Process for preparing complex fertilizer using sulfuric acid and ammine as partial raw material

A compound fertilizer and raw material technology, applied in the direction of ammonium orthophosphate fertilizer, alkaline orthophosphate fertilizer, fertilizer form, etc., can solve the problems of serious ammonia loss, high reaction heat, equipment corrosion, etc., and achieve reduction of ammonia consumption and utilization rate The effect of improving and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

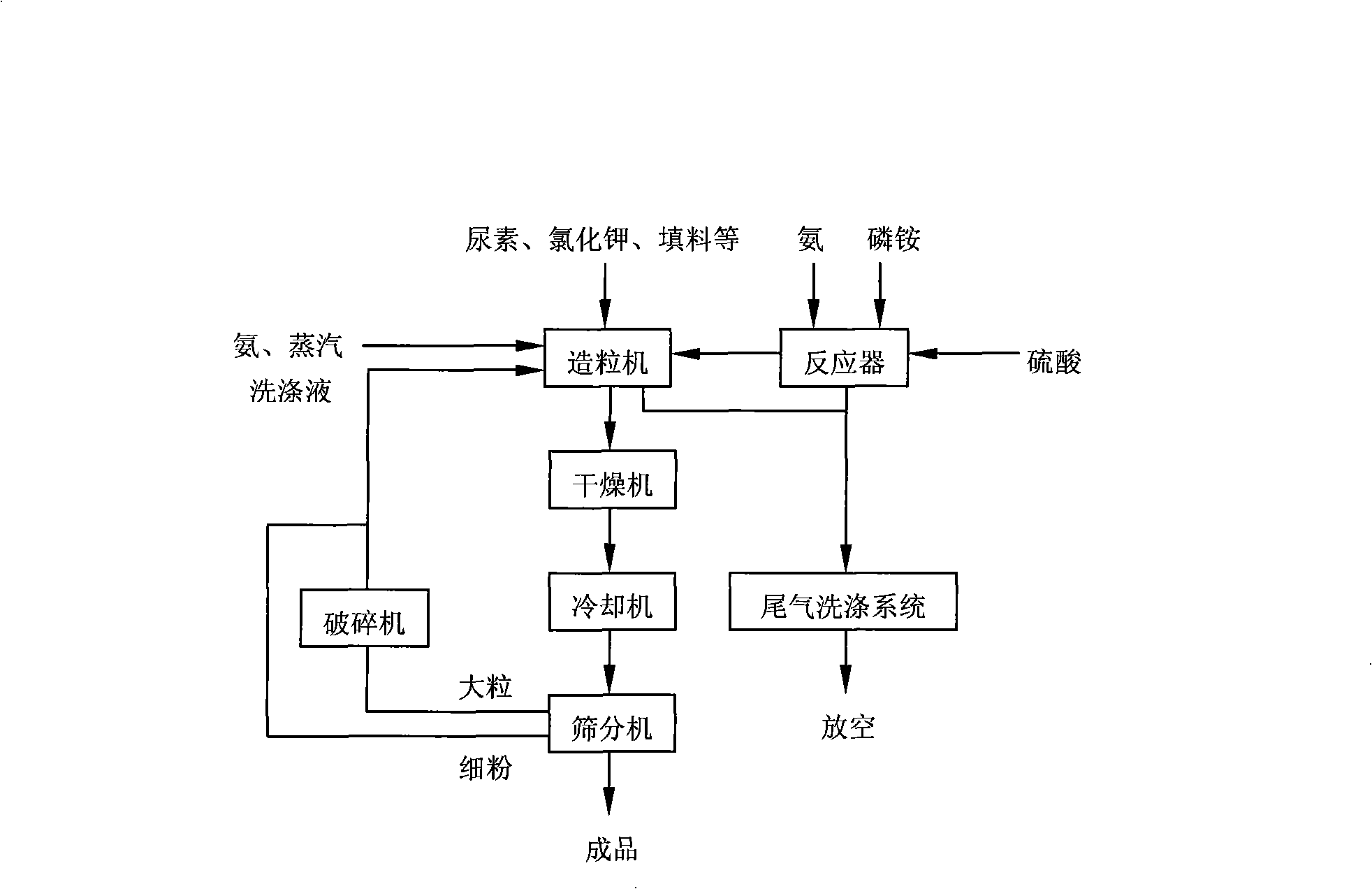

[0026] process such as figure 1 Shown:

[0027] The composition of raw materials into the system is as follows:

[0028] Urea (N: 46%)

4.634

t / h

Monoammonium (N: 10%P 2 o 5 :50%)

2.842

t / h

Potassium Chloride (K 2 O>60%)

4.718

t / h

Sulfuric acid (93%)

1.288

t / h

NH 3

0.532

t / h

filler

0.14

t / h

[0029] Product specification: N-P 2 o 5 -K 2 O=20-10-20

[0030] Hourly product output: 14 tons / hour

[0031] Reactor temperature: 60~90℃

[0032] Granulation material temperature: ~65°C

[0033] Moisture content of granulation material: ~2.5%

[0034] Return material quantity: ~10 tons / hour.

Embodiment 2

[0036] The process flow of this embodiment is as figure 1 shown, but omitting the drying step:

[0037] The composition of raw materials into the system is as follows:

[0038] Urea (N: 46%)

1.26

t / h

Ammonium Phosphate (N: 11%P 2 o 5 : 44%)

4.844

t / h

[0039] Potassium Chloride (K 2 O>60%)

3.556

t / h

2.436

t / h

NH 3

0.56

t / h

Sulfuric acid (93%)

1.75

t / h

[0040] Product specification: N-P 2 o 5 -K 2 O=15-15-15

[0041] Hourly product output: 14 tons / hour

[0042] Reactor temperature: 60~90℃

[0043] Granulation material temperature: ~75°C

[0044] Moisture content of granulation material: ~2.0%

[0045] The amount of returned materials: ~7 tons / hour.

Embodiment 3

[0047] Please refer to figure 1 First, ammonium phosphate and 80% sulfuric acid are prepared into ammonium phosphate and phosphoric acid slurry. The amount of sulfuric acid added is 30 kilograms per ton of product. Part of ammonia can also be added but the fluidity of the slurry must be maintained. Then the slurry is sprayed on the material bed in the granulator, and the phosphoric acid in the slurry is neutralized with the ammonia sprayed from the ammonia spray pipe buried in the material bed. The amount of ammonia added is 20 kg per ton of product. At the same time, it is mixed and granulated, and then dried, cooled and sieved to obtain the finished compound fertilizer.

[0048] Most of the raw materials for the production of compound fertilizers contain ammonium phosphate, which is a mixture of monoammonium phosphate and diammonium phosphate, and also contains some iron, aluminum, and magnesium impurities.

[0049] Ammonium sulfate itself is one of the components of compou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com