Preparation method of ammonium bifluoride

A technology of ammonium bifluoride and ammonium fluoride, which is applied in ammonium fluoride, ammonium halide and other directions, can solve the problems that the product purity is difficult to meet the requirements of high-quality products, the purity of ammonium bifluoride products cannot be obtained, and the dilute ammonia water cannot be reasonably utilized, etc. Low cost, significant economic benefits, and the effect of reducing the decomposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

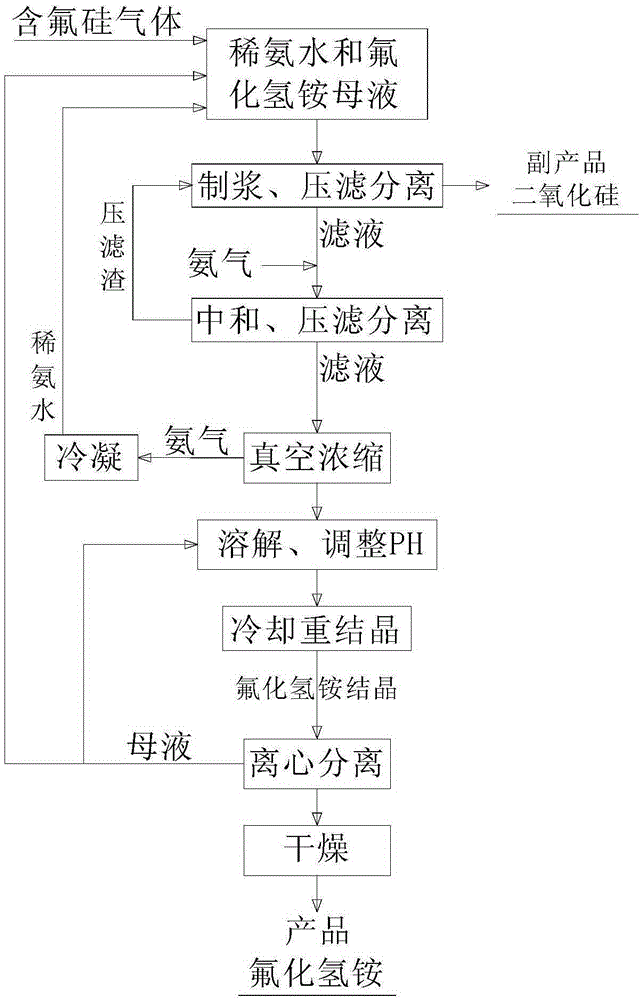

[0024] Such as figure 1 Shown, the preparation method of ammonium bifluoride of the present invention, comprises the steps:

[0025] a. Mix dilute ammonia water and ammonium bifluoride mother liquor, and use the mixture to adsorb gas containing fluorine and silicon, or directly use dilute ammonia water to adsorb gas containing fluorine and silicon to obtain H 2 SiF 6 and (NH 4 ) 2 SiF 6 mixed solution;

[0026] b. mixing the mixed solution obtained in step a with the press filter residue obtained in step d to make slurry, and then separate by press filtration to obtain filtrate and silicon dioxide by-products;

[0027] c, feed ammonia into the filtrate obtained in step b for neutralization, and control the pH value at the end point of the slurry to be 9 to 11;

[0028] d, the slurry obtained in step c is separated by pressure filtration to obtain ammonium fluoride filtrate and filter residue, and the filter residue is returned to step b for pulping;

[0029] e. Vacuum c...

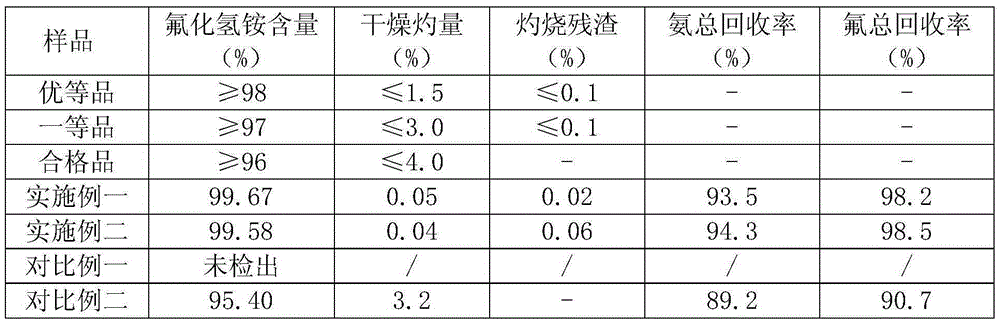

Embodiment 1

[0038] Embodiment 1 Dilute ammonia water absorbs fluorine-containing silicon tail gas of phosphoric acid to prepare ammonium bifluoride

[0039] NH 3 Dilute ammonia water with a concentration of 3.5% is used to absorb fluorine-containing silicon gas in phosphoric acid, and the concentration of the obtained absorption liquid F is 13.52%. Use fluorine-absorbing liquid and ammonia-containing silica to make pulp (i.e. the press filter residue obtained in step d of the present invention), the weight ratio is 1:2, press-filter the slurry after pulping, reclaim F and ammonia in the ammonia-containing silica NH 3 . The filtrate is passed into ammonia gas for neutralization, and the terminal pH value of the neutralization reaction slurry is 11.5, and the neutralization reaction slurry is press-filtered to obtain an ammonium fluoride filtrate with a F concentration of 15.39%, which is used for vacuum concentration to prepare ammonium bifluoride, leaving NH 3The ammoniated silica at ...

Embodiment 2

[0040] Example Dilute ammonia water and ammonium bifluoride crystallization mother liquor mixed solution absorbs phosphoric acid fluorine-containing silicon tail gas to prepare ammonium bifluoride

[0041] NH 3 The mixture of dilute ammonia water with a concentration of 3.5% and ammonium bifluoride mother liquor with a F concentration of 21.75% is used to absorb fluorine-containing gas in phosphoric acid, and the F concentration is 19.67%. Use fluorine-absorbing liquid and ammonia-containing waste residue (i.e. the filter press residue obtained in step d of the present invention) to make slurry, the weight ratio is 1.5:2, press filter the slurry after repulping, and reclaim F and NH in the ammonia-containing waste residue 3 . The filtrate is passed into ammonia gas for neutralization, and the terminal pH value of the neutralization reaction slurry is 11.2, and the neutralization reaction slurry is press-filtered to obtain an ammonium fluoride filtrate with a F concentration o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com