Process and system for treating nitrochlorobenzene ammonolysis wastewater

A wastewater treatment system, technology of nitrochloroaniline, applied in the field of nitrochloroaniline ammonolysis wastewater treatment process and system, can solve the problems of large consumption and achieve the effects of lightening the load, reducing the amount of wastewater, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

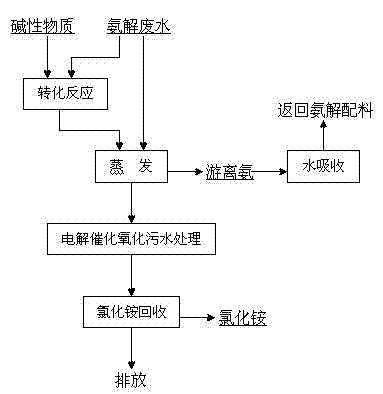

[0017] Embodiment 1 of the present invention: nitrochlorobenzene ammonolysis wastewater treatment process: add sodium hydroxide in the ammonium solution wastewater, make the ammonium ion wherein change into free ammonia, send into vacuum evaporator, waste water is heated to boiling, maintain The boiling time is 8 to 10 hours, so that the free ammonia escapes; the free ammonia in the steam is absorbed by water and returned to the batching process of nitrochloroaniline ammonolysis. The ammonia nitrogen index of the evaporated wastewater can be reduced to 100ppm. After entering the electrolytic catalytic oxidation sewage treatment device to degrade organic substances such as nitrochlorobenzene and nitroaniline, it then enters the ammonium chloride recovery device to recover the remaining ammonium chloride, and then it can be discharged. This process can increase the recovery ratio of ammonia.

[0018] The nitrochloroaniline ammonium solution wastewater treatment system used in th...

Embodiment 2

[0019] Embodiment 2 of the present invention: nitrochlorobenzene ammonolysis wastewater treatment process: add calcium oxide or calcium hydroxide in the ammonium solution wastewater, make the ammonium ion wherein change into free ammonia, send into vacuum evaporator, waste water is heated to Boiling, maintaining the boiling time for 6-8 hours, so that the free ammonia escapes; the free ammonia in the steam is absorbed by water and returned to the batching process of nitrochlorophenyl ammonolysis. After evaporation, the ammonia nitrogen index of wastewater can be reduced to 400ppm. After entering the electrolytic catalytic oxidation sewage treatment device to degrade organic substances such as nitrochlorobenzene and nitroaniline, it then enters the ammonium chloride recovery device to recover the remaining ammonium chloride, and then it can be discharged. This process can increase the recovery ratio of ammonia.

[0020] The nitrochlorobenzene ammonolysis waste water treatment s...

Embodiment 3

[0021] Embodiment 3 of the present invention: Nitrochlorobenzene ammonolysis wastewater treatment process: send the ammonium solution wastewater to ammonia distillation equipment, heat the wastewater to boiling, and maintain the boiling time for 4 to 5 hours to escape the free ammonia in the steam; The free ammonia is absorbed by water and returned to the batching process of nitrochloroaniline ammonolysis for use. After evaporation, the ammonia nitrogen index of wastewater can be reduced to 800ppm. After entering the electrolytic catalytic oxidation sewage treatment device to degrade organic substances such as nitrochlorobenzene and nitroaniline, it then enters the ammonium chloride recovery device to recover ammonium chloride, and then it can be discharged. This process can increase the recovery ratio of ammonium chloride.

[0022] In actual production, the recovery ratio of ammonia and ammonium chloride can be randomly adjusted according to the market prices of liquid ammoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com