Copper industry data robust coordination and significant error detection method

An error detection and data technology, which is applied in the field of robust coordination and significant detection of non-ferrous copper production data, can solve problems such as difficulty in convergence, high dimensionality, and long detection time, and achieve the effect of reducing cycle detection problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

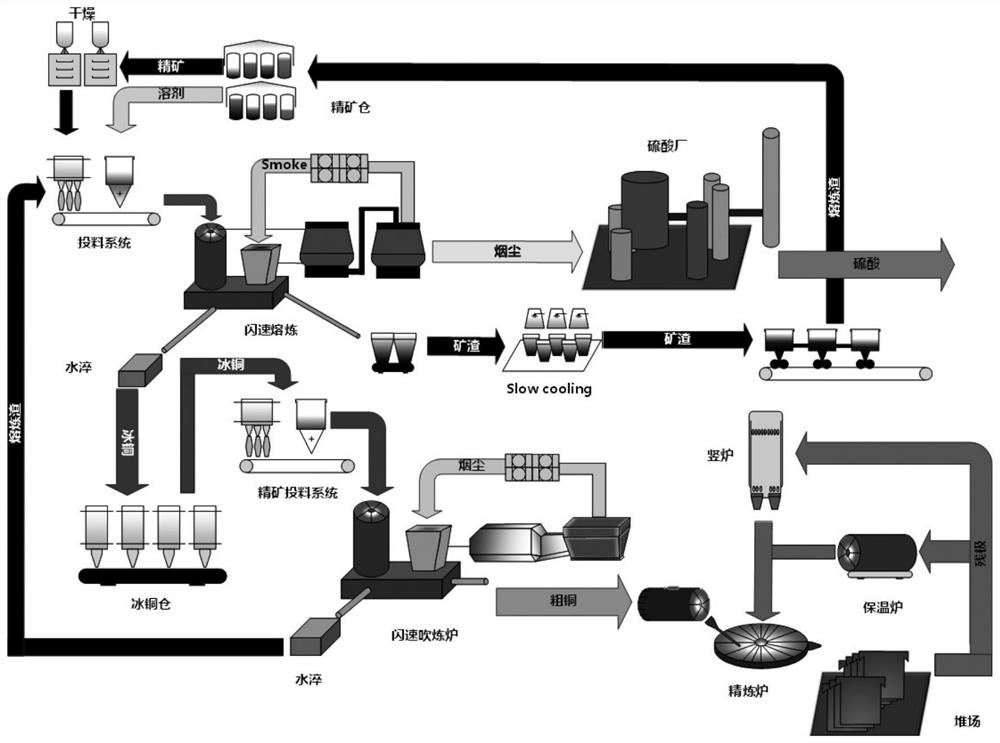

[0069] As shown in the figure, the present invention provides a robust coordination and significant error detection method for copper industry data, which is characterized in that it includes the following steps:

[0070] S1: Data preprocessing

[0071] Read the inventory data of the current month from the SAP database at the production site, including the quality of the material and the grade value of the corresponding valuable elements, and calculate the average value and standard deviation of the measured values, and estimate the recovery rate of each metal element in the smelting plant and the nameless value according to the production situation of the month loss rate;

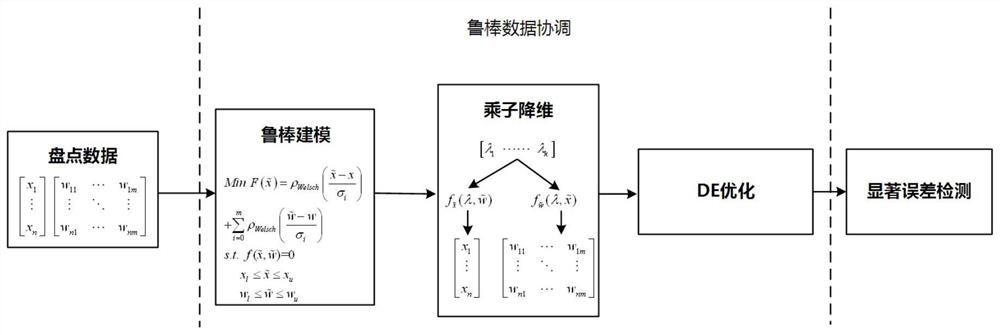

[0072] S2: Data Robust Coordination Modeling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com