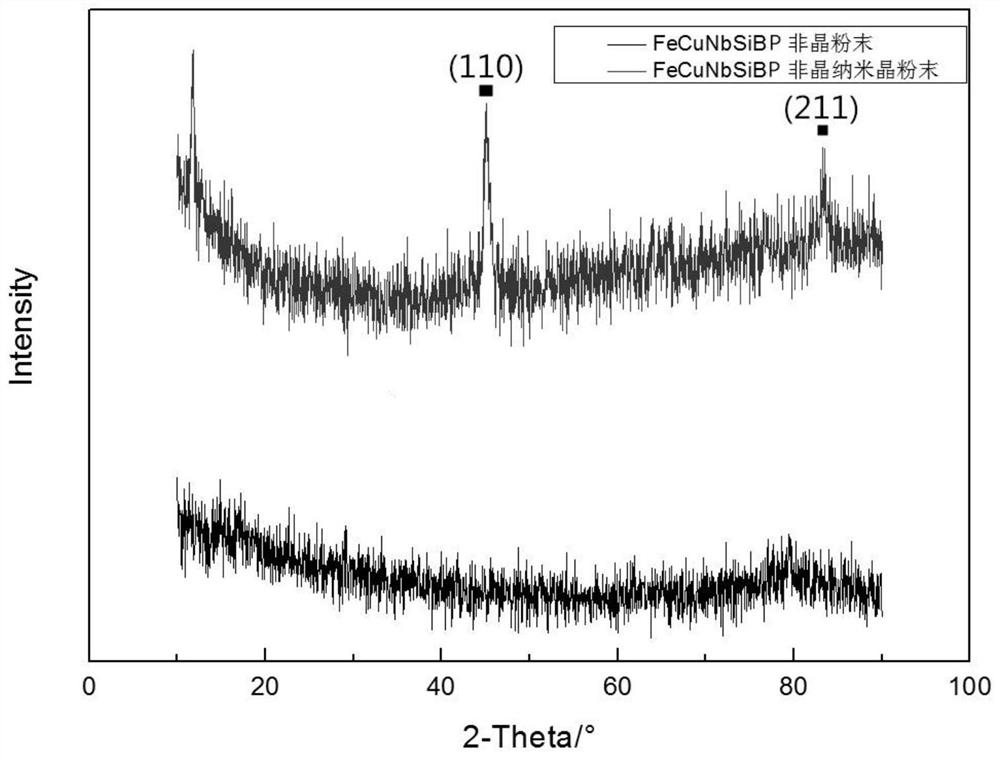

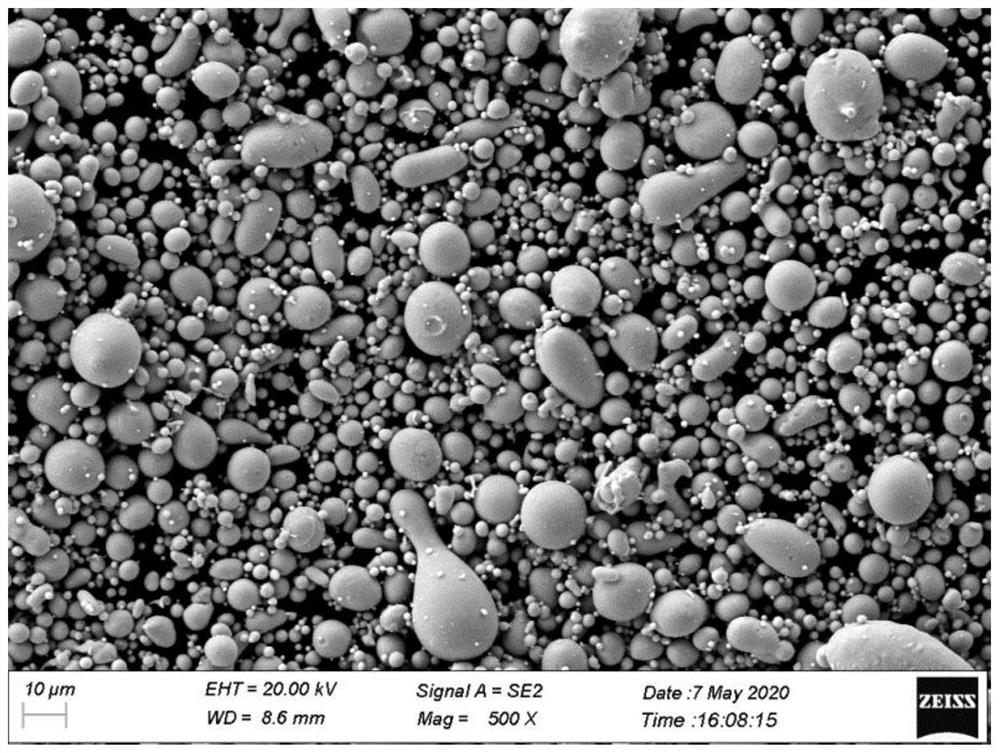

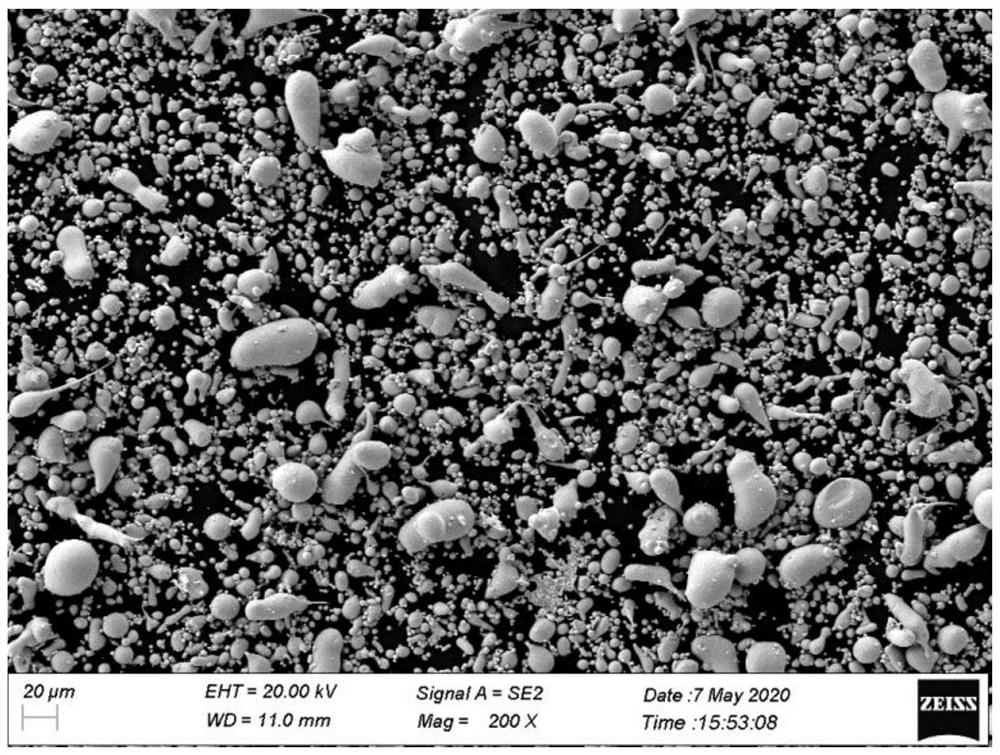

[0040] A method for preparing amorphous nano-soft magnetic alloy powder, the alloy powder components obtained by the method are: 6-9% Si, 1-2.5% B, 1-3% Cu, 4-7% Nb, 0.5-2% P, 82-87.5% Fe. Specific steps are as follows:

[0041] Step 1: Alloy smelting, ingredients are prepared according to the alloy composition, and industrial pure iron, pure copper, industrial ferroboron, single crystal silicon, ferroniobium and ferrophosphorus are selected as raw materials with a purity of 99.9%, and the alloy raw materials are added to the corundum crucible to control the smelting The power is 200-300KW, and the smelting time is 60.0-80.0 minutes. When the temperature of the molten steel reaches 1500-1520°C, the power is reduced to 100-150KW, and the molten steel is slag-forming and deoxidized with an appropriate amount of silicon-calcium and lime. The process takes 10.0 minutes -15.0 minutes, then remove the slag and pour steel. The smelting adopts intermediate frequency induction smelti...

Embodiment 1

[0054] The preparation method of amorphous nano-soft magnetic alloy powder in the present embodiment, concrete steps are as follows:

[0055] Step 1: Alloy smelting. The alloy powder components are: 6.5% Si, 1.7% B, 1.5% Cu, 5.8% Nb, 0.5% P, and the rest is Fe. The ingredients are made according to the alloy composition, and industrial pure iron with a purity of 99.9%, pure copper, industrial ferroboron, single crystal silicon, ferroniobium and ferrophosphorus