Method for preparing sulphoaluminate cement by-product ammonia sulfate by partly converting phosphogypsum

A technology of sulphoaluminate cement and phosphogypsum, applied in separation methods, ammonium sulfate, chemical instruments and methods, etc., can solve the problems of increasing the cost of phosphogypsum treatment, limiting the utilization of phosphogypsum waste residue, and difficult control of reducing atmosphere , to achieve the effect of eliminating the discharge of secondary pollutants, reducing ammonia consumption and operational difficulty, and broadening the flexibility of control operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The chemical composition (mass percentage) of phosphogypsum and bauxite used in the present embodiment are respectively as follows:

[0058] Phosphogypsum (dry basis, phosphogypsum without free water):

[0059] CaO: 30.78%, SO 3 : 40.25%, water-soluble P 2 o 5 : 0.36%, insoluble P 2 o 5 : 1.45%,

[0060] Fe 2 o 3 : 1.90%, Al 2 o 3 : 4.01%, SiO 2 : 3.52%, MgO: 0.20%,

[0061] Water of crystallization: 14.98%.

[0062] Bauxite (dry basis, bauxite without free water):

[0063] CaO: 1.18%, SO 3 : 0.65%, Fe 2 o 3 : 2.25%, Al 2 o 3 : 64.56%,

[0064] SiO 2 : 6.58% MgO: 0.34%, TiO 2 : 2.21%, loss on ignition (1000°C): 12.75%.

