Denitration uniformity measurement optimizing system and method under fluctuating loads

A technology of fluctuating load and uniformity, which is applied in the field of automatic measurement and optimization system for the uniformity of nitrogen oxide concentration at the outlet of denitrification, can solve the problems of uniformity analysis result error, large maintenance workload, and long time-consuming test adjustment, so as to avoid errors. Judgment and error adjustment, reduced installation and maintenance workload, accurate results of direct measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

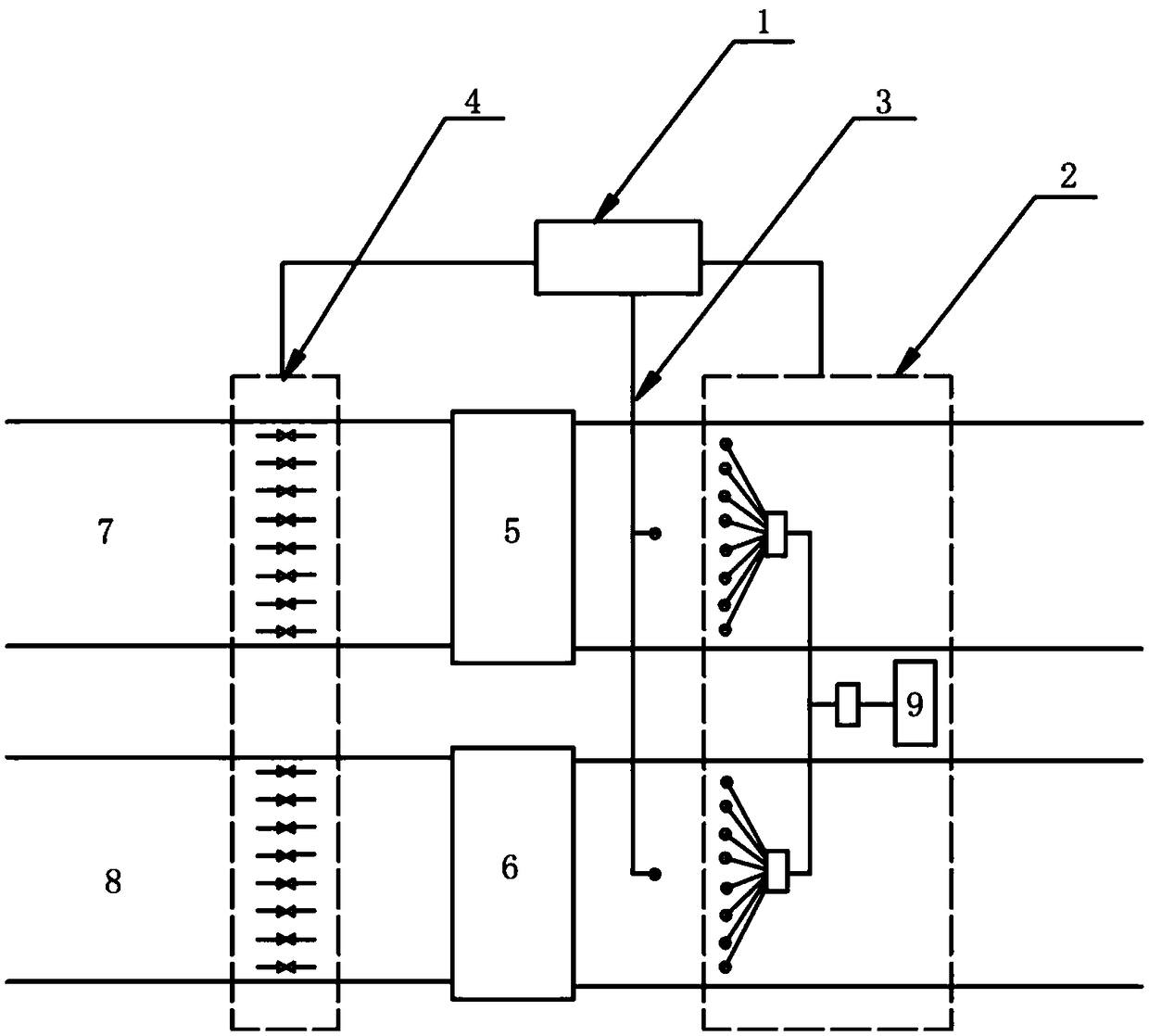

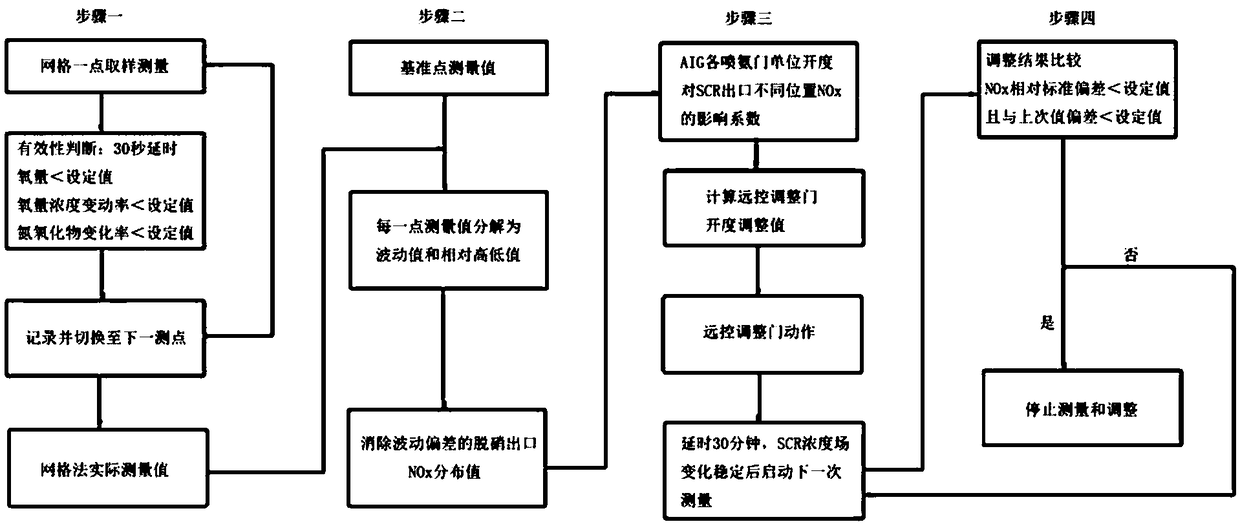

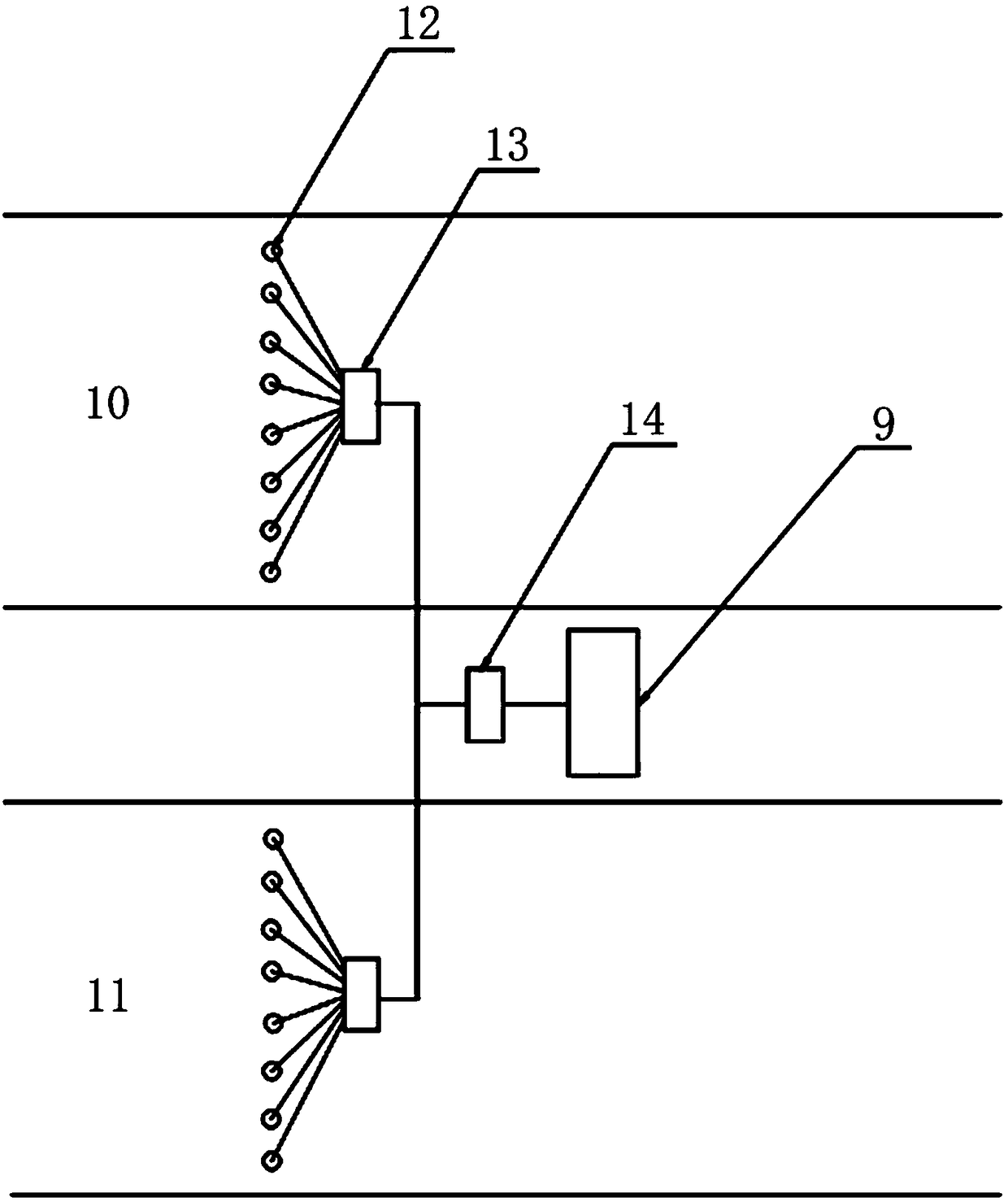

[0034] Combine below Figure 1-3 Describe in detail the technical scheme of the denitrification uniformity measurement optimization system and method under fluctuating loads:

[0035] The present invention aims at the technical problems existing in the prior art that the normal fluctuation of coal-fired boiler load interferes with the measurement results of the uniformity of nitrogen oxides at the outlet of the SCR reactor, etc., and provides a fluctuating method that can accurately measure the uniformity of nitrogen oxides and perform optimal control. Denitrification uniformity measurement optimization system under load. By improving the spatial distribution of ammonia injection, the system makes the ammonia nitrogen ratio (NH3 and NOx concentration ratio) in the reactor evenly distributed, and the NOx uniformity at the outlet of the SCR reactor is controlled at a good level, so that Effectively avoid excessive local ammonia escape at the outlet of the SCR reactor. The techn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com