Heat self-exchange tube array fin dual ammonia preparation device

A preparation device and self-exchange technology, which is applied in the field of heat self-exchange tube-fin double-type ammonia water preparation device, can solve the problems of liquid ammonia gasification rate changing with ambient temperature, waste of water resources and energy, low concentration of finished ammonia water, etc. , to achieve the effects of improving economic and social benefits, reducing ammonia consumption, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

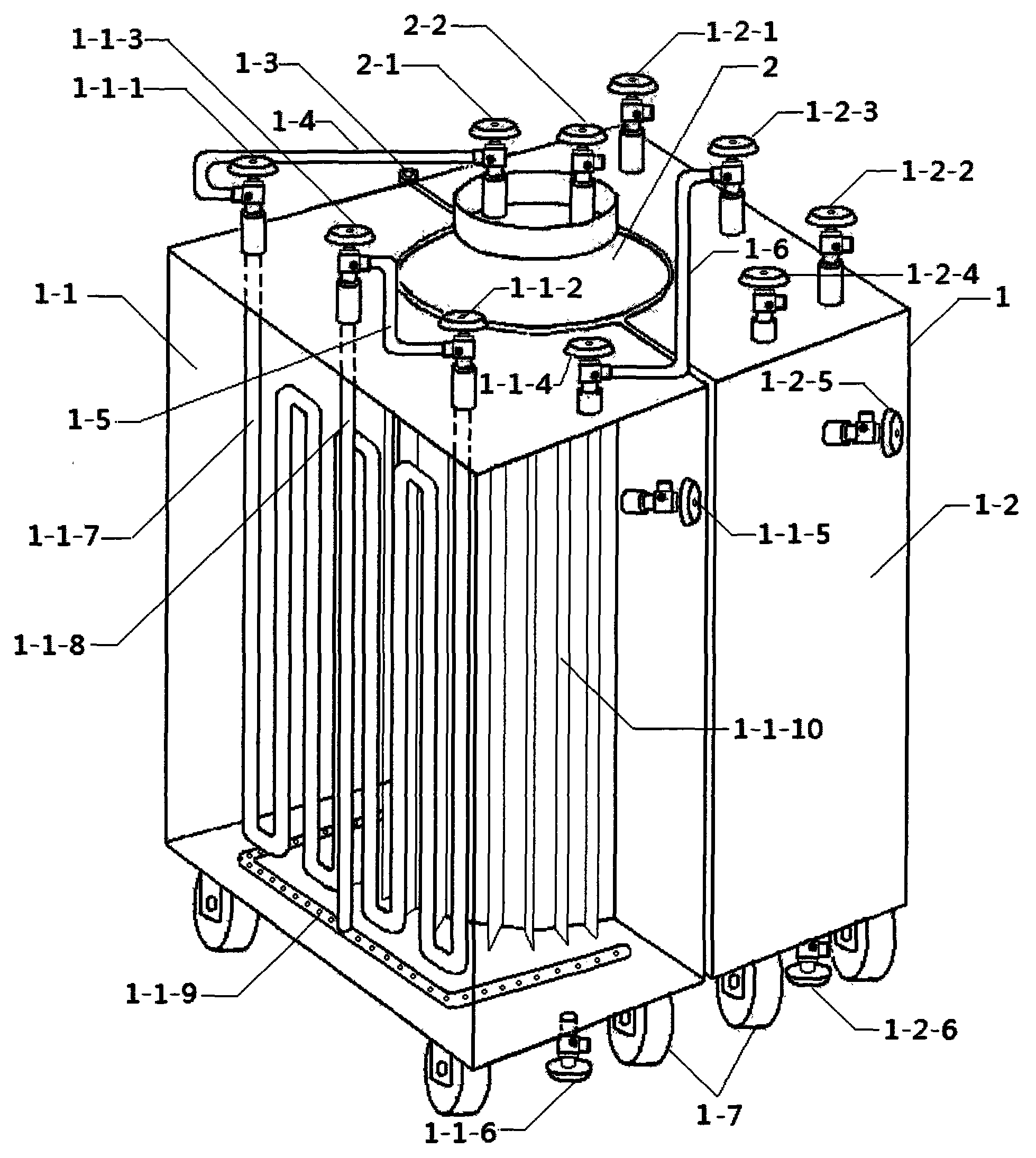

[0014] In order to understand the present invention in detail, further details will be given according to the embodiments and in conjunction with the accompanying drawings. Such as figure 1 As shown, the absorption reactor 1 of the present invention is mainly composed of two cylindrical semicircular absorption reactors 1-1 and 1-2, 1-1 as the primary absorption reactor, and 1-2 as the secondary Absorption reactor; the inside of the two absorption reactors can be in close contact with the outer wall of the liquid ammonia cylinder 2, and the liquid ammonia cylinder 2 is sandwiched between the 1-1 and 1-2 two-stage absorption reactors; the two-stage absorption reactor One side of the two-stage absorption reactor is connected by a rotating shaft 1-3, and the bottom of the two-stage absorption reactor is equipped with universal wheels 1-7 that can make it move. It is convenient to put in or take out from the middle of the two absorption reactors 1-1 and 1-2; the inside of the abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com