are selected as raw materials, and the alloy raw materials are added to the corundum crucible, and the smelting power is controlled to 250KW, and the smelting time is long 70 minutes, when the temperature of the molten steel reaches 1500°C, reduce the power to 120KW, use appropriate amount of silicon calcium and lime to deoxidize the molten steel, the process lasts for 10 minutes, then clean the slag and cast steel. The smelting adopts intermediate frequency induction smelting.

[0056] Step 2: Air-spray water-cooled at...

Embodiment 2

[0061] The preparation method of amorphous nano-soft magnetic alloy powder in the present embodiment, concrete steps are as follows:

[0062] Step 1: Alloy smelting. The alloy powder components are: 7% Si, 2.1% B, 1.5% Cu, 5.8% Nb, 0.2% P, and the rest is Fe. The ingredients are made according to the alloy composition, and industrial pure iron with a purity of 99.9%, pure copper, industrial ferroboron, single crystal silicon, ferroniobium and ferrophosphorus are selected as raw materials, and the alloy raw materials are added to the corundum crucible, and the smelting power is controlled to 200KW, and the smelting time is long 60 minutes, when the temperature of the molten steel reaches 1520°C, reduce the power to 100KW, use appropriate amount of silicon calcium and lime to deoxidize the molten steel, the process lasts for 15 minutes, then clean the slag and cast steel. The smelting adopts intermediate frequency induction smelting.

[0063] Step 2: Air-spray water-cooled atom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com