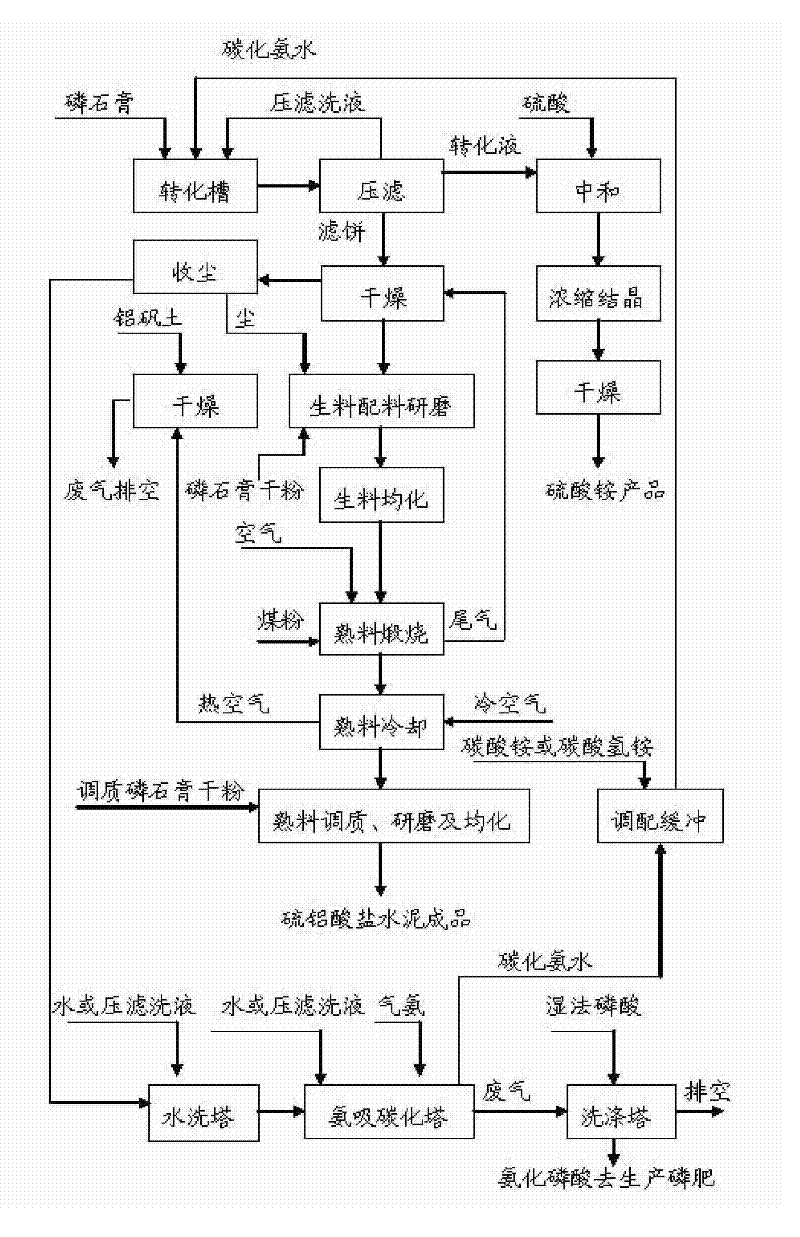

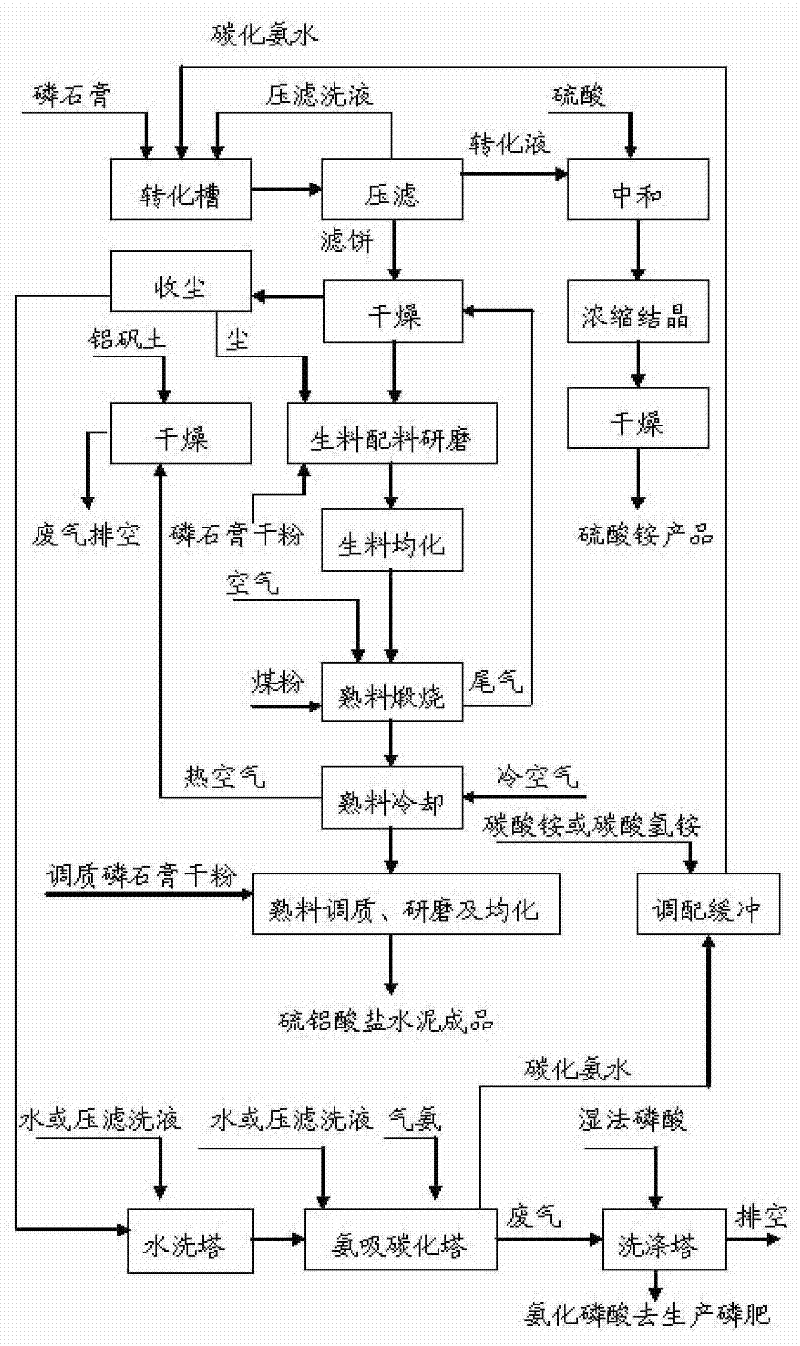

[0065] The method of partial conversion of phosphogypsum in this embodiment to produce sulphoaluminate cement by-product ammonium sulfate is as follows: figure 1 As shown in the schematic diagram of the process flow, the following main steps are included:

[0066] (1) Phosphogypsum conversion

[0067] The carbonized ammonia water...

Embodiment 2

[0101] The chemical composition (mass percentage) of phosphogypsum used in the present embodiment, bauxite is as follows:

[0102] Phosphogypsum (dry basis, phosphogypsum without free water):

[0103] CaO: 31.33% SO 3 : 42.05% water soluble P 2 o 5 : 0.15% insoluble P 2 o 5 : 0.85%

[0104] Fe 2 o 3 : 1.20% Al 2 o 3 : 2.77% SiO 2 : 4.37% MgO: 0.20%

[0105] Crystal water: 15.40%

[0106] Bauxite (dry basis, bauxite without free water):

[0107] CaO: 1.18%, SO 3 : 0.65%, Fe 2 o 3 : 2.25%, Al 2 o 3 : 64.56%,

[0108] SiO 2 : 6.58% MgO: 0.34%, TiO 2 : 2.21%, loss on ignition (1000°C): 12.75%.

[0109] The method of the partial conversion of phosphogypsum to produce sulphoaluminate cement by-product ammonium sulfate in this embodiment is as follows: figure 1 As shown in the schematic diagram of the process flow, it includes the following main steps:

[0110] (1) Phosphogypsum conversion

[0111] The carbonized ammonia water from the ammonia absorption carbo...

Embodiment 3

[0145] The chemical composition (mass percentage) of phosphogypsum used in the present embodiment, bauxite is as follows:

[0146] Phosphogypsum (dry basis, phosphogypsum without free water):

[0147] CaO: 32.28% SO 3 : 43.08% water soluble P 2 o 5 : 0.08% insoluble P 2 o 5 : 0.68% Fe 2 o 3 : 1.15%Al 2 o 3 : 2.15% SiO 2 : 3.88% MgO: 0.14%

[0148] Crystal water: 16.32%

[0149] Bauxite (dry basis, bauxite without free water):

[0150] CaO: 2.39% SO 3 : 0.67% Fe 2 o 3 : 3.21% Al 2 o 3 : 60.20% SiO 2 : 7.51% MgO : 0.40% TiO 2 : 3.38% Loss on ignition (1000°C): 13.20%

[0151] The method of partial conversion of phosphogypsum in this embodiment to produce sulphoaluminate cement by-product ammonium sulfate is as follows: figure 1 As shown in the schematic diagram of the process flow, the following main steps are included:

[0152] (1) Phosphogypsum conversion

[0153] The carbonized ammonia water from the ammonia absorption carbonization tower in the step (10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com