Low-energy-consumption desulfurization wastewater zero emission technology and device

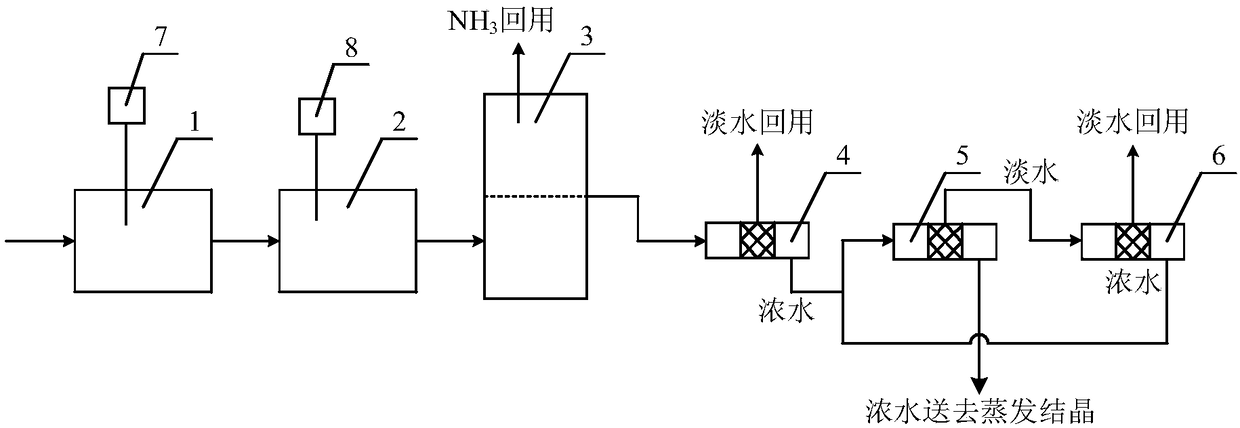

A desulfurization wastewater, zero-discharge technology, applied in degassed water/sewage treatment, water/sewage treatment, heating water/sewage treatment, etc., can solve the problem of high operating pressure of reverse osmosis membrane, increased energy consumption of membrane treatment process, no ammonia nitrogen Pollutant treatment and other issues, to achieve the effect of simplifying dissolved salt components, improving service life, and high concentration ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In a thermal power plant, a new flue gas desulfurization project of a coal-fired boiler unit adopts the low-energy desulfurization wastewater zero discharge process of the present invention, and the specific treatment method of wastewater is as follows;

[0035] (1) The wastewater from the flue gas desulfurization and denitrification system enters the adjustment tank, and the pH value of the wastewater is adjusted to 9 by adding lime milk. Adjust the water output of the water outlet of the regulating tank to keep stable.

[0036] (2) The wastewater enters the sedimentation tank, and the pH of the wastewater is adjusted to 10 by adding sodium carbonate, and kept for 7 hours to completely precipitate calcium and magnesium ions, etc., the supernatant enters the denitrification tower, and the bottom sludge is sent to the sludge treatment unit .

[0037] (3) The wastewater from the sedimentation tank enters the denitrification tower, and the ammonia nitrogen pollutants in